Feed conditioning granulator

A granulator and tempering technology, which is applied in the direction of feed, mixer, mixer accessories, etc., can solve the problems of difficult discharge of materials, waste of steam, easy escape, etc., to improve the effect of conditioning and sterilization, and to avoid steam The effect of loss and avoiding heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

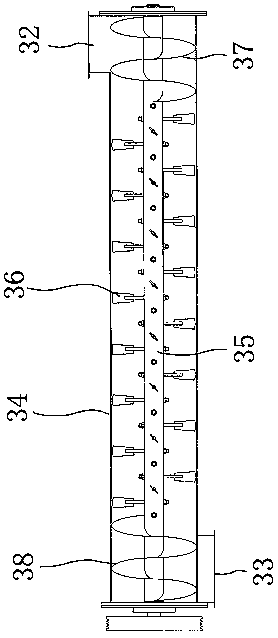

[0012] The structure and operating principle of the feed conditioning granulator of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 and figure 2 As shown, the structure schematic diagram of the feed conditioning granulator of the present invention, the feed conditioning granulator of the present invention includes a frame body 1 and a feeding mechanism 2 positioned at the top of the frame body, a conditioner 3 positioned below the feeding mechanism 2 and a The granulation mechanism 4 located under the conditioner 3 . The conditioner 3 includes a power mechanism 31, a housing 34 with a feed inlet 32 and a discharge outlet 33, a stirring shaft 35 and a stirring fin 36 located on the stirring shaft, and the feed inlet 32 and the discharge outlet 33 are located at On the sidewalls at both axial ends of the casing 34, a first spiral fin plate 37 is provided on the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com