Photothermal stimulation intelligent response actuator film, preparation method of film and application of film

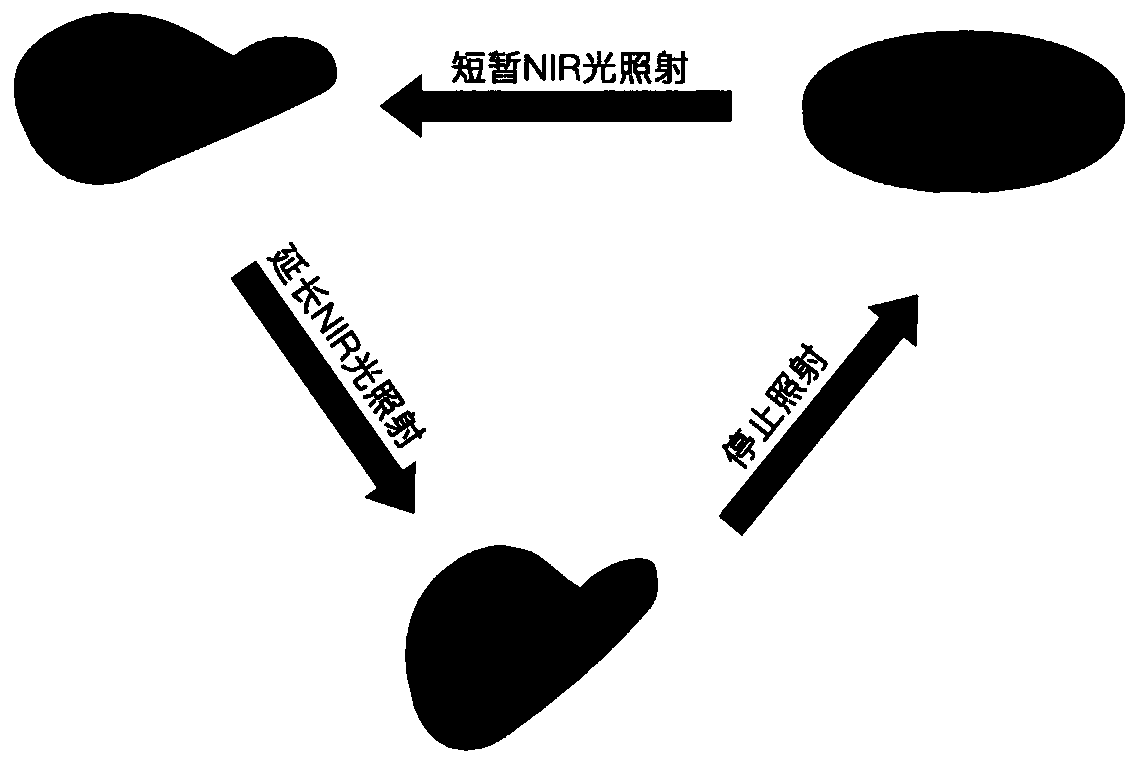

A photothermal response, actuator technology, applied in mechanical equipment, machines/engines, mechanisms that generate mechanical power, etc., can solve problems that need to be further improved, and achieve the effects of high production efficiency, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The preparation method of the photothermal stimulation intelligent response actuator film of this embodiment includes the following steps:

