Equal-load replacement light soil side wide roadbed structure, and design and construction methods thereof

A light soil and subgrade technology, applied in the field of geotechnical engineering, can solve problems such as reducing additional stress, affecting ride comfort and comfort, and reducing eccentric force, so as to reduce vertical or lateral deformation and reduce ecological environment damage , Reduce the effect of additional stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

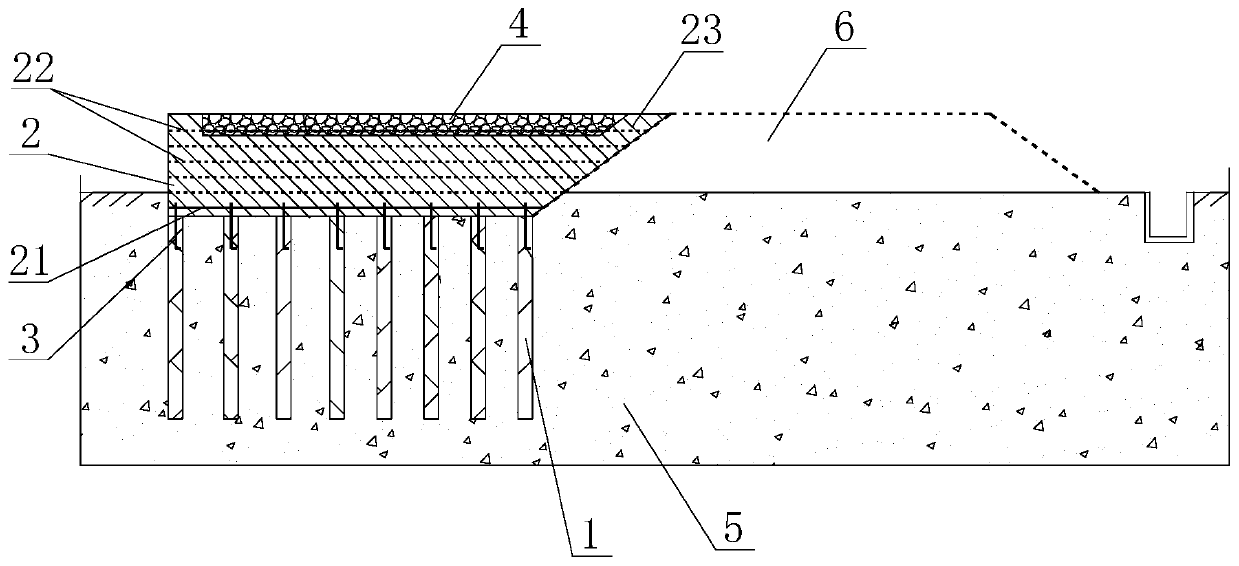

[0060] Such as Figure 1-2 As shown, a kind of equal-load replacement lightweight soil side wide subgrade structure described in this embodiment, refer to figure 1 , the present invention replaces the wide subgrade structure of lightweight soil side with equal load, including composite lightweight piles 1, which are arranged vertically and horizontally at intervals in the foundation 5 adjacent to the existing ballastless track subgrade 6; Pile 1 pile top; connecting steel bars 3, one end of which is anchored into the pile body, and one end is fixedly connected with the light soil tank 2; the soil filler layer 4 is filled in the light soil tank 2.

[0061] In the above scenario:

