Ultrasonic cake-cutting machine convenient for inserting paper

An ultrasonic and cutting machine technology, which is applied in the division/slicing of baked food, conveyor objects, sending objects, etc., can solve the problem of low paper insertion efficiency and achieve the effect of convenient paper insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

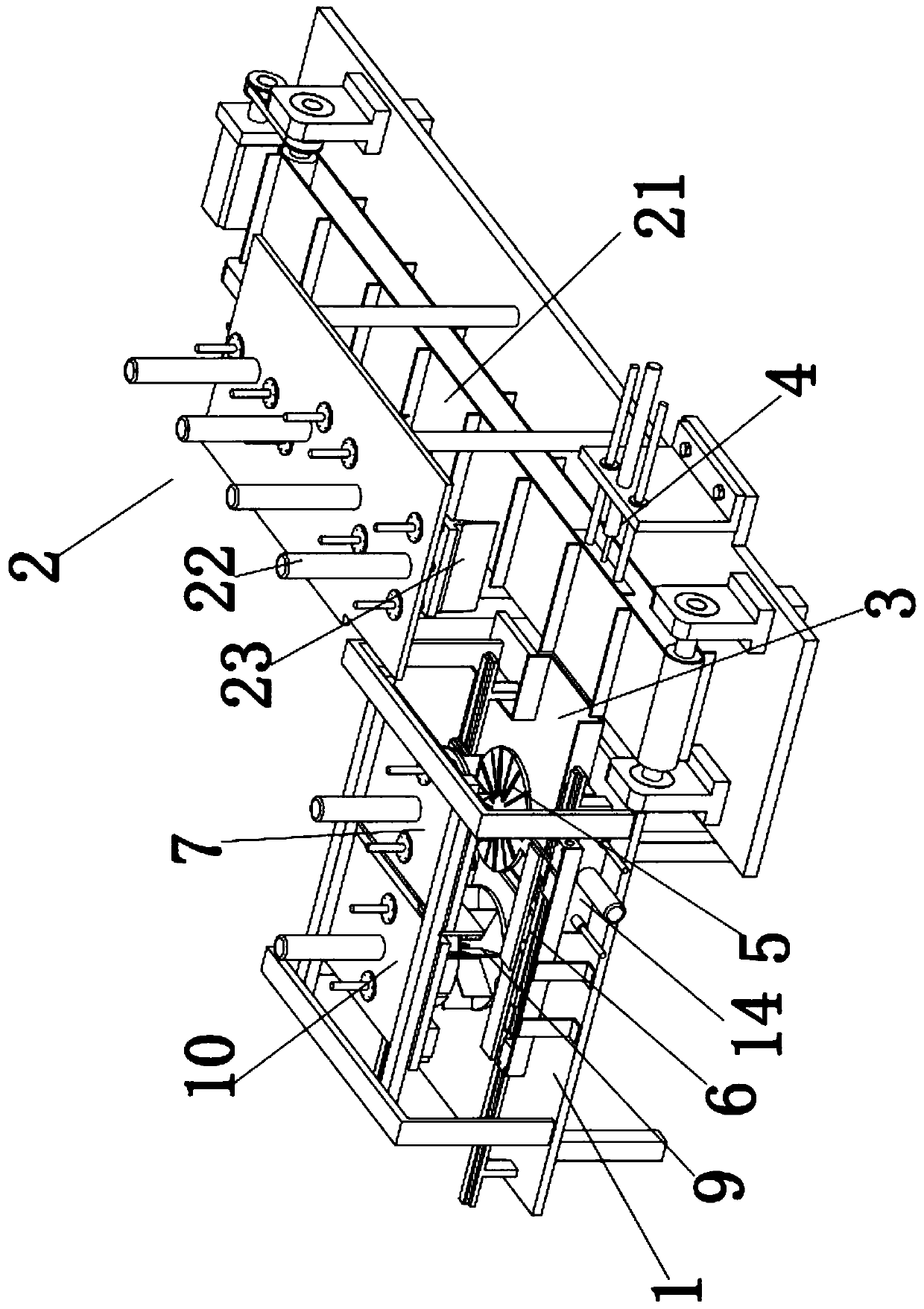

[0047] An ultrasonic cake cutter for easy paper insertion, including:

[0048] Rack 1;

[0049]Cutting assembly 2, the cutting assembly 2 is installed on the frame 1;

[0050] The first guide seat 3, the first guide seat 3 is located on one side of the cutting assembly 2;

[0051] The first pusher assembly 4, the first pusher assembly 4 is located on the other side of the cutting assembly 2;

[0052] The material receiving plate 5 is located above the first guide seat 3, the material receiving plate 5 is provided with a first through hole 51, and the material receiving plate 5 is slidably connected with the frame 1;

[0053] The first driving assembly 6, the first driving assembly 6 is installed on the frame 1, the first driving assembly 6 is connected with the material receiving plate 5 for driving the material receiving plate 5 to slide;

[0054] The paper insertion assembly 7, the paper insertion assembly 7 is located above the receiving plate 5;

[0055] The first slid...

