Graphite lubricating device of rotary kiln

A graphite lubrication and rotary kiln technology, applied in the field of rotary kiln, can solve the problems of changing pressing force, difficult maintenance, complicated installation, etc., and achieve the effects of easy replacement, good lubrication characteristics, and improved post-maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

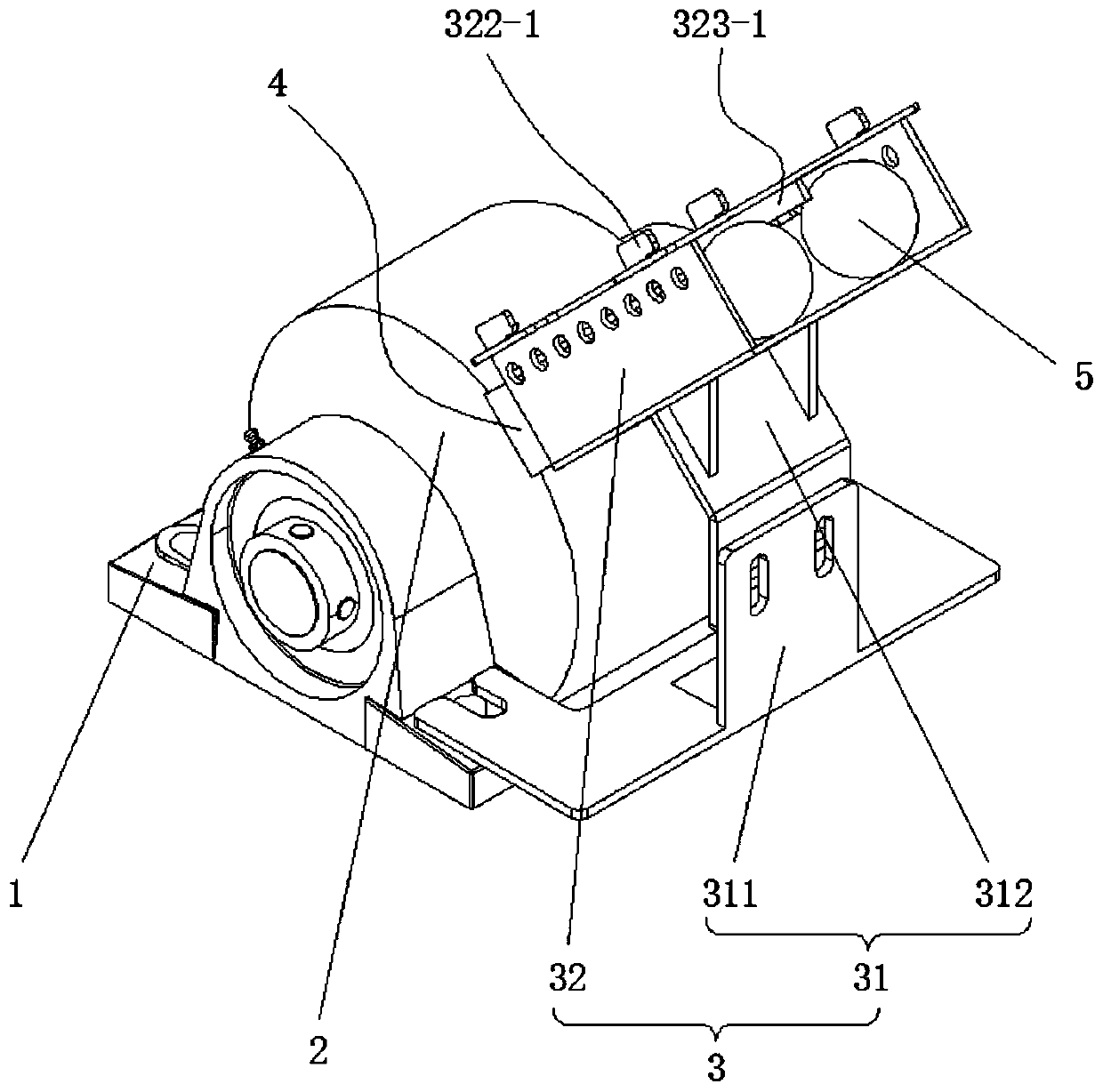

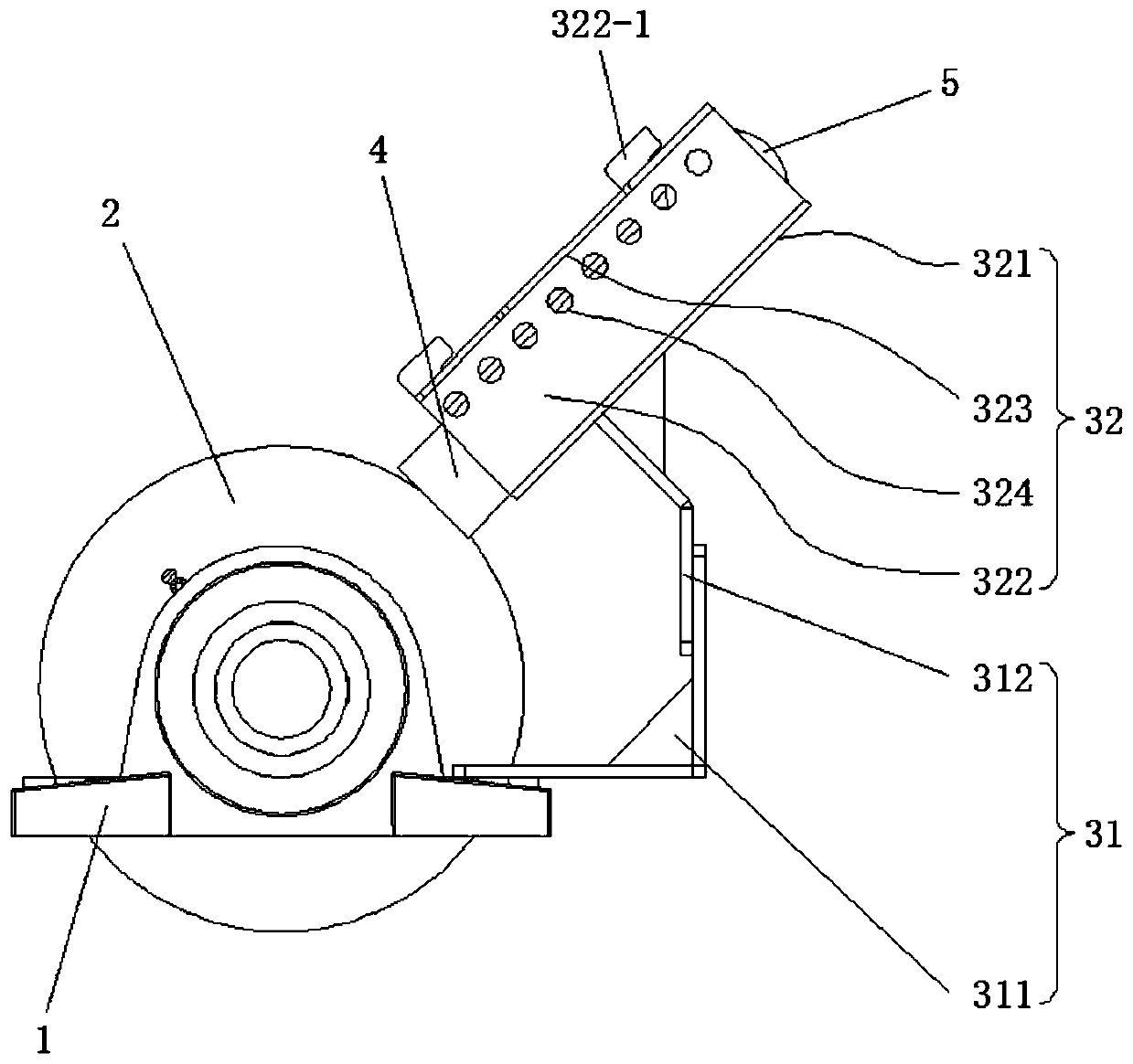

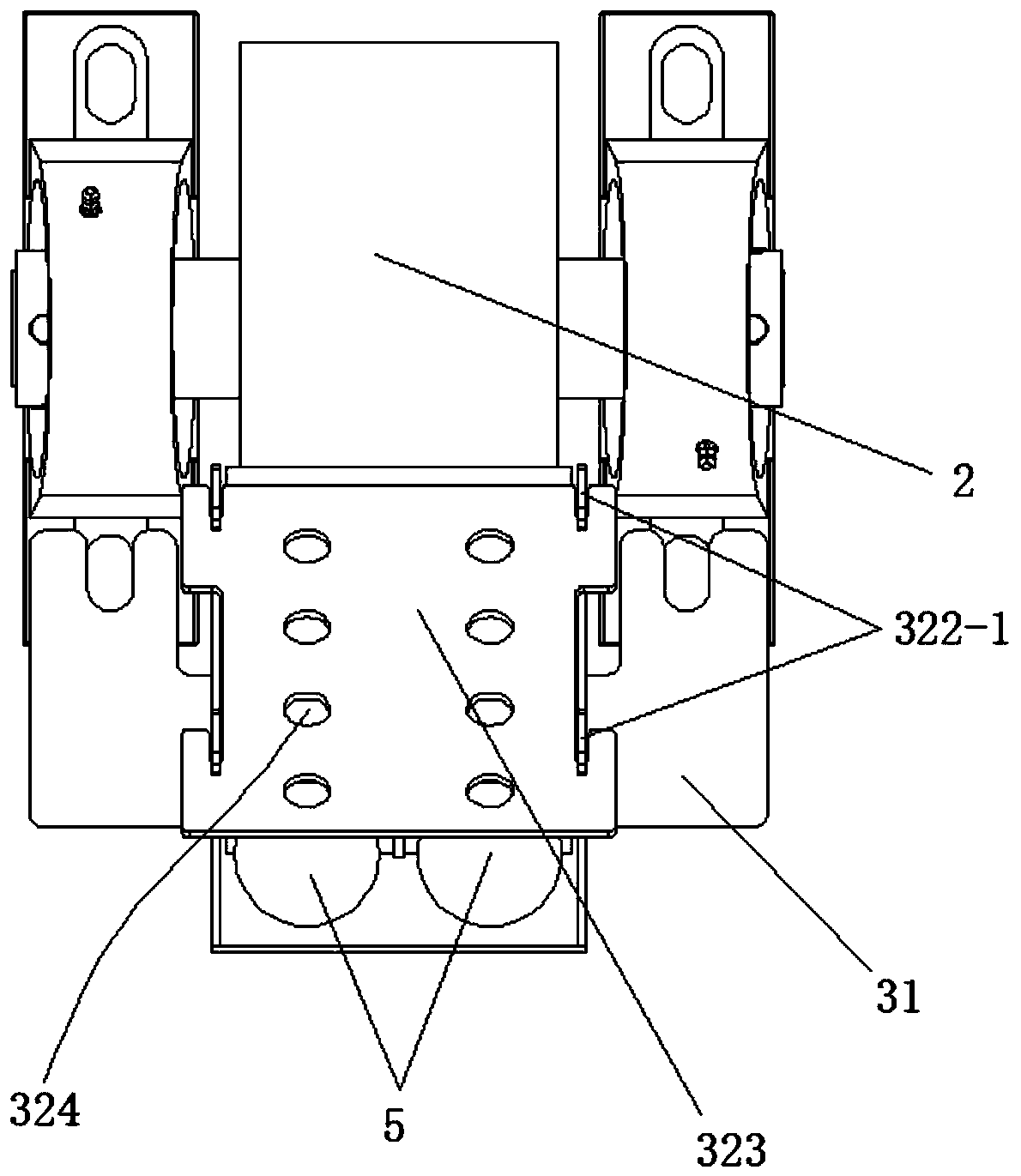

[0026] See Figure 1 to Figure 4 , the present invention has a supporting wheel seat 1 and a supporting wheel 2; the supporting wheel seat 1 is symmetrically provided with a bearing seat, and a bearing is arranged in the bearing seat, and the two ends of the supporting wheel 2 are respectively connected with corresponding bearings, and the supporting wheel 2 It is arranged on the supporting wheel base 1 by bearing rotation; the mounting bracket 3 is fixedly arranged on the supporting wheel base 1; Fixedly be provided with box body 32; Described box body 32 comprises bottom plate 321, is arranged on the side plate 322 of bottom plate 321 both sides, and is connected with side plate 322 and is oppositely arranged with the cover plate 323 of bottom plate 321; Bottom plate 321, side plate 322 and the cover plate 323 to form a through cavity for sliding the graphite block 4 inside; the through cavity of the box body 32 is inclined downward; the support part 31 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com