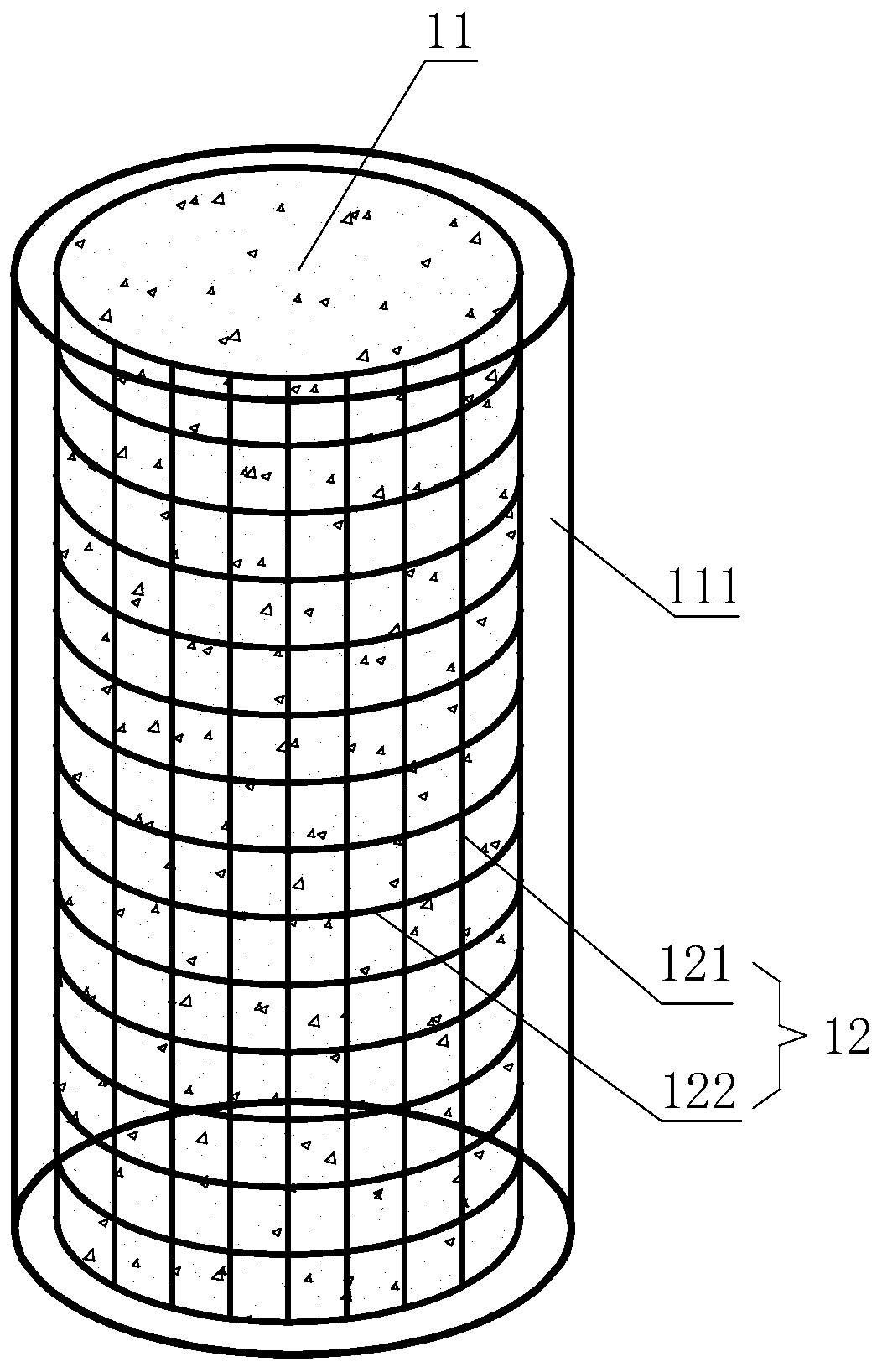

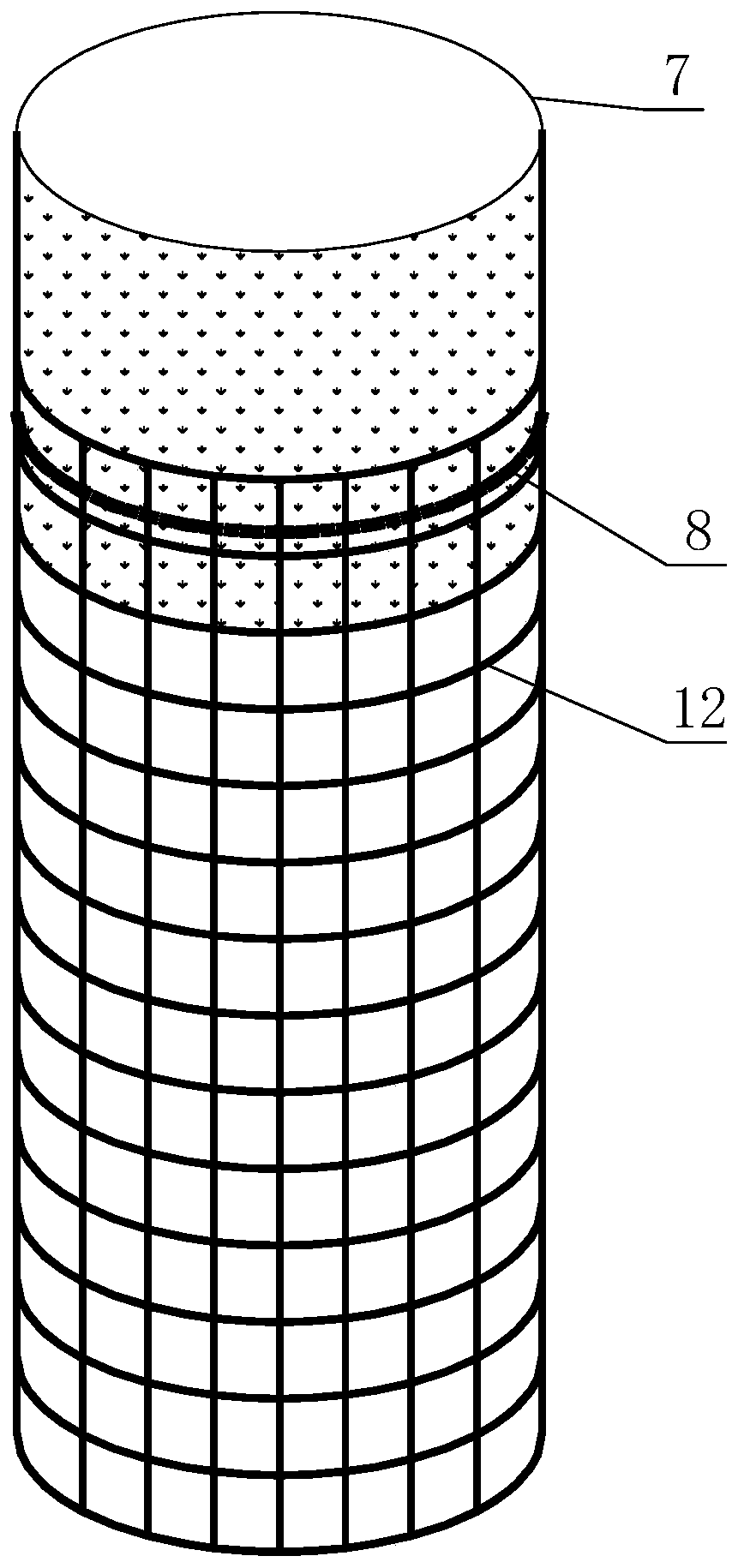

[0062] refer to figure 2 , the composite lightweight pile 1 includes a pile-forming lightweight body 11 and a composite reinforced cage 12 embedded therein, and the composite reinforced cage 12 is composed of vertical geogrids 121 and vertically spaced The set annular geogrid 122 is formed, the ve...

Embodiment 2

[0066] Such as Figure 1-4 As shown, a kind of design method of equal-load replacement light soil side wide subgrade structure described in embodiment 1 described in this embodiment, the method comprises the following steps:

[0067] ①. Preliminary determination of composite lightweight pile 1 pile diameter d 0 , the unit is m; the length of one composite light pile is l, the unit is m; the distance between one composite light pile is s, the unit is m;

[0068] ②. Determine the total weight W of the lightweight soil tank 2, the soil filling layer 4 and the upper track structure by the following formula z :

[0069] W z =(B-0.5mh)shγ n1 +(B-2d-0.5mh n2 )( n2 -γ n1 )sh n2 +

[0070] 2sb 1 q 1 +(s 1 -b 1 ) sq 0 -(B-mh-0.5m△h)(γ-γ n1 )△hs

[0071] where W z is the total weight of light soil tank 2, soil filler layer 4 and upper track structure, in kN; B is the top width of side-width subgrade, in m; b is the bottom width of side-width subgrade, in m; m is the exis...

Embodiment 3

[0079] Such as Figure 1-4 As shown, this embodiment shows the design method of equal-load replacement of light-weight soil side wide subgrade structure. The specific design process: the design speed of a new high-speed railway is 300km / h, and the line spacing is s 1 4.8m To introduce the existing ballastless railway, it is necessary to fill the roadbed adjacent to the existing ballastless track with a height of 3.2m and a slope ratio of 1.5 for side width construction. The stratum is silty clay, and the gravity γ is 19kN / m 3 . In order to eliminate the influence of the side width roadbed on the existing ballastless railway, the design intends to adopt the equal load replacement light soil side width roadbed structure of the present invention. During the design process, the cantilever thickness d of the light weight soil tank 2 is 1.0m, and the The foundation depth Δh is 1.0m, and the weight of light soil γ n1 To take 5kN / m 3 , thickness of soil filling layer h n2 To take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com