Laminated structure sound insulation device

A laminated structure and sound insulation technology, applied in the direction of sound insulation, insulation layer, building components, etc., can solve the problems of high noise in the power distribution room, easy to trouble the residents, etc., to enhance the sound insulation performance, improve the sound insulation performance, and improve the damping. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

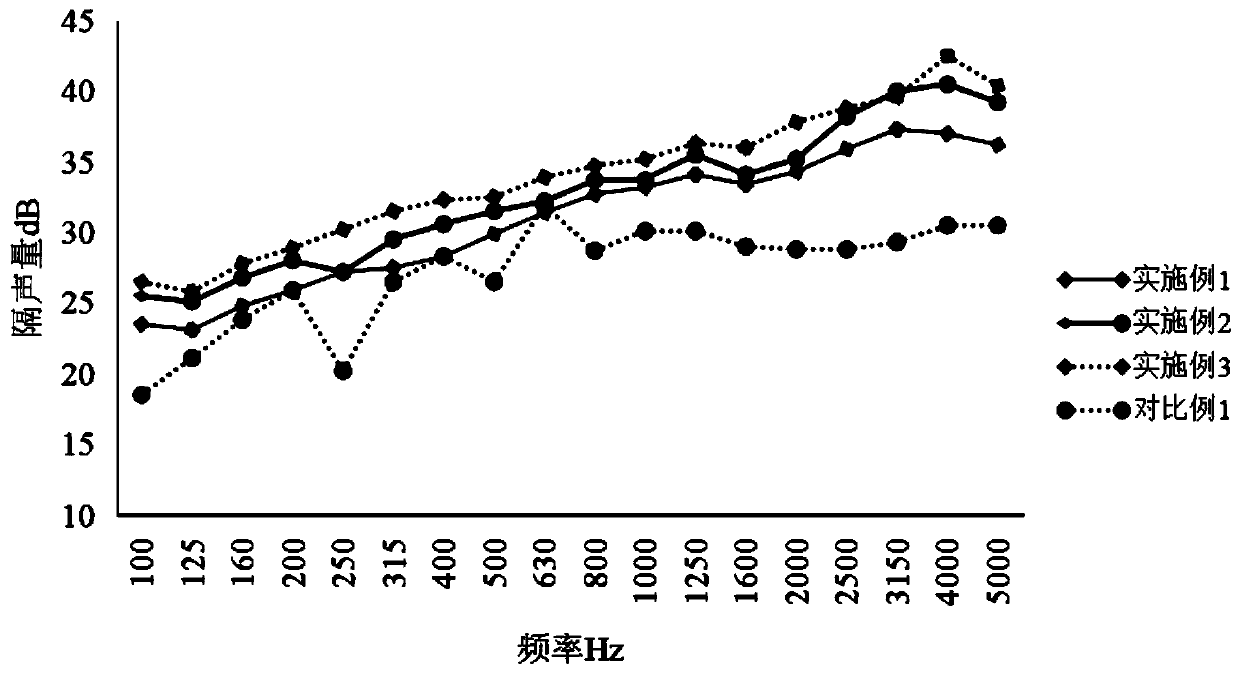

Embodiment 1

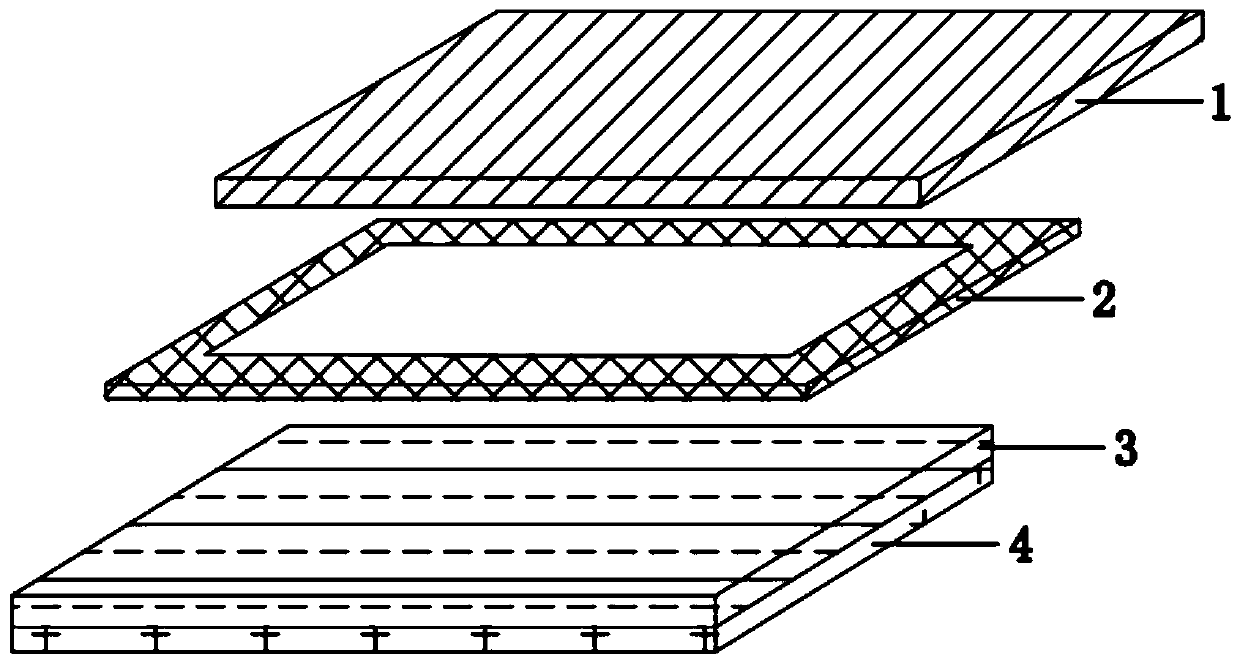

[0034] like figure 1 As shown, this embodiment relates to a sound insulation device with a laminated structure, including a composite damping sound insulation material layer 1 , a hot melt adhesive layer 2 , a rubber damping layer 3 and a metal sound insulation layer 4 stacked in sequence.

[0035] Wherein, in this embodiment, the composite damping and sound-insulating material layer 1 is an ethylene-vinyl acetate resin / metal powder / rubber powder composite sound-insulating material layer, and the composite damping and sound-insulating material includes 100g of ethylene-vinyl acetate resin, 200g of metal powder and 40g of rubber powder, the thickness of the composite damping and sound-insulating material layer 1 is 5mm. Composite damping sound insulation material layer 1 is prepared according to the following steps:

[0036] (1) Put ethylene-vinyl acetate resin particles, metal powder, and rubber powder into a high-speed mixer and mix for 30 minutes according to the ratio of p...

Embodiment 2

[0043] This embodiment relates to a laminated structure sound insulation device. The difference between this embodiment and Embodiment 1 is that in this embodiment,

