Distortion generator for testing transient total pressure distortion of axial flow compressor

A generating device and compressor technology, which is applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve problems such as the inability of the distortion plate to rotate, the impact, and the interference of the uniform incoming flow field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

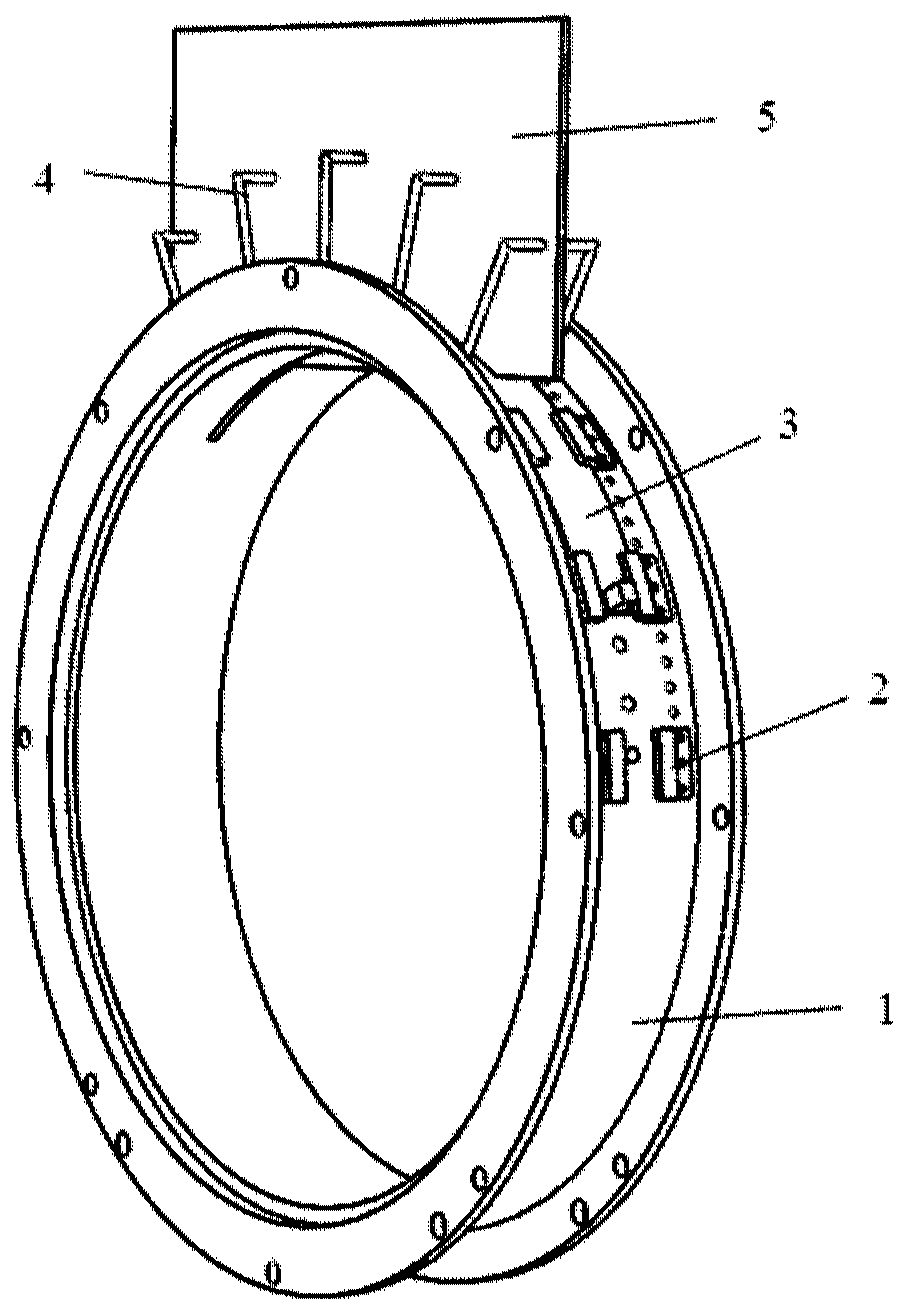

[0057] An embodiment of the present invention provides a distortion generating device for testing the transient total pressure distortion of an axial flow compressor. The structural features of the device include:

