Water-permeable paved anti-sliding road surface

A permeable pavement and anti-slip technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of the impact of road surface anti-slip ability, small contact area, single effect, etc., to solve urban waterlogging problems, chemical properties Outstanding effect of stability and anti-skid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

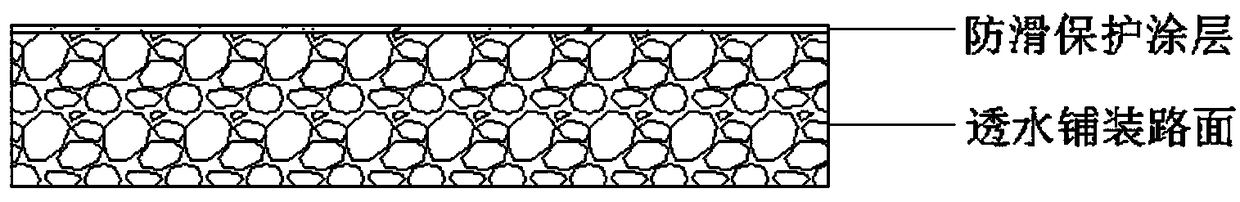

[0014] A permeable pavement anti-slip pavement, comprising an anti-slip layer and a permeable pavement sequentially arranged from top to bottom, the anti-slip layer includes a protective agent and quartz sand, wherein the protective agent includes the following raw materials in mass fraction: acrylic resin 70%, film-forming 2% agent, 2% coagulant aid, 12% polyurethane, 2% propylene glycol, 10% pigment, 1.5% polyurethane curing agent, and 0.5% defoamer. The thickness of the anti-skid layer is 3mm. The amount of protective agent added is 0.55kg / m 2 , the amount of quartz sand added is 5% of the amount of protective agent added, the particle size of the quartz sand in the anti-skid layer is 70 mesh, and the permeable pavement has a multi-void structure. The paving method of the permeable pavement is as follows: after the permeable pavement is poured and compacted, the surface is coated with a protective agent with a thickness of 0.2mm, and a layer of quartz sand is evenly spraye...

Embodiment 2

[0016] A permeable pavement anti-slip pavement, comprising an anti-slip layer and a permeable pavement arranged in sequence from top to bottom, the anti-slip layer includes a protective agent and quartz sand, wherein the protective agent includes the following raw materials in mass fraction: acrylic resin 66%, film-forming 3% agent, 4% coagulant aid, 15% polyurethane, 2% propylene glycol, 7% pigment, 2% polyurethane curing agent, and 1% defoamer. The thickness of the anti-skid layer is 2mm. The amount of protective agent added is 0.58kg / m 2 , the amount of quartz sand added is 5% of the amount of protective agent added, the particle size of the quartz sand in the anti-skid layer is 80 mesh, and the permeable pavement has a multi-void structure. The paving method of the permeable pavement is as follows: after the permeable pavement is poured and compacted, the surface is coated with a protective agent with a thickness of 0.2mm, and a layer of quartz sand is evenly sprayed from...

Embodiment 3

[0018] A permeable pavement anti-slip pavement, comprising an anti-slip layer and a permeable pavement arranged in sequence from top to bottom, the anti-slip layer includes a protective agent and quartz sand, wherein the protective agent includes the following raw materials in mass fraction: acrylic resin 66%, film-forming Agent 4%, coagulant 2%, polyurethane 17%, propylene glycol 1%, pigment 8%, polyurethane curing agent 1.5%, defoamer 0.5%. The thickness of the anti-skid layer is 4mm. The amount of protective agent added is 0.60kg / m 2 , the amount of quartz sand added is 5% of the amount of protective agent added, the particle size of the quartz sand in the anti-skid layer is 90 mesh, and the permeable pavement has a multi-void structure. The paving method of the permeable pavement is as follows: after the permeable pavement is poured and compacted, the surface is coated with a protective agent with a thickness of 0.2mm, and a layer of quartz sand is evenly sprayed from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com