High-strength and recyclable tobacco strip honeycomb box

A high-strength, sheet-like technology, used in sustainable packaging, sustainable manufacturing/processing, rigid containers, etc., can solve problems such as strength damage, damage, and unevenness, reduce deformation damage, and improve compression resistance. Strength, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

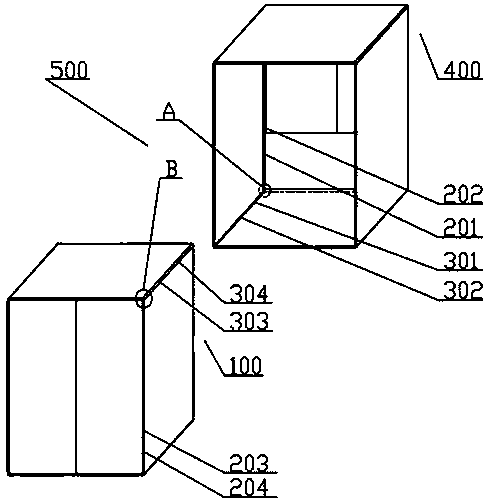

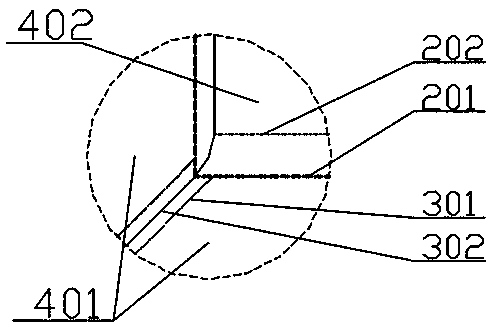

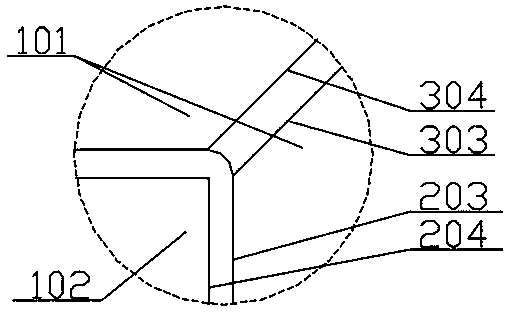

[0041] refer to Figure 1~8 , a high-strength recyclable cigarette honeycomb box, including an inner box 100 and an outer box 400, the inner box 100 and the outer box 400 are composed of side walls and flaps, and the side walls are made of bent 90° The two side panels are spliced together, and the folding structure between the side panels and the flap consists of two indentations on the inner side of the inner box 100 / outer box 400, and two indentations on the inner side of the inner box 100 / outer box 400. It is composed of one valgus indentation 203 on the outer side of the fold, and the valgus indentation and valgus indentation 203 are distributed alternately; One indentation 302 and two indentations located on the outer side of the inner box 100 / outer box 400, and the indentations 302 and outer indentations are alternately distributed.

[0042] Both the inner box 100 and the outer box 400 are square structural boxes with an opening on one side, the inner box 100 is set i...

Embodiment 2

[0054] Compared with Example 1, a high-strength recyclable sheet tobacco honeycomb box of this example has the following differences:

[0055] refer to Figure 9~12 , the number of inversion indentations is 3, including the first inversion indentation 201, the second inversion indentation 202 and the third inversion indentation 205, the first inversion indentation 201 is located in the second inversion indentation Between the indentation 202 and the third indentation 205, the depth of the first indentation 201 is 2 / 3 of the thickness of the honeycomb cardboard used for the honeycomb sheet smoke box, that is, 6.7 mm, and the depth of the second indentation 202 is It is 1 / 3 of the thickness of the honeycomb cardboard for the honeycomb sheet cigarette box, that is, 3.3.mm, and the depth of the third indentation 205 is 1 / 2 of the thickness of the honeycomb paperboard for the honeycomb sheet cigarette box, that is, 5mm. The distance between the indentations is 1.1 times the thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com