Industrial waste gas purifier

A technology of industrial waste gas and purifier, applied in the direction of chemical instruments and methods, gas treatment, combined devices, etc., can solve the problems of reducing the overall purification efficiency, affecting the rate of malodorous gas entering the photolysis chamber, and high labor intensity. Convenient centralized disassembly or cleaning, reducing the probability of dust passing through, and the effect of high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

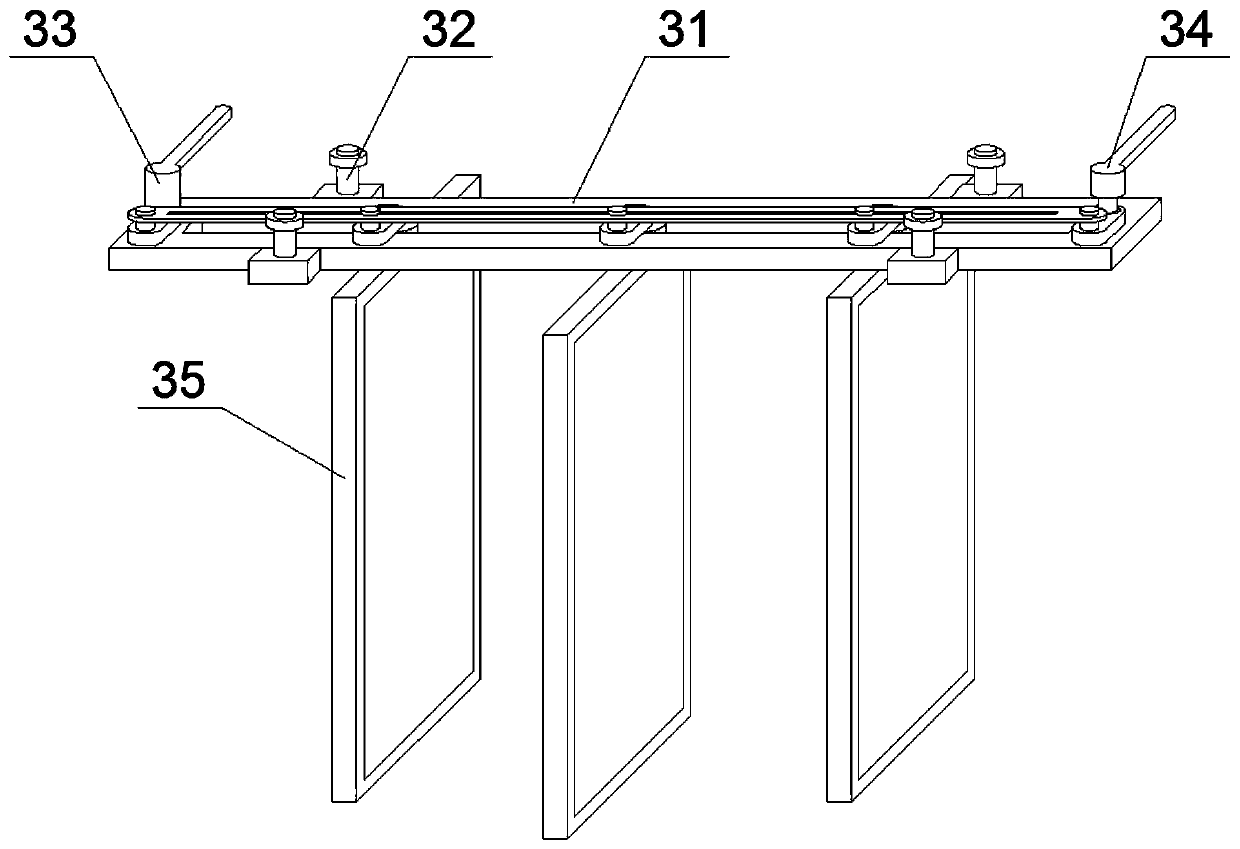

[0022] Such as Figure 1 to Figure 5 As shown, the industrial waste gas purifier provided in this embodiment includes a dust removal chamber 1 and a UV photolysis chamber 2 that are connected to each other. 4. One side of the UV photolysis chamber 2 is provided with an air outlet. This application replaces the current form of installing a fine filter screen at the waste gas inlet 4 and the air outlet. The dustproof assembly 3, the dustproof assembly 3 includes a fixed base 31 and a plurality of dust shields 35 arranged side by side and parallel to each other, the fixed base 31 includes a seat plate 311 and two fixing pieces respectively fixed on both sides of the seat plate 311 32. Each fixing piece 32 is connected to the top wall of the dust removal chamber 1. The fixing piece 32 includes a seat body 321, a screw rod 322 and a nut 323. The seat body 321 is fixed on the side wall of the seat plate 311, and the screw rod 322 is vertically fixed on the seat plate. body 321, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com