Screw assembly for bone fixation and bone fixing device

A technology for bone fixation and screw assembly, applied in the field of medical devices, can solve the problems of easy deformation and fracture, insufficient mechanical properties of implants, etc., and achieve the effects of stable mechanical properties, good bone healing and remodeling effects, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

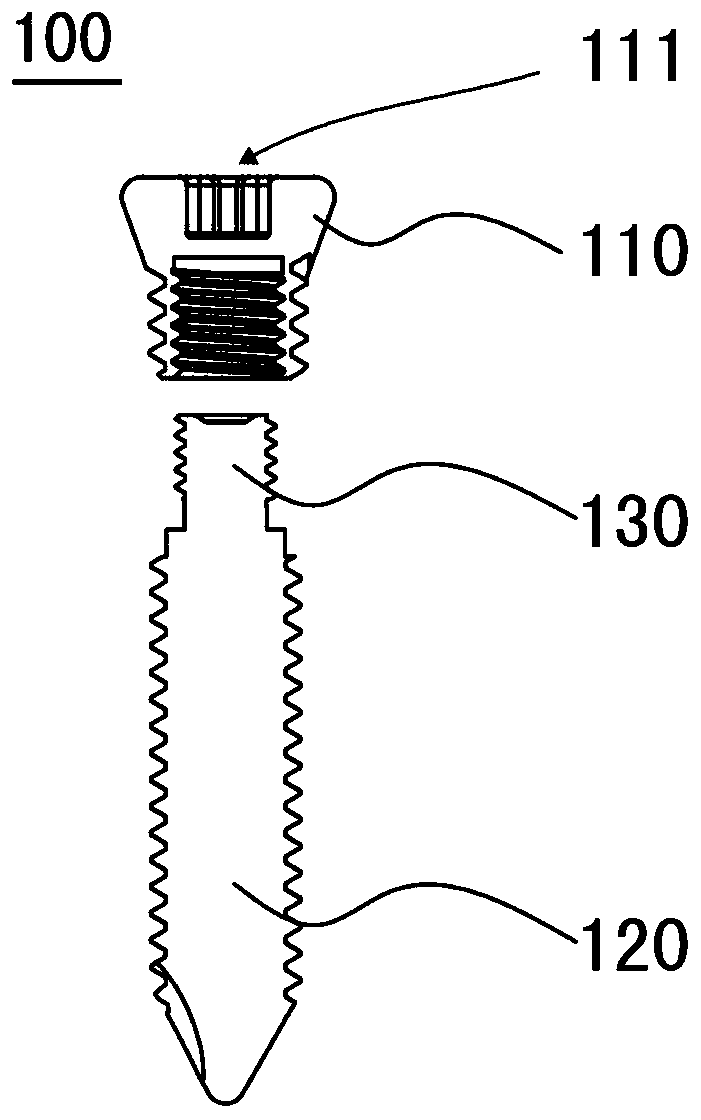

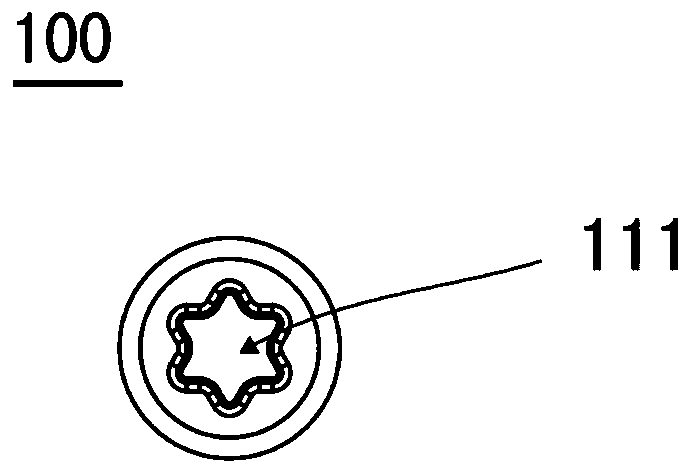

[0046] see figure 1 As shown, the present embodiment provides a screw assembly 100 for bone fixation. The screw assembly 100 for bone fixation includes a non-degradable nut 110 and a degradable and absorbable screw body 120 , the nut 110 is detachably connected to one end of the screw body 120 , and the outer peripheral surface of the screw body 120 has external threads. The nut 110 can be made of non-degradable materials with strong mechanical properties such as stainless steel and titanium alloy.

[0047] The screw assembly 100 for bone fixation also includes a connector 130 . The nut 110 is detachably connected to the screw body 120 through a connecting piece 130 .

[0048] see image 3 As shown, the connecting piece 130 is integrally connected with the nut 110 , the connecting piece 130 has an external thread, the end surface of the screw body 120 mated with the nut 110 has a matching groove with an internal thread, and the connecting piece 130 is screwed into the match...

Embodiment 2

[0059] This embodiment provides a bone fixation device 10 .

[0060] A bone fixation device 10 includes a bone plate 200 and the screw assembly 100 for bone fixation described in Embodiment 1. see Figure 4 As shown, the bone plate 200 is penetrated with several fixing through holes 210 along its thickness direction, and the screw body 120 is used to cooperate with the fixing through holes 210 . After the screw main body 120 of the screw assembly 100 passes through the fixing through hole 210 and cooperates with it, the end of the screw main body 120 away from the nut 110 protrudes from the bone plate 200, so that the screw main body 120 can be inserted into the bone 20 after passing through the bone plate 200 . Preferably, the length of the screw body 120 is greater than the thickness of the bone plate 200 .

[0061] Preferably, the inner diameter of the fixing through hole 210 is smaller than the maximum outer diameter of the head of the nut 110 .

[0062] The bone fixat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com