Capping and uncapping equipment for chip coating

A chip and equipment technology, applied in the field of cap closing and dismantling equipment, can solve problems such as inaccurate positioning, untimely detection of fixture problems, batch NG problems, etc., to achieve convenient and simple cap closure and cap disassembly, and convenient connection to the Internet of Things , precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

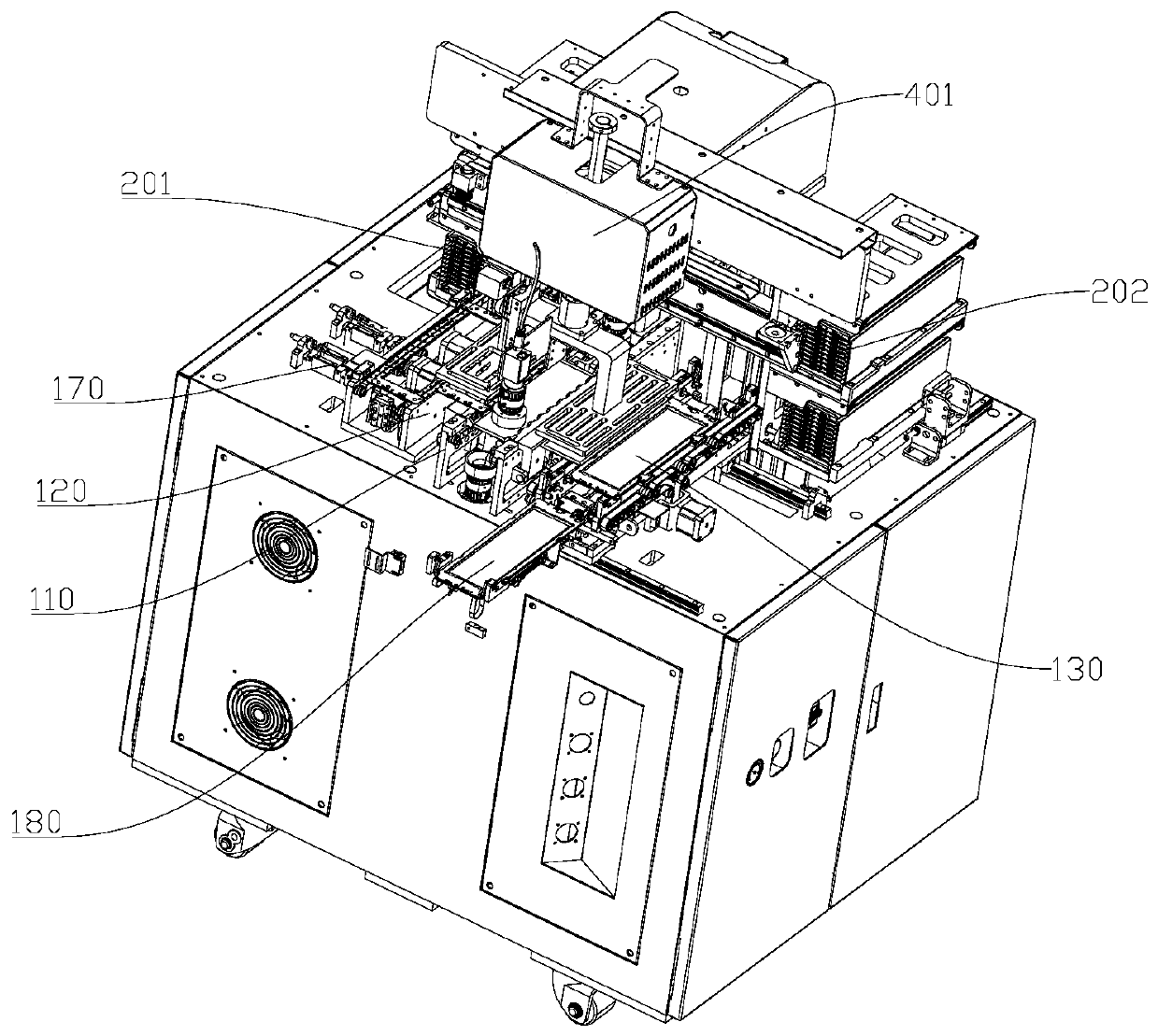

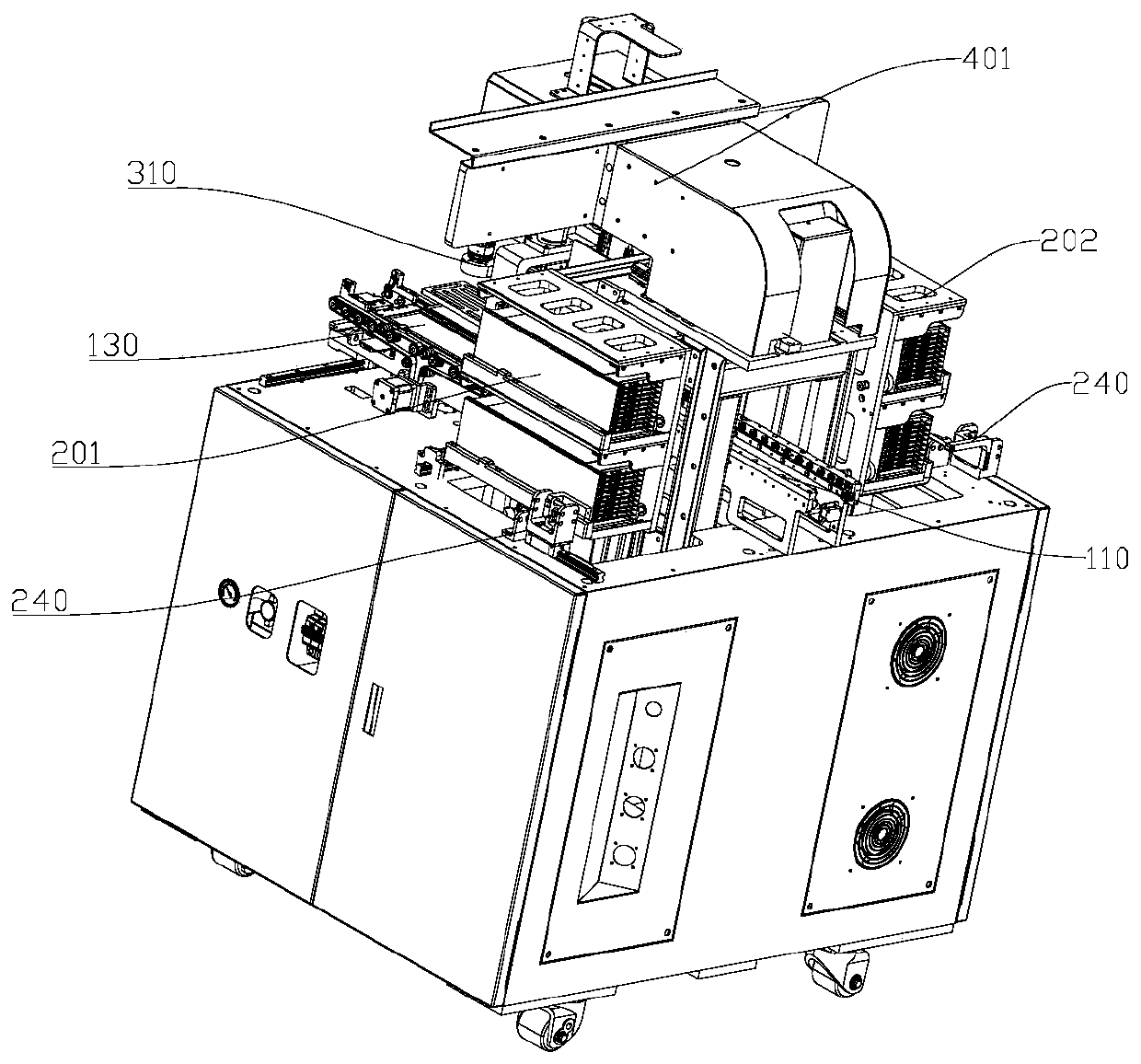

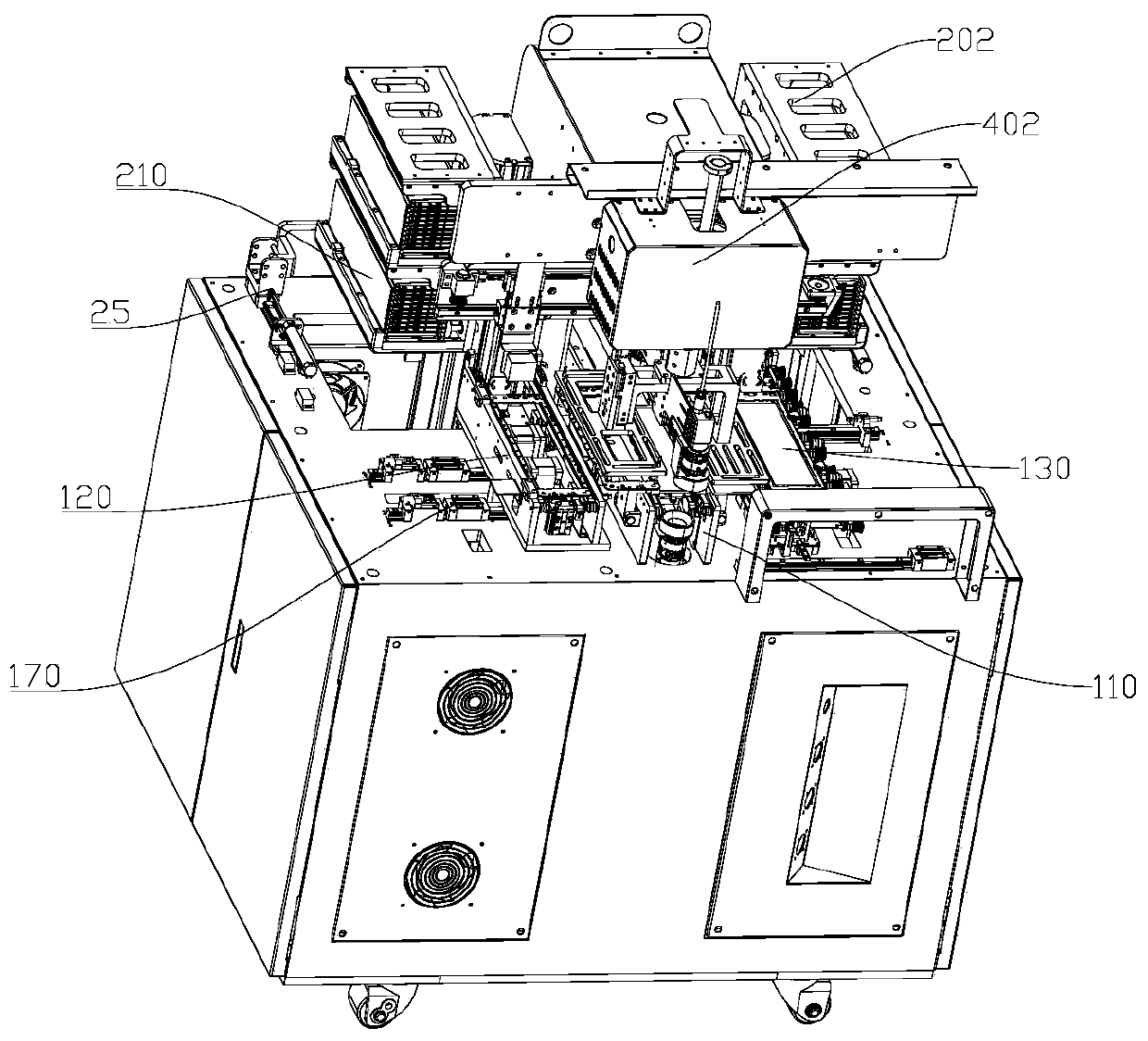

[0043] See Figure 1-Figure 11 , a capping and decapping equipment for chip coating, including a capping part and a decapping part, wherein,

[0044] The cover-closing part includes: a code-closing code-scanning mechanism for scanning the PCBA board, the cover plate and the fixture respectively, and a first