Communication electronic internal element protection device with auxiliary heat dissipation structure

A technology for internal components and auxiliary heat dissipation. It is applied in the direction of electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc. It can solve the problems of easy accumulation of heat and difficult dissipation, influence and damage of electronic equipment, and achieve high efficiency and uniformity. Effect of heat dissipation, reduction of heat accumulation, and improvement of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

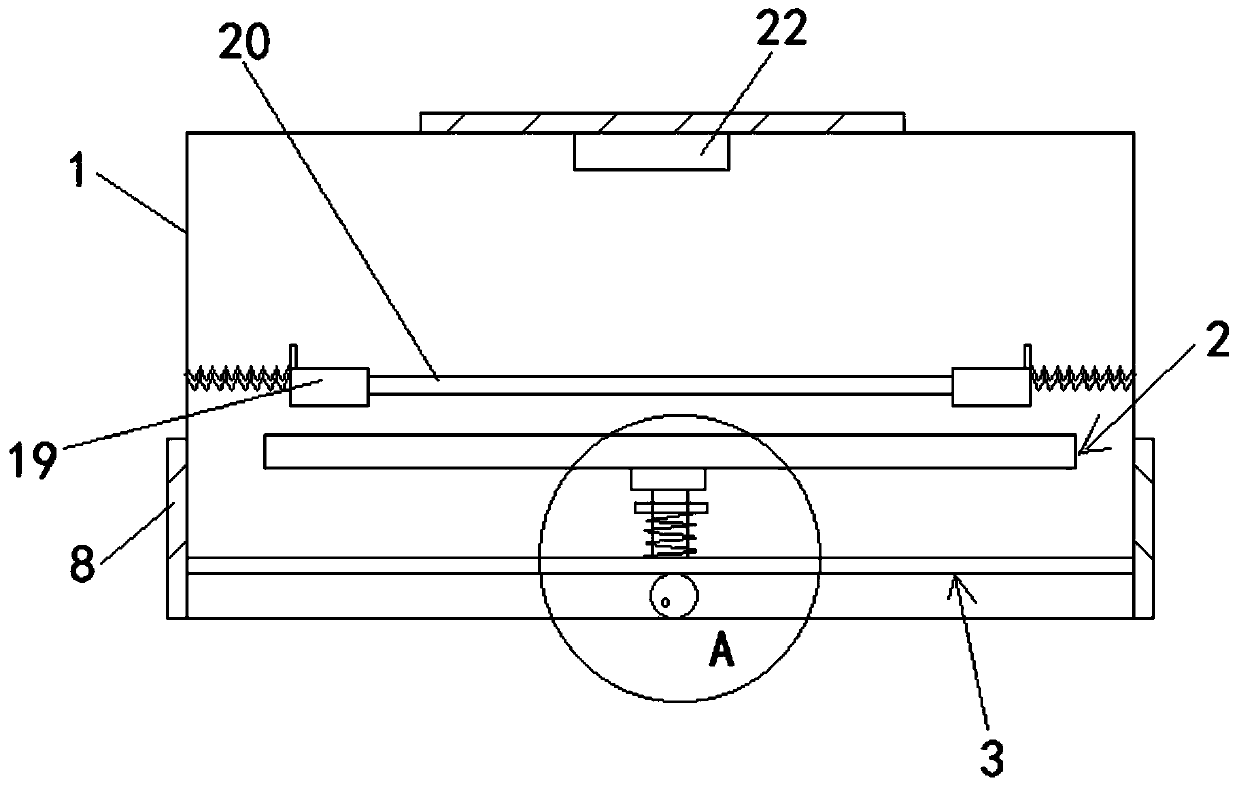

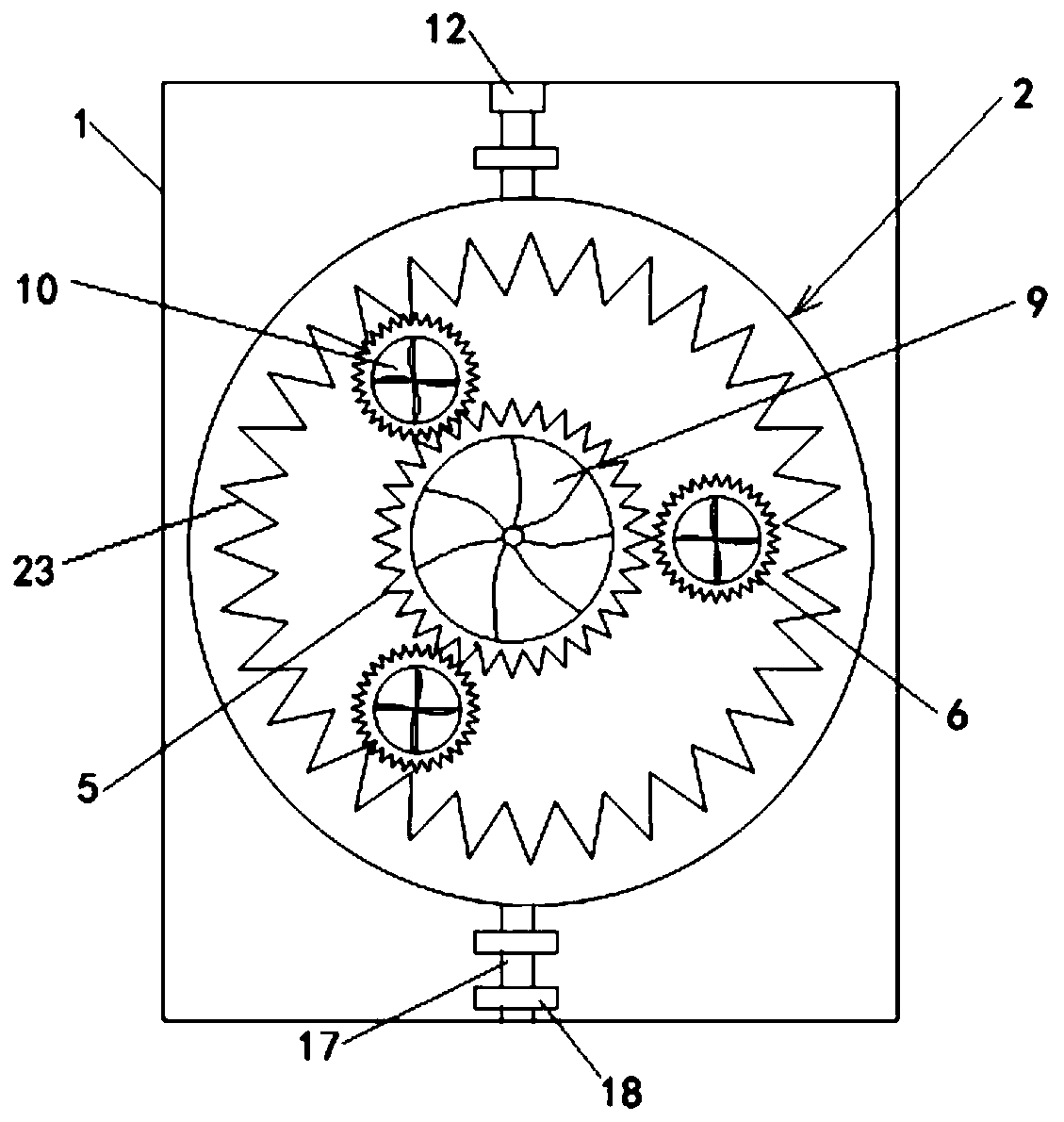

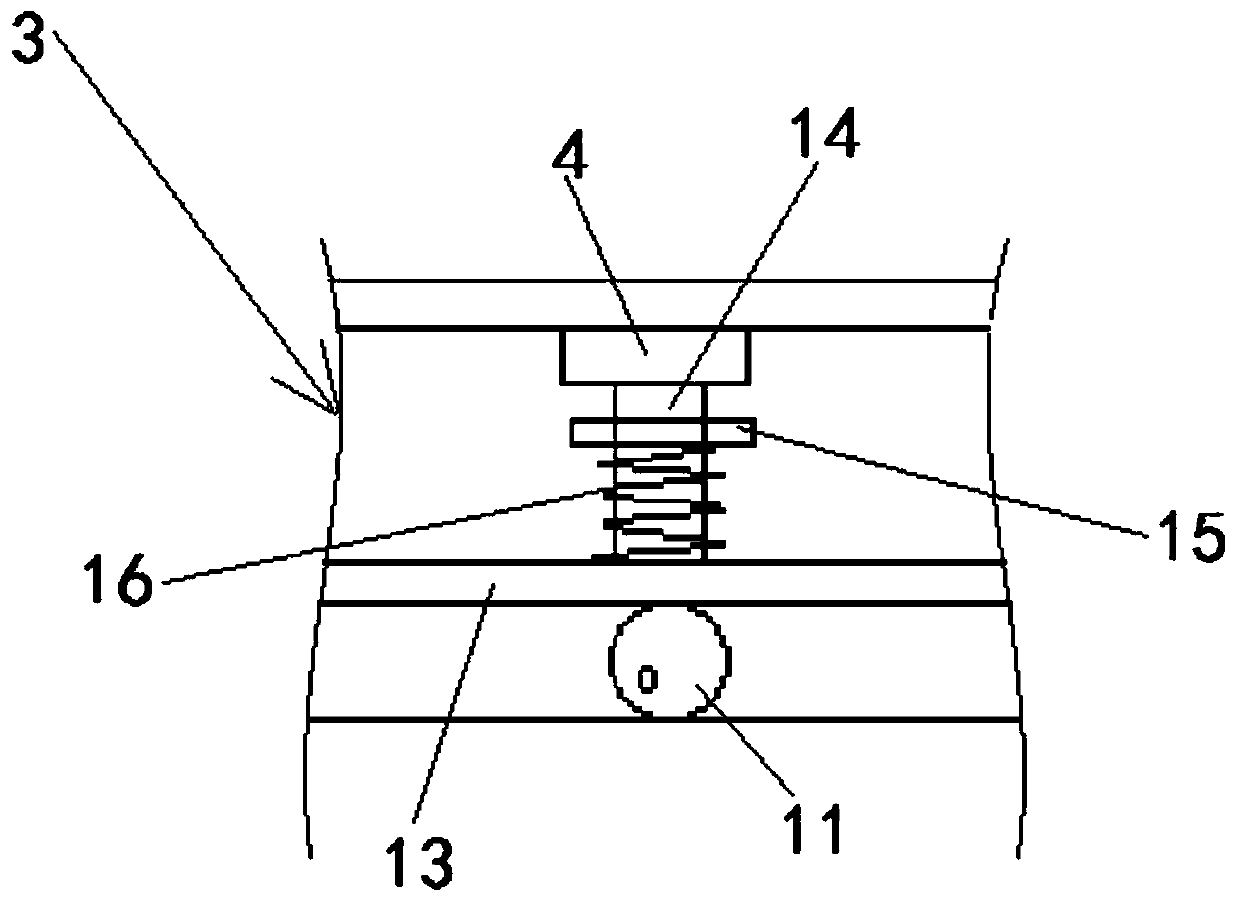

[0028] Below in conjunction with accompanying drawing in the embodiment of the present invention, for preferred embodiment and accompanying drawing Figure 1-4 With detailed instructions.

[0029] A protection device for internal components of communication electronics with an auxiliary heat dissipation structure, such as figure 1 As shown, it includes a heat dissipation mechanism 2 and a moving mechanism 3, the moving mechanism 3 is used for the reciprocating movement of the heat dissipation mechanism 2 up and down, the heat dissipation mechanism 2 is arranged on the top of the moving mechanism 3, and is jointly arranged on the protective shell 1 Inside, the protective case 1 is composed of a top case and a bottom case that are interlocked and detachably connected. The heat dissipation mechanism 2 is used to efficiently dissipate heat for the internal components of the communication electronics. The moving mechanism 3 is used to make the heat dissipation mechanism 2 reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com