Near-rail sound absorption and insulation device

A sound insulation and rail suction technology, which is applied in the direction of tracks, roads, buildings, etc., can solve the problems of affecting the line of sight of the train, the sound barrier occupies a large area, and the load requirements are high, achieving the effects of expanding the field of vision, reducing the height, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

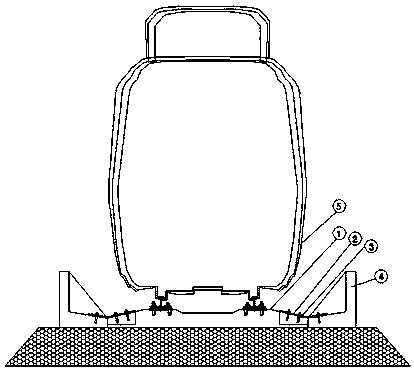

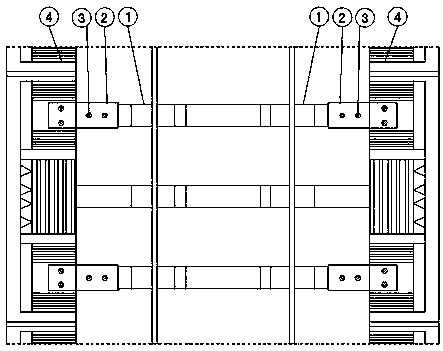

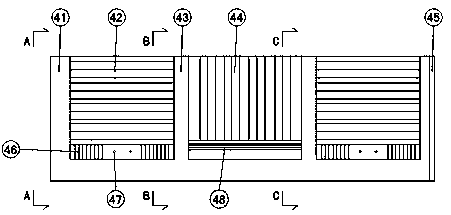

[0020] figure 1 , figure 2 As shown, a near-rail sound absorption device is composed of a connecting piece 2, a mounting bolt 3, and a noise reduction body 4.

[0021] First, level the ground on both sides of the railway sleeper to make the ground even without protrusions or depressions; then the connecting piece 2 is fixed to the sleeper 1 with the mounting bolt 3, and finally the noise reduction body 4 is connected and fixed with the connecting piece 2.

[0022] The connector 2 is made by bending a 10mm thick steel plate, one end is a U-shaped groove connecting end, and the other end is a flat plate, and the U-shaped groove connecting end and the flat plate are both provided with connecting holes with a diameter of 18mm. The U-shaped groove connection end is buckled on the end face of the sleeper and fixed with expansion bolts M16*100. The plate and the noise reduction body of the connector are fixed with bolts M16*50. Play the role of connection and fixation.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com