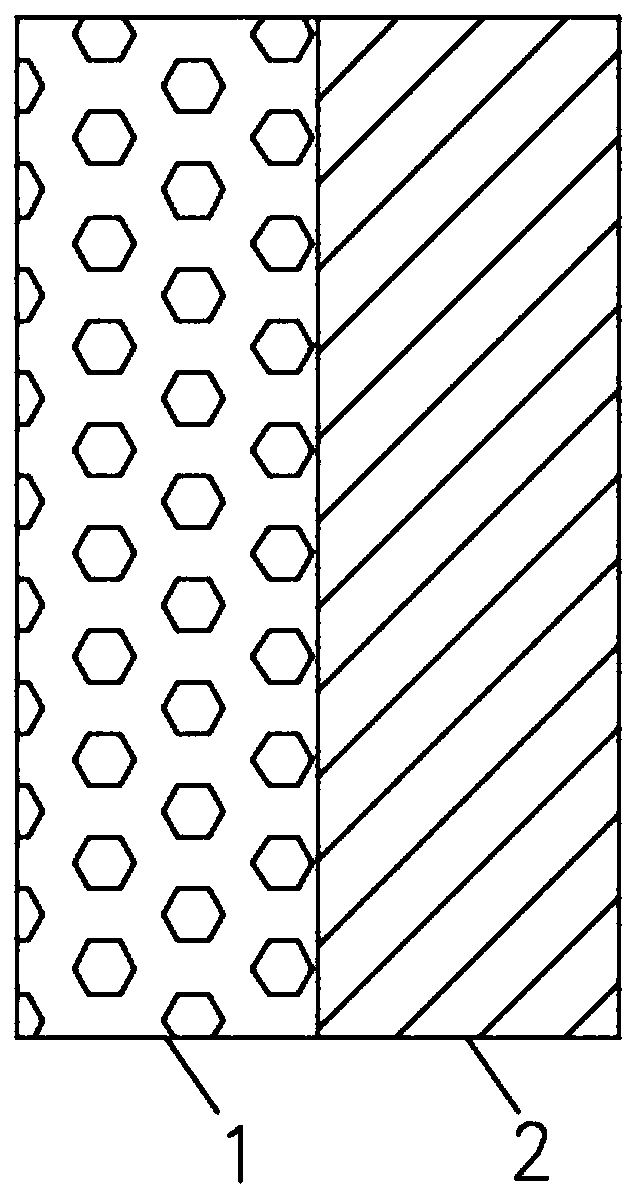

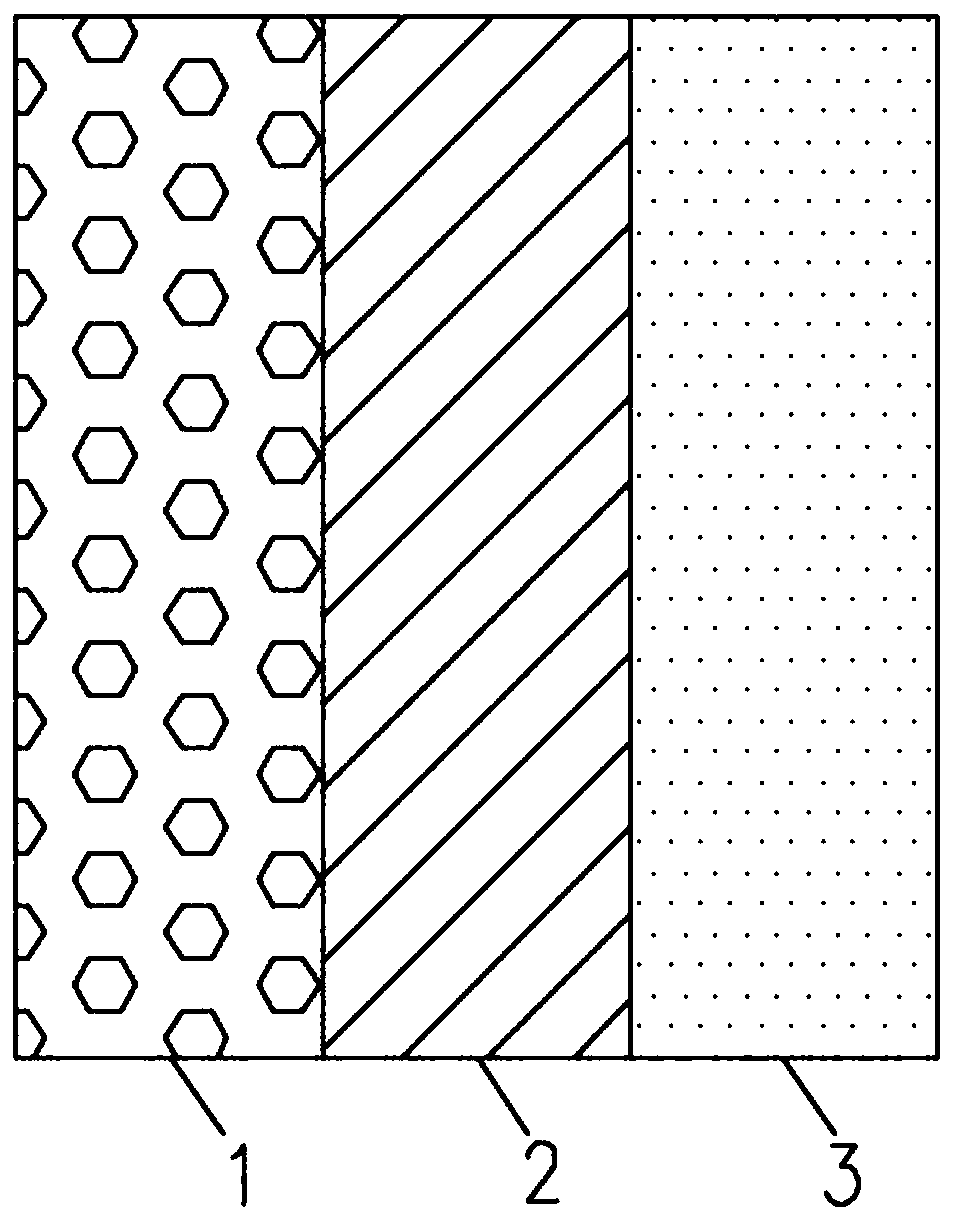

[0068] Step 1: Take 3mg of graphene oxide and disperse it in 1ml of deionized water. Use a rotating speed of 90 rpm and magnetic stirring for 72 hours. After stirring, use a flow rate of 0.5 ml / s and suction filtration for 20 seconds to form a film. The thickness is 0.02mm carbon nano material film layer 2.

[0069] Step 2: Take 5mg of poly-N-isopropylacrylamide (weight average molecular weight of 3,000) and 5mg of graphene oxide, dissolve in 10ml of deionized water, use a rotational speed of 90 revolutions / min, magnetically stir for 72 hours, and stir evenly to obtain Mix solution A. Among them, the particle size of graphene oxide is 0.2 μm-10 μm.

[0070] Step 3: Coat the mixed solution A obtained in step 2 on the carbon nano material film layer 2 obtained in step 1, using a flow rate of 0.5 ml / s, suction filtration for 20 seconds, an...

Embodiment 2

[0080] The preparation method of the photothermal stimulation intelligent response actuator film of this embodiment includes the following steps:

[0081] Step 1: Take 6mg of single-walled carbon nanotubes and disperse them in 3ml of N,N-dimethylformamide, using a rotating speed of 120 revolutions / min, magnetic stirring for 48 hours, after stirring evenly, drying at 55°C for 2 hours to form a film , A carbon nano material film layer 2 with a thickness of 0.03 mm is obtained. Among them, the particle size of single-walled carbon nanotubes is 1nm-2nm.

