Mold assembly improved structure for greatly improving casting precision of light aluminum piston

A light-weight and large-scale technology, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor water cooling effect of the core mold, insufficient pushing of the slider mold, and unstable casting dimensions, etc., to achieve quality Larger, enhanced anti-turbulence performance, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

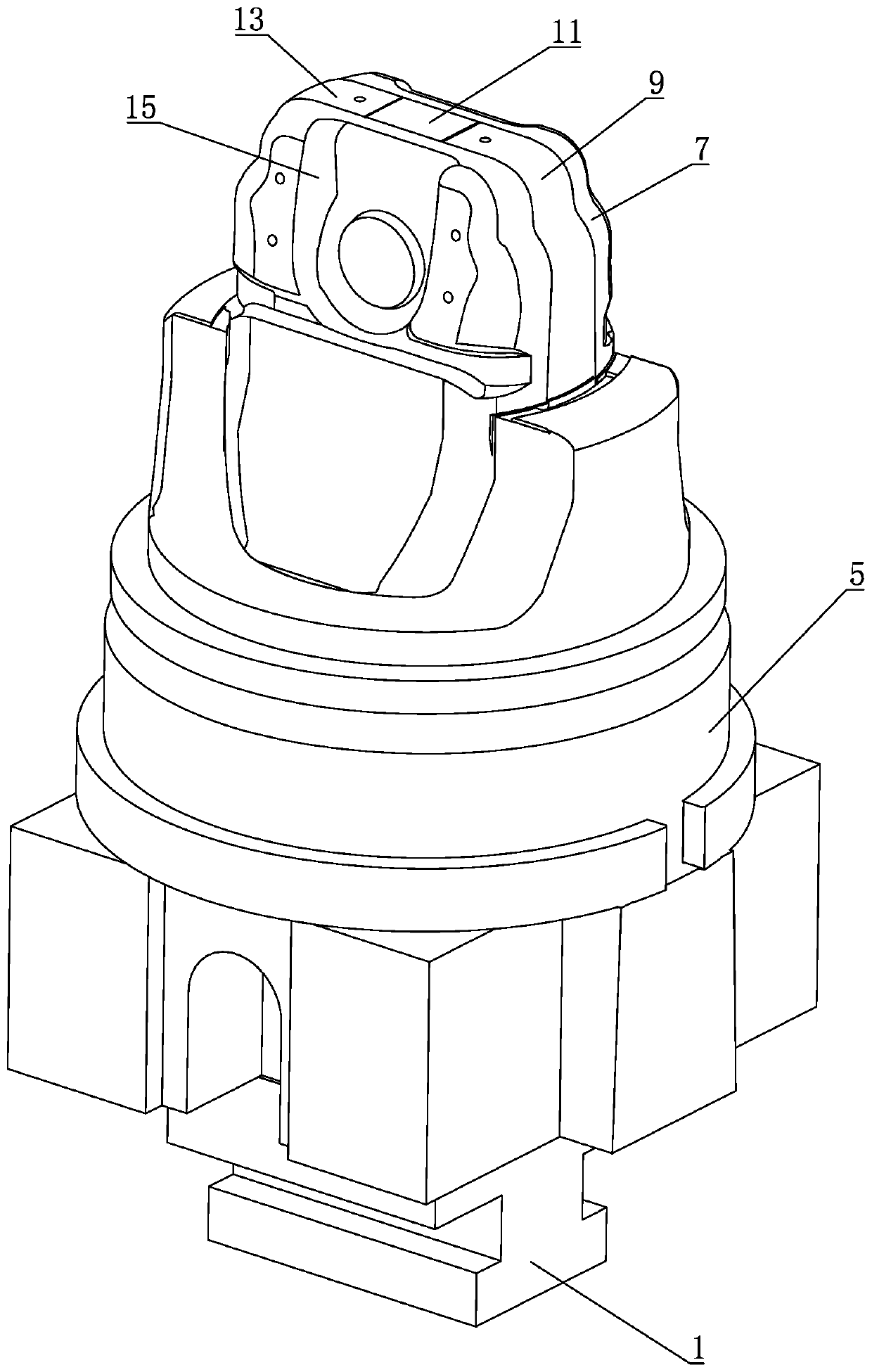

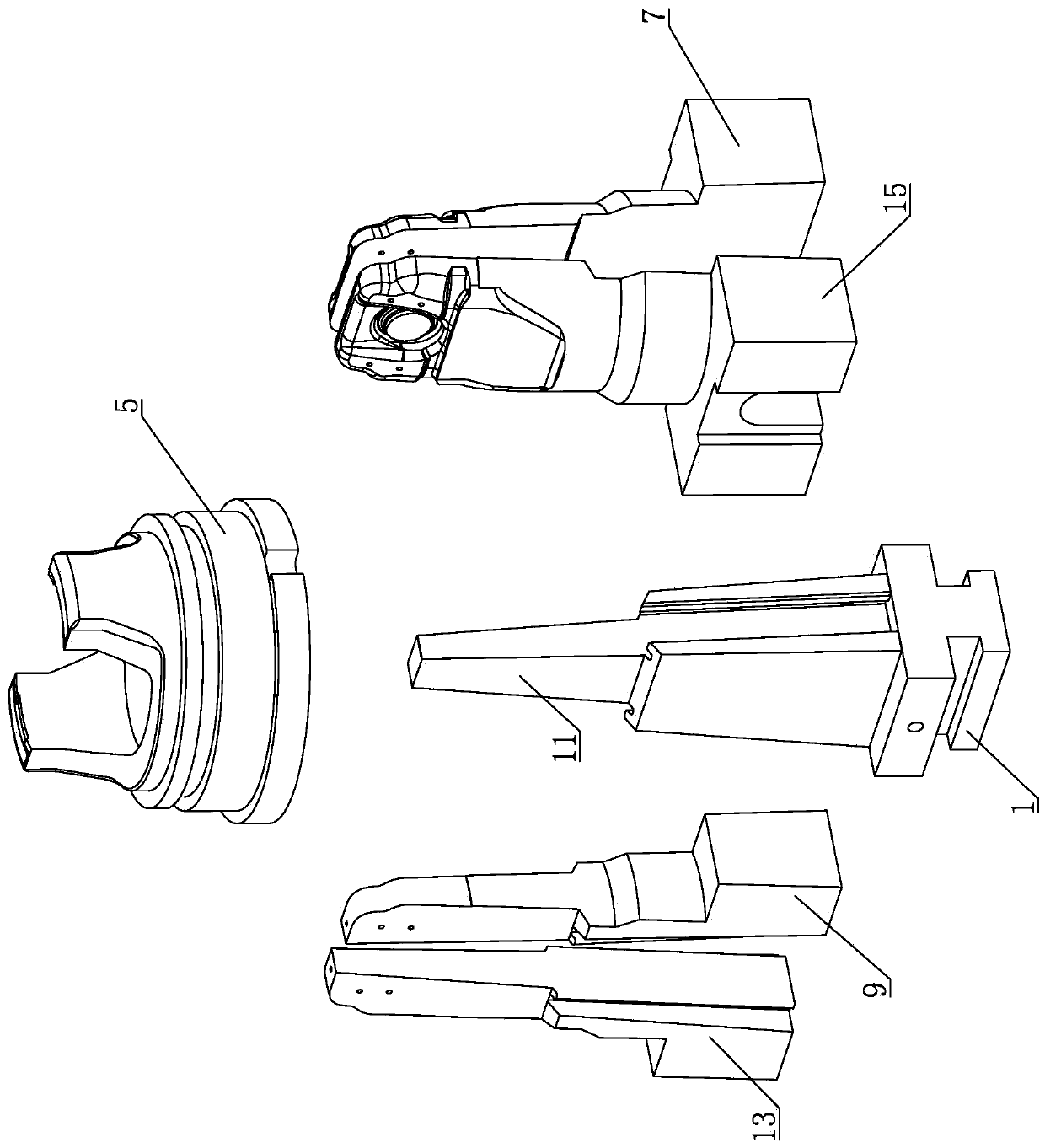

[0078] The improved structure of the mold assembly that greatly improves the casting precision of lightweight aluminum pistons, the mold assembly consists of an upper mold (52), an outer mold I (45), a pin hole mold I (41), a slider mold I (44), an outer mold Die II (47), pin hole mold II (51), slide block mold II (48), core mold (46) eight components form.

[0079] Outer mold 1 (45), slide block mold 1 (44), pin hole mold 1 (41) are combined together. The slide block mold 1 has the pin hole I (79) that the pin of the pin hole mold 1 passes through; there is a circle that moves forward and backward by the horizontal round bar (61) of the pin hole mold 1 and then drives the slide block mold 1 to lift. Rod slit track (75); also have the slanted column body I (77) that is used for linear sliding in outer mold I cavity; Slider mold I is closed in outer mold I cavity by briquetting frame I (43), and briquetting Frame I is fixed on the surface of outer mold I by fasteners; inclined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com