handling manipulator, which sequentially sucks the PCBA board, the cover plate , and then assemble the PCBA board and the cover plate in the jig after being adjusted by a visual mechanism;

[0045] The cover removal part includes: a cover removal mechanism that disassembles the processed lid product; a cover scanning code scanning mechanism that scans the disassembled PCBA board, cover plate and jig; and is used to pick up The disassembled cover plate and the second handling manipulator of the PCBA board.

[0046] The PCBA board, cover plate and jig are respectively scanned by the cover scanning mechanism, and the visual mechanism is used to assist the first handling mani...

Embodiment 2

[0063] A cover and cover removal equipment for chip coating, including a code scanning mechanism, a handling manipulator, a PCBA board feeding track, a jig track, a cover track, a jig hopper, a cover hopper, a visual mechanism, and a cover removal Mechanism and handling manipulator; in the cover-closing process, the jigs in the jig silo are transported by the jig track and arrive at a predetermined position after being scanned by the code scanning mechanism, and the PCBA board feeding track provides The PCBA board is scanned by the code-scanning mechanism, picked up by the handling manipulator, and arranged in the jig that reaches the predetermined position with the assistance of the vision mechanism. The cover plate in the cover plate bin passes through the The cover plate is transported by track, and the scanning mechanism is picked up by the handling manipulator after scanning the code, and with the assistance of the vision mechanism, the PCB board is sandwiched with the jig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com