[0082] Step 2: Take 25mg of poly-N-isopropylacrylamide (weight average molecular weight of 70,000) and 25mg of graphene oxide, dissolve in 10ml of deionized water, use a rotating speed of 120 rpm, magnetic stirring for 48 hours, after stirring uniformly, obtain Mix solution A.

[0083] Step 3: Coat the mixed solution A obtained in step 2 on the carbon nano material film layer 2 obtained in step 1, and bake at 55°C for 2 hours to form ...

Embodiment 3

[0093] The preparation method of the photothermal stimulation intelligent response actuator film of this embodiment includes the following steps:

[0094] Step 1: Take 8mg of multi-walled carbon nanotubes, disperse them in 5ml of ethanol, use a rotating speed of 150 rpm, magnetic stirring for 24 hours, after stirring, air dry at 20°C for 10 hours, and form a film to obtain a carbon nano material with a thickness of 0.02 mm 膜层2。 Film layer 2. Among them, the particle size of the multi-walled carbon nanotubes is 20 nm-40 nm.

[0095] Step 2: Take 35mg of poly-N-isopropylacrylamide (weight-average molecular weight of 200,000) and 15mg of multi-walled carbon nanotubes, and dissolve in 5ml of N,N-dimethylformamide at a speed of 150 revolutions / min , Magnetic stirring for 24h, after stirring evenly, a mixed solution A is obtained.

[0096] Step 3: Coat the mixed solution A obtained in step 2 on the carbon nano material film layer 2 obtained in step 1, air dry at 20°C for 10 hours, and for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com