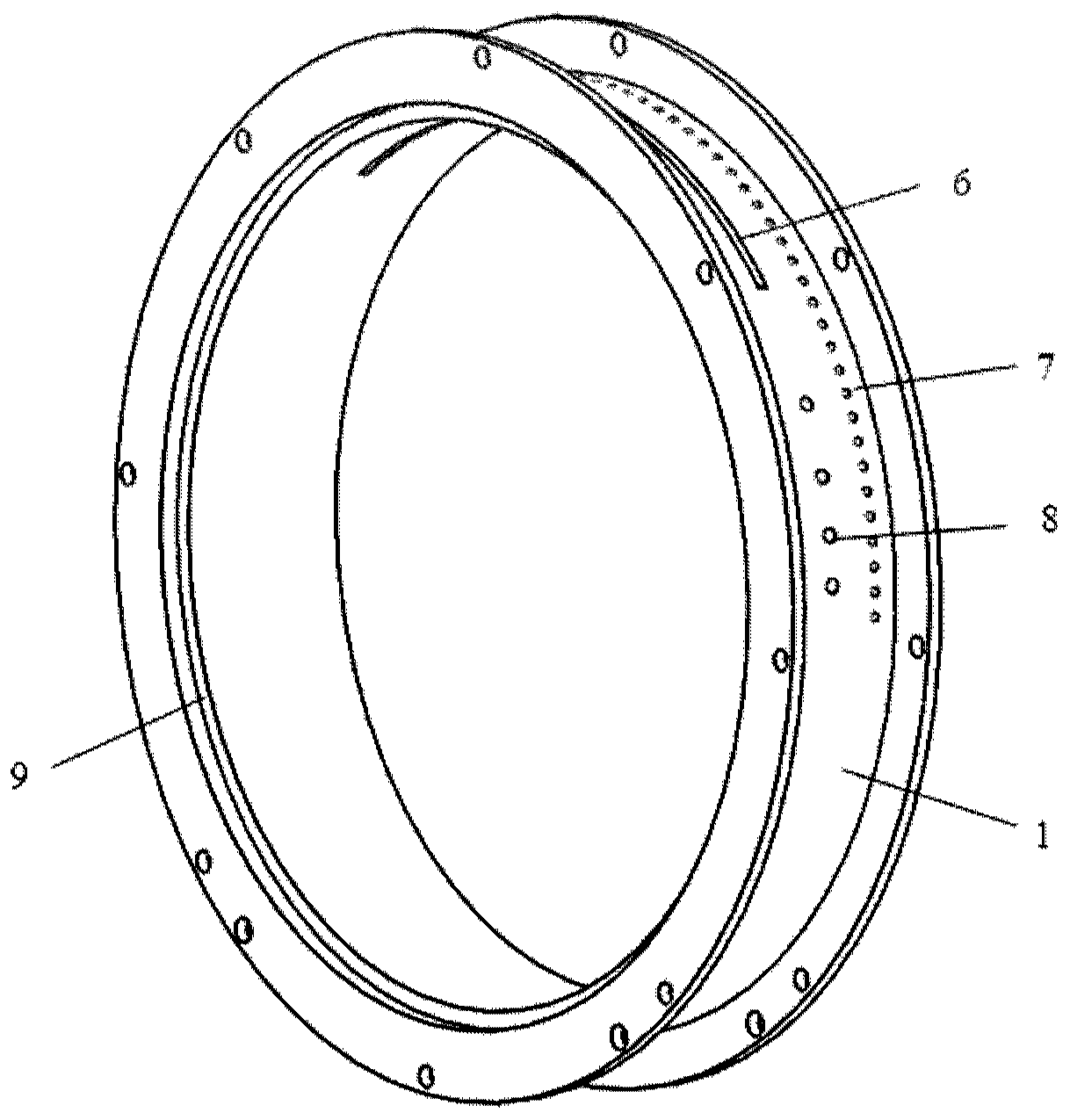

[0058] Slotted casing, including an arc-shaped square slot hole arranged in the circumferential direction, a plurality of threaded blind holes arranged on both sides of the arc-shaped square slot hole and parallel to it, and an arc-shaped square slot arranged symmetrically relative to the right-view datum plane Pin positioning holes at both ends of the hole;

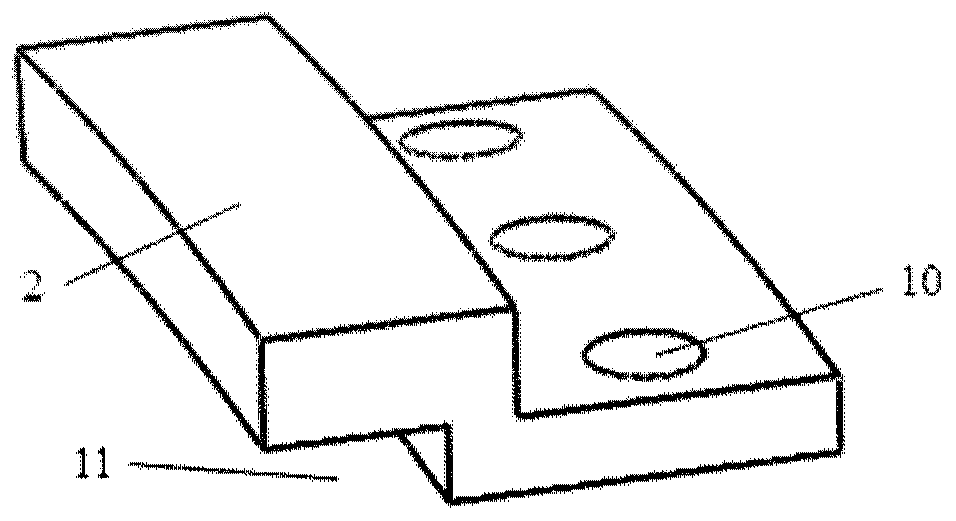

[0059] A plurality of slide rail blocks are discretely fixed on some threaded blind holes on both sides of the arc-shaped square groove;

[0060] Two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com