Embodiment 2

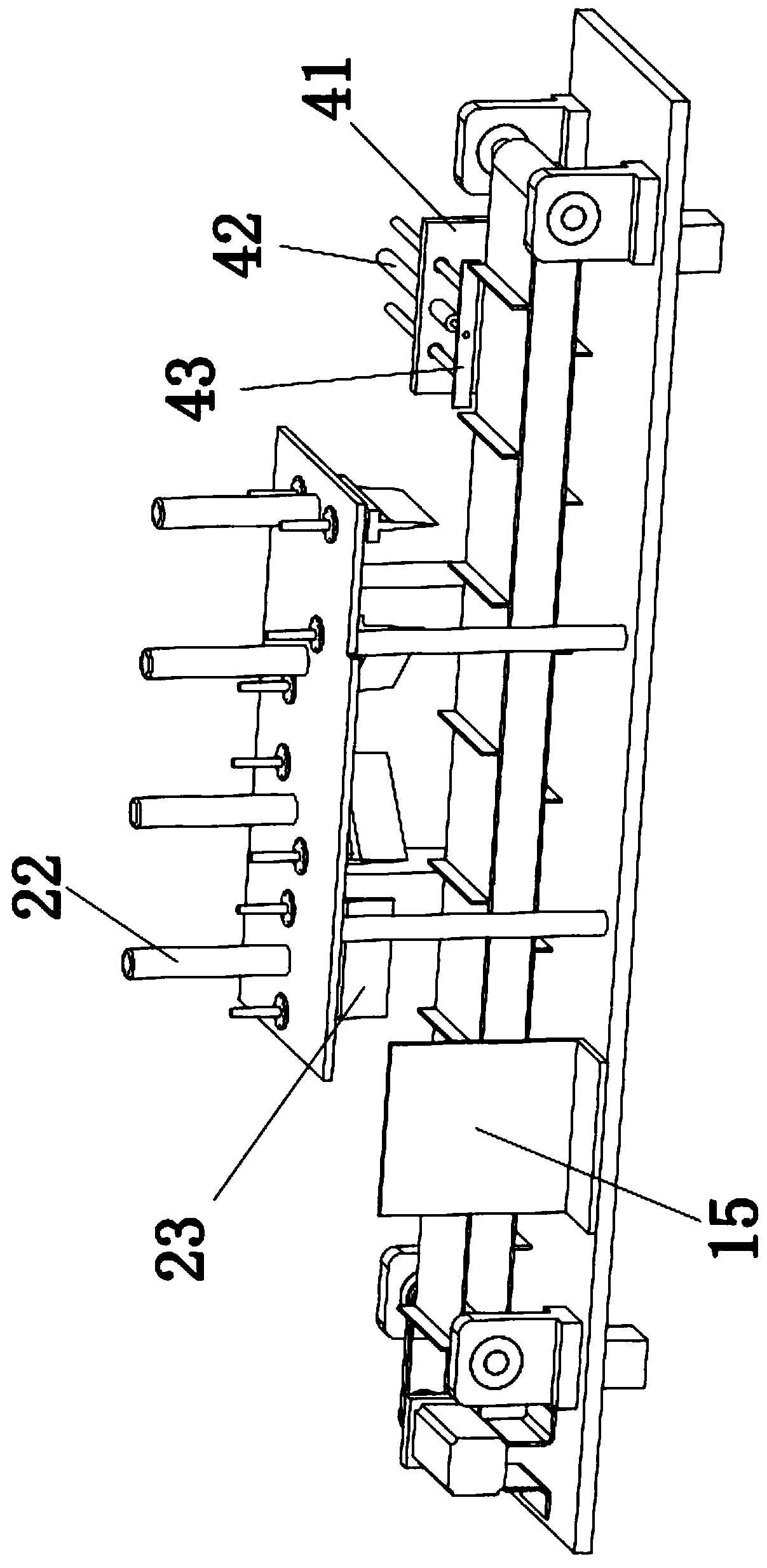

[0070] Such as Figure 9 with Figure 10 As shown, in this embodiment, the cutting assembly 2 includes a conveyor belt assembly 21 and a cutting knife assembly, the cutting knife assembly is installed above the conveyor belt assembly 21, guide grooves are provided on the conveyor belt assembly 21, and at least four groups of cutting knife assemblies are arranged at intervals .

[0071] In this way, the conveyor belt assembly 21 drives the cake to move to the bottom of different cutting knife assemblies in turn, and the cutting knife assembly cuts the cake. When the cake is cut by the last cutting knife assembly, the whole cake is cut. In the transmission of the conveyor belt assembly 21, the cakes arranged sequentially on the conveyor belt assembly 21 are cut by the cutting knife assembly one by one, and the cake located at the front has been cut. This cutting method has higher cutting efficiency.