[0044] The composite damping and sound-insulating material layer is ethylene-vinyl acetate resin / metal powder / rubber powder composite sound-insulating material layer, and the composite damping and sound-insulating material includes 100g ethylene-vinyl acetate resin, 200g metal powder and 40g rubber powder. The thickness is 5mm. The composite damping sound insulation material layer is prepared according to the following steps:

[0045] (1) Put ethylene-vinyl acetate resin particles, metal powder, and rubber powder into a high-speed mixer and mix for 30 minutes according to the ratio of parts by mass in the formula, then take it out;

[0046] (2) Use a double-drum mill heated to 100°C to repeatedly mill the powder mixed in step (1) to plasticize it into sheets.

[0047] (3) Take an appropriate amount of open-smel...

Embodiment 3

[0052] This embodiment relates to a laminated structure sound insulation device. The difference between this embodiment and Embodiment 1 is that in this embodiment,

[0053] The composite damping and sound-insulating material layer is ethylene-vinyl acetate resin / metal powder / rubber powder composite sound-insulating material layer, and the composite damping and sound-insulating material includes 100g ethylene-vinyl acetate resin, 200g metal powder and 40g rubber powder. The thickness is 8mm. The composite damping sound insulation material layer is prepared according to the following steps:

[0054] (1) Put ethylene-vinyl acetate resin particles, metal powder, and rubber powder into a high-speed mixer and mix for 30 minutes according to the ratio of parts by mass in the formula, then take it out;

[0055] (2) Use a double-drum mill heated to 100°C to repeatedly mill the powder mixed in step (1) to plasticize it into sheets.

[0056] (3) Take an appropriate amount of open-smel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com