Self-propelled bundling machine

A self-propelled, baler technology, used in packaging, loaders, agricultural machinery and implements, etc., can solve problems such as the inability of the baler to work independently, the inability to continuously complete the collection operation, and the shutdown of the round baler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

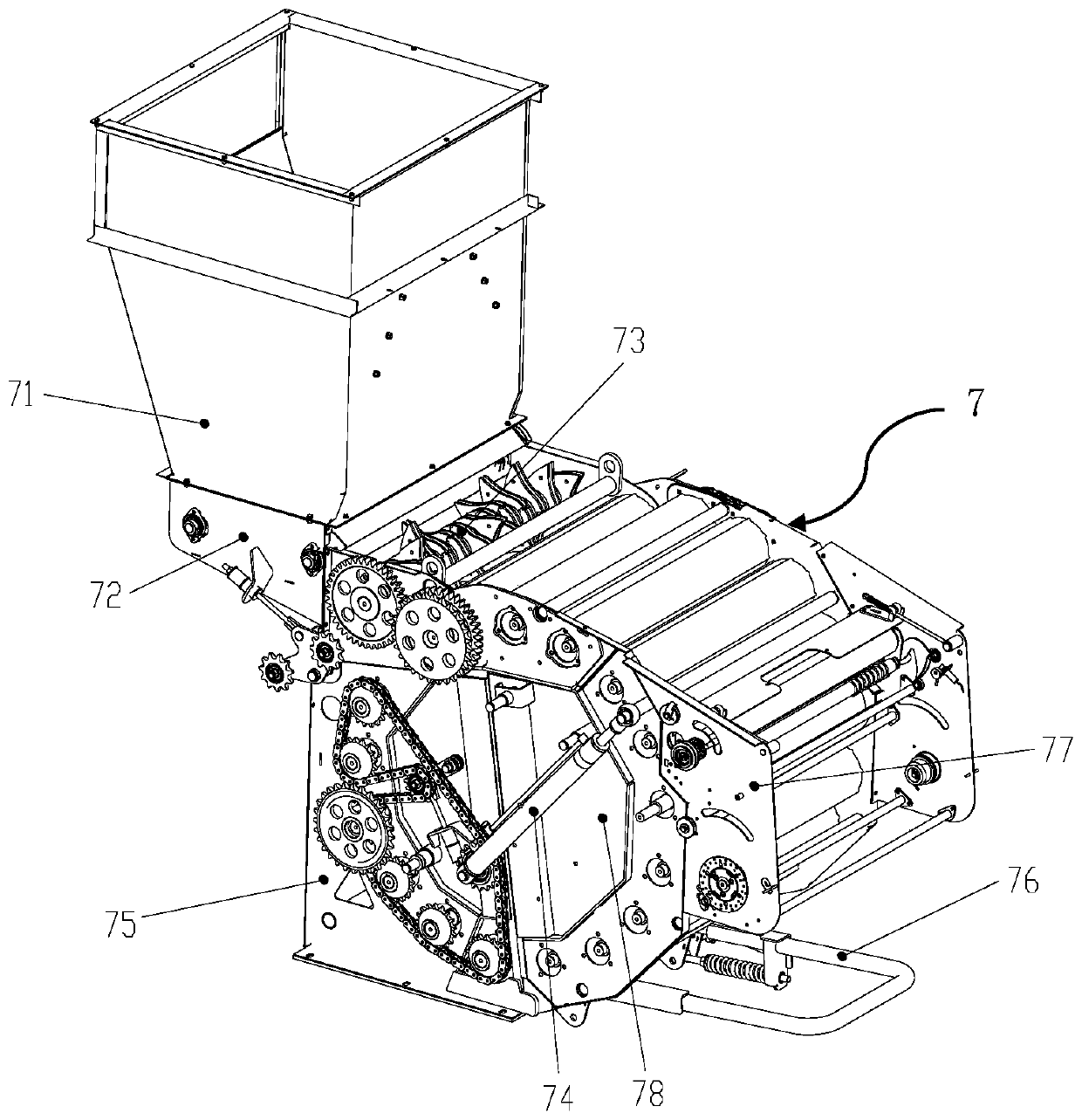

[0078] see figure 1 , figure 1 It is a schematic structural diagram of the whole machine according to an embodiment of the present invention. The self-propelled strapping machine of the present invention comprises a frame 1 and a self-propelled chassis 2 and a power drive 8 mounted on the frame 1, the chassis is located below the frame 1 and is connected to the power The driving device 8 is connected, and also includes a pick-up header 3, a feeding device 4, a crushing device 5, a throwing device 6 and a bundling device 7 installed on the frame 1 and arranged in sequence, and the pick-up header 3 is installed At the front end of the frame 1, the front end of the feeding device 4 is arranged corresponding to the picking header 3 and connected with the picking header 3, and the crushing device 5 is located between the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com