Liquid cooling plug-in assembly, liquid cooling plug-in device and battery pack assembly

A plug-in device and connector technology, which is applied to the parts of the connection device, battery, coupling device, etc., can solve the problems of insufficient floating amount, splashing, liquid outflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be more clearly and completely described below by means of embodiments and in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiments.

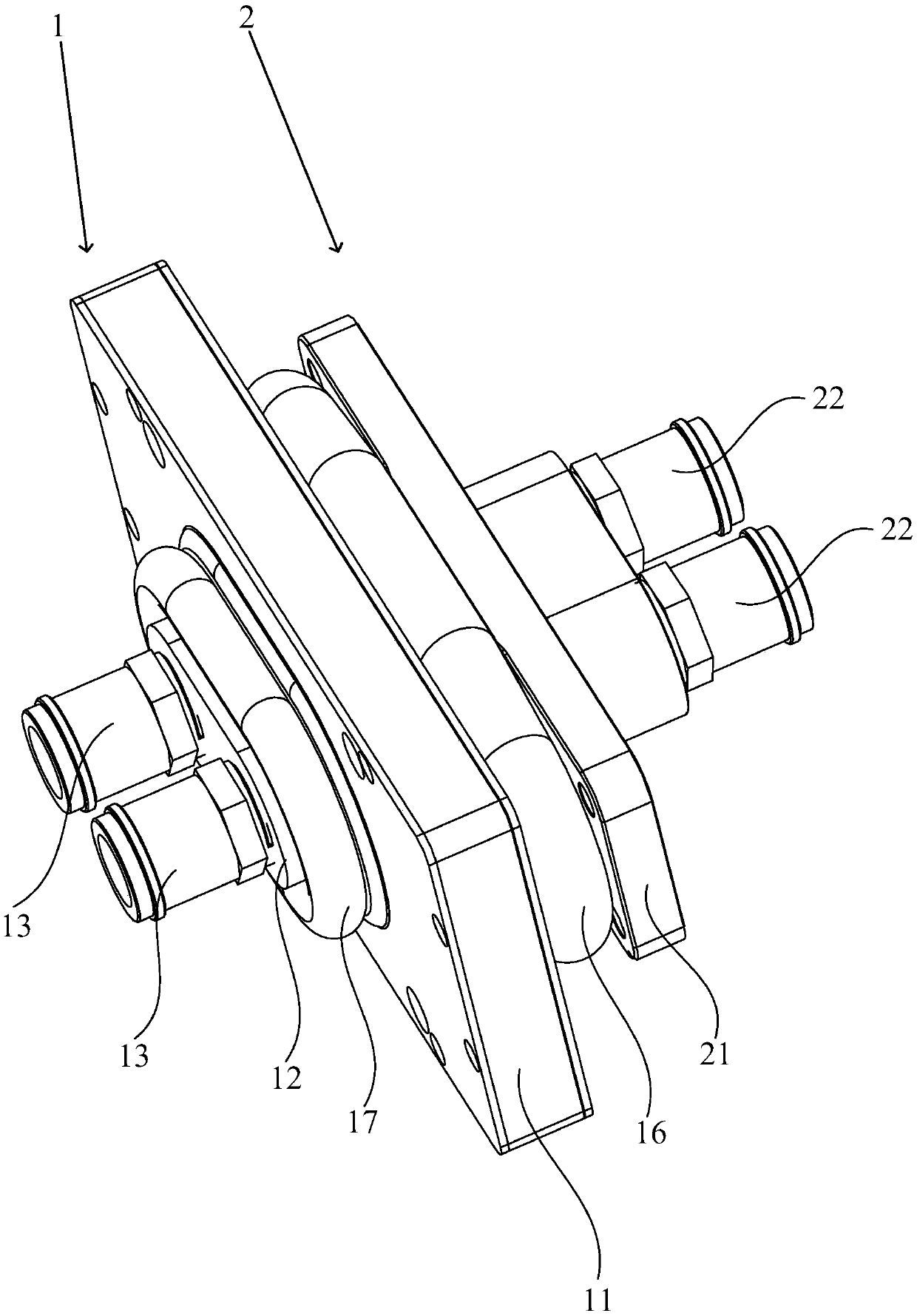

