Intermittent siphon type biological filter for aquaculture

An aquaculture, siphonic technology, applied in sustainable biological treatment, chemical instruments and methods, animal husbandry wastewater treatment, etc., can solve problems such as complex structure, achieve low operating costs, wide popularization and application, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

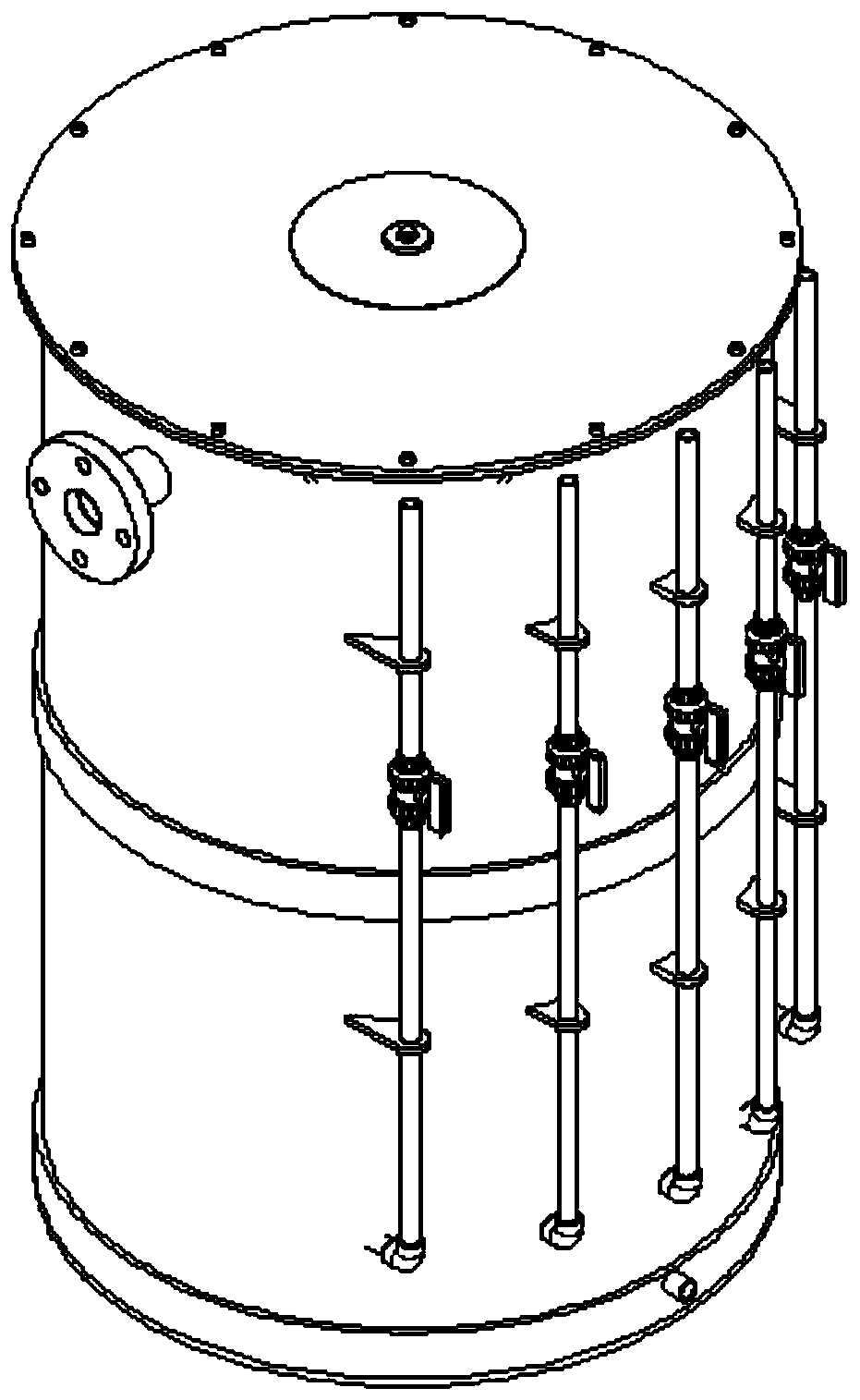

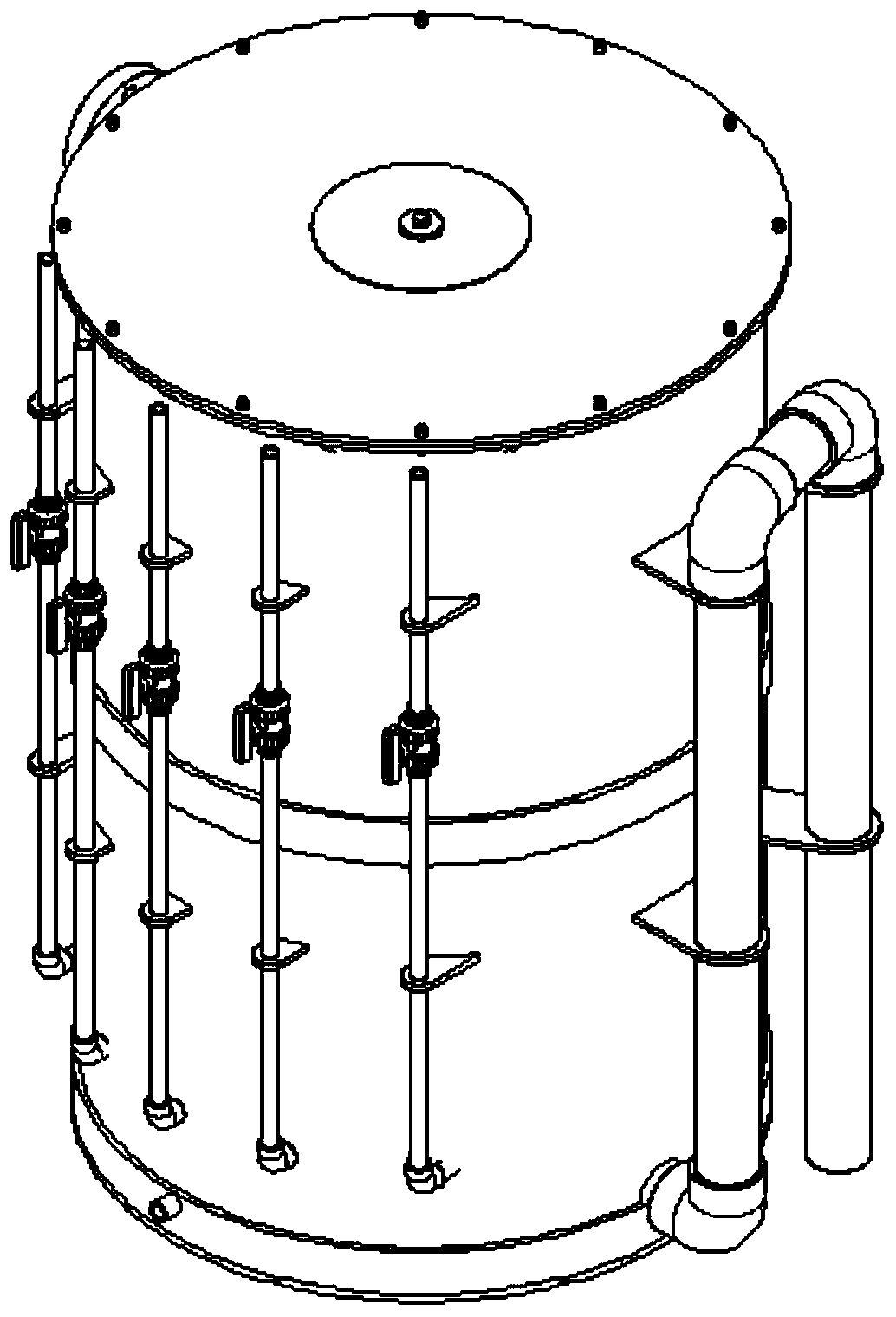

