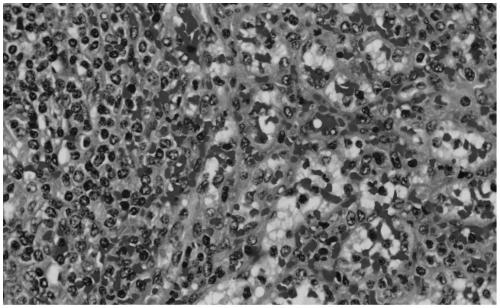

Hematoxylin staining solution oxidation degree monitoring method and a hematoxylin staining solution quality control method

A quality control method and technology of oxidation degree, applied in the field of hematoxylin dyeing solution, can solve the problems such as difficulty in grasping oxidation degree, good and bad film quality, slow coloring, etc., to solve the problem of uncontrollable quality, easy popularization and application, and clear results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

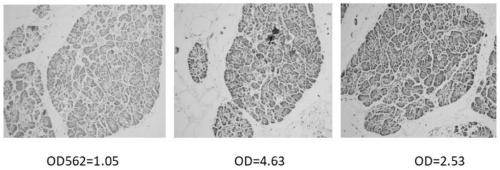

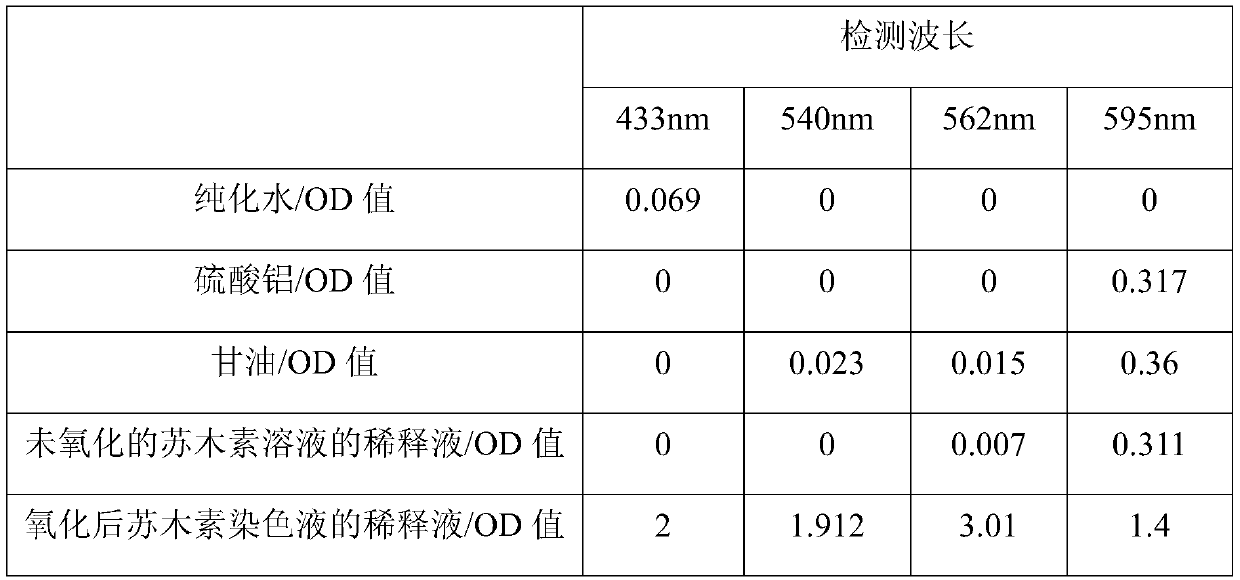

[0057] The method for monitoring the oxidation degree of the hematoxylin staining solution in this embodiment, in this embodiment, 562nm is used as the detection wavelength of the ultraviolet spectrophotometer, and the OD value of the diluent of the hematoxylin staining solution corresponding to the different oxidant dosages shown in Table 1 is detected. , to judge its degree of oxidation, the dilution of the hematoxylin staining solution used in the detection is obtained by diluting the hematoxylin staining solution with 5% aluminum sulfate aqueous solution, and the concentration of hematoxylin in the dilution of the hematoxylin staining solution is 0.125 mg / mL; the steps are as follows:

[0058] (1) Utilize the ultraviolet spectrophotometer to detect the OD value of the dilution solution of the hematoxylin staining solution before oxidation, and record it as OD 0 , OD 0 = 0.23.

[0059] (2) Utilize the ultraviolet spectrophotometer to detect the OD value of the diluted solu...

Embodiment 2

[0065] The method for monitoring the oxidation degree of the hematoxylin staining solution of this embodiment, the present embodiment uses 562nm as the detection wavelength of the ultraviolet spectrophotometer to detect the OD value of the dilution of the hematoxylin staining solution corresponding to different oxidation times as shown in Table 2 , to judge its degree of oxidation, the dilution of the hematoxylin staining solution used in the detection is obtained by diluting the hematoxylin staining solution with 5% aluminum sulfate aqueous solution, and the concentration of hematoxylin in the dilution of the hematoxylin staining solution is 0.125 mg / mL; the steps are as follows:

[0066] (1) Utilize the ultraviolet spectrophotometer to detect the OD value of the dilution solution of the hematoxylin staining solution before oxidation, and record it as OD 0 , OD 0 = 0.23.

[0067] (2) Utilize the ultraviolet spectrophotometer to detect the OD value of the diluted solution of ...

Embodiment 3

[0073] The method for monitoring the oxidation degree of the hematoxylin staining solution of this embodiment, the present embodiment uses 562nm as the detection wavelength of the ultraviolet spectrophotometer, and the diluent of the hematoxylin staining solution used for detection is obtained by diluting the hematoxylin staining solution with 5% aluminum sulfate aqueous solution Yes, the concentration of hematoxylin in the dilution of hematoxylin staining solution is 0.125mg / mL; the steps are as follows:

[0074] (1) Utilize the ultraviolet spectrophotometer to detect the OD value of the dilution solution of the hematoxylin staining solution before oxidation, and record it as OD 0 .

[0075] (2) Utilize the ultraviolet spectrophotometer to detect the OD value of the diluted solution of the hematoxylin staining solution after oxidation, which is recorded as OD t .

[0076] (3) Before and after oxidation, the OD value of the diluent of the hematoxylin staining solution change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com