Optical lens, manufacturing method of optical lens and optical imaging device

A technology for optical lenses and manufacturing methods, applied in the field of optical lenses and optical imaging devices, capable of solving problems such as poor anti-reflection effects of optical lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

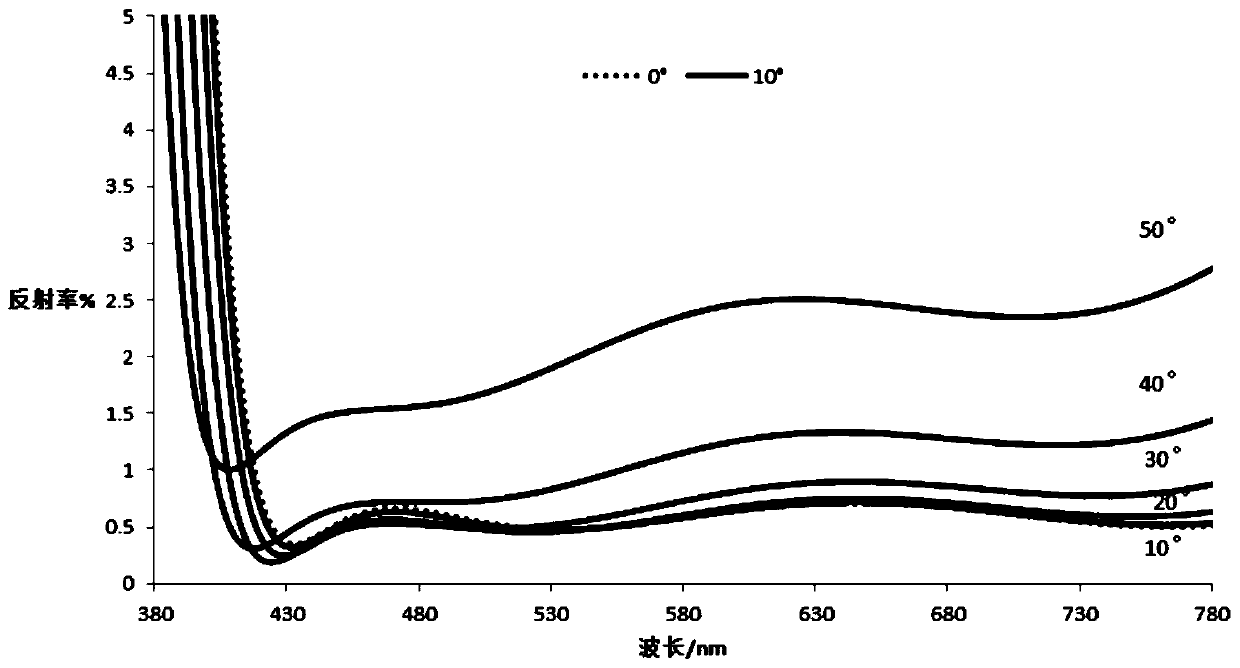

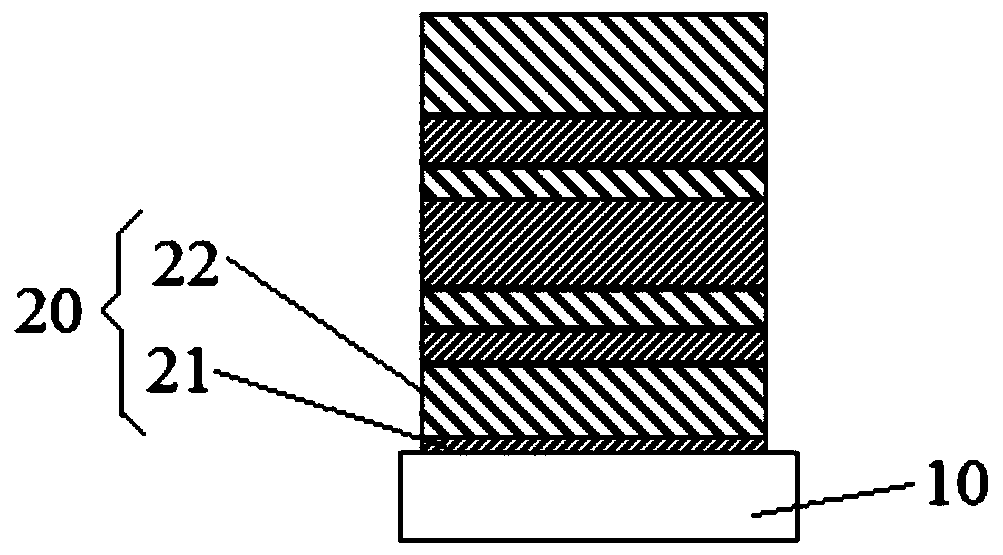

[0056] exist image 3 In the specific embodiment shown, the optical lens includes a lens base 10 and an anti-reflection film system 20, and the structure of the optical lens is: Sub / (HL)^m / Air, where m=4, that is, starting from the lens base 10, The first layer is a high-refractive-index film layer 21, the second layer is a low-refractive-index film layer 22, the third layer is a high-refractive-index film layer 21, and the fourth layer is a low-refractive index film layer 22, repeating this four times. In this embodiment, the high refractive index film layer 21 is made of Ti 3 o 5 composition, and the high refractive index film layer 21 is 2.26, and the material of the low refractive index film layer 22 is Al 2 o 3 and SiO 2 mixture, and the low refractive index film layer 22 has a refractive index of 1.46. In this embodiment, the thickness of each film layer from the direction close to the lens substrate 10 to away from the lens substrate 10 is: 10.28nm, 57.22nm, 12.75n...

Embodiment 2

[0064] The difference from the first embodiment is that the specific structure of the anti-reflection film system 20 is different.

[0065]In this embodiment, the optical lens includes a lens base 10 and an anti-reflection film system 20, and the structure of the optical lens is: Sub / L(HL)^m / Air, where m=4, that is, starting from the lens base 10, the first One layer is a low refractive index film layer 22, the second layer is a high refractive index film layer 21, the third layer is a low refractive index film layer 22, the fourth layer is a high refractive index film layer 21, and the fifth layer is a low refractive index film layer. Film layer 22, the sixth layer is a high refractive index film layer 21, the seventh layer is a low refractive index film layer 22, the eighth layer is a high refractive index film layer 21, and the ninth layer is a low refractive index film layer 22, to ensure The low refractive index film layer 22 is in contact with air. In this embodiment, t...

Embodiment 3

[0068] The difference from the first embodiment is that the material of the anti-reflection film system 20 is different.

[0069] In this embodiment, the optical lens includes a lens base 10 and an anti-reflection film system 20, and the structure of the optical lens is: Sub / (HL)^m / Air, where m=4, that is, starting from the lens base 10, the first The first layer is a high refractive index film layer 21, the second layer is a low refractive index film layer 22, the third layer is a high refractive index film layer 21, and the fourth layer is a low refractive index film layer 22, so repeat four times. In this embodiment, the high refractive index film layer 21 is made of Ta 2 o 5 composition, and the high refractive index film layer 21 is 2.22, and the material of the low refractive index film layer 22 is SiO 2 , and the low refractive index film layer 22 has a refractive index of 1.48. In this embodiment, the thicknesses of the film layers from the direction close to the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com