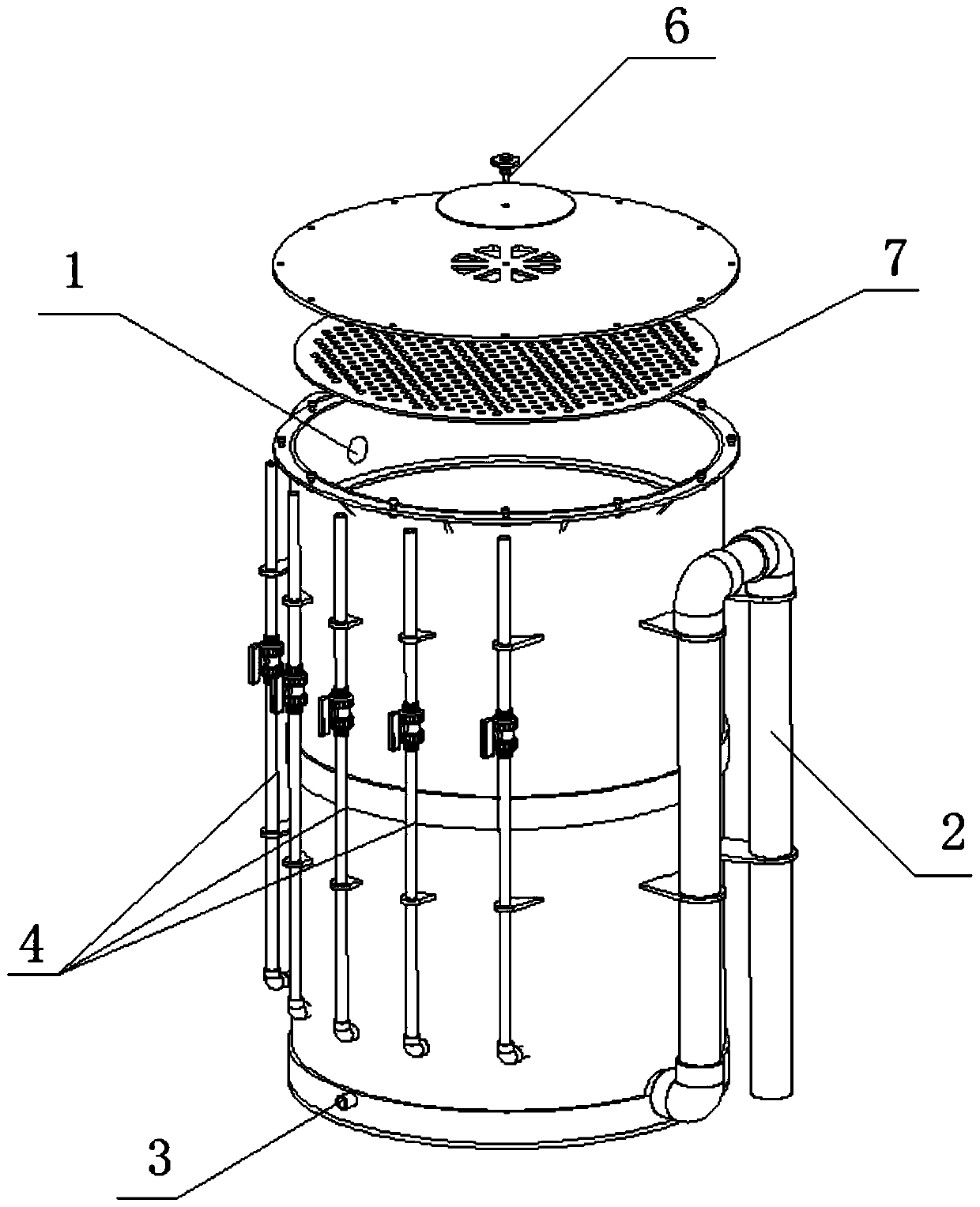

[0037] see Figure 1-7 , an intermittent siphon type biological filter for aquaculture, comprising a filter material cylinder 9; the top of the filter material cylinder 9 is provided with an exhaust check valve 6, and the interior is fixed with a hollowed-out upper filter material baffle 7 and a lower filter material Baffle plate 8; a water inlet 1 is provided at a position higher than the upper filter material baffle plate 7 on the side wall of the filter material cylinder, and a water outlet is provided at a position lower than the lower filter material baffle plate 8 on the side wall. An inverted U-shaped water outlet pipe 2 is connected, and the end of the lower bend of the water outlet pipe 2 is lower than the water outlet; the filter material cylinder 9 is located near the height of the lower filter material baffle plate 8 and is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com