[0072] In addition, the first pushing assembly 4 includes a second fixing se...

Embodiment 3

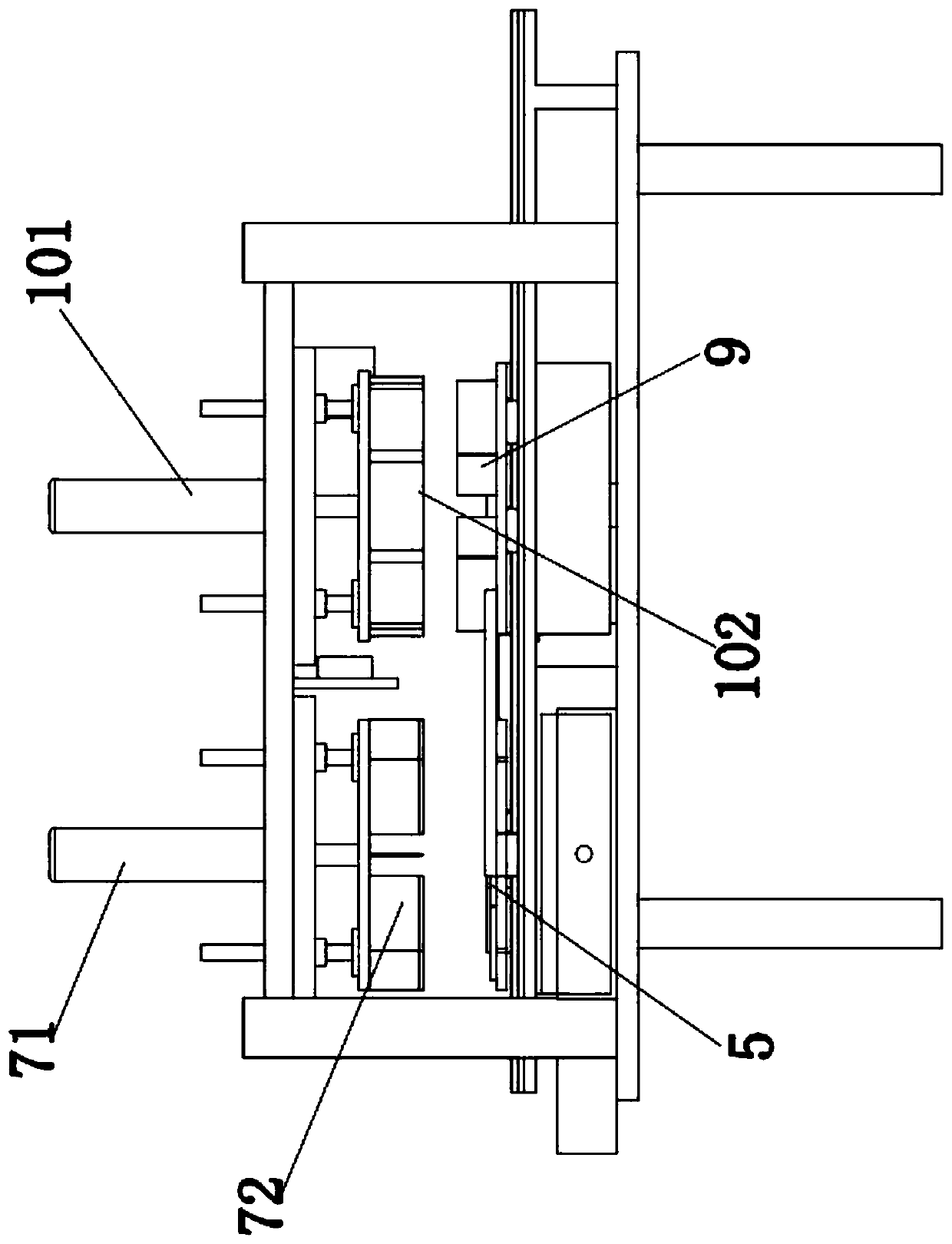

[0079] In this embodiment, the ultrasonic cutter 23 includes a cutter body 231, a transducer housing 232, a transducer, a horn 233 and a cooling assembly, and the output shaft of the fifth linear motion power device 22 is connected to the transducer housing 232 , the transducer is fixed in the transducer shell 232, the horn 233 is fixed on the transducer shell 232, the horn 233 is connected with the transducer, the cutter body 231 is connected with the horn 233; the cutter body 231 The upper end is provided with a receiving cavity 2311 and a second through hole connected to the receiving cavity 2311. There are two receiving cavities 2311 at intervals. The receiving cavity 2311 is provided with openings. The openings of the two receiving cavities 2311 face two opposite directions to dissipate heat. The components are provided with two groups, and the two groups of cooling components are respectively installed corresponding to the two accommodating cavities 2311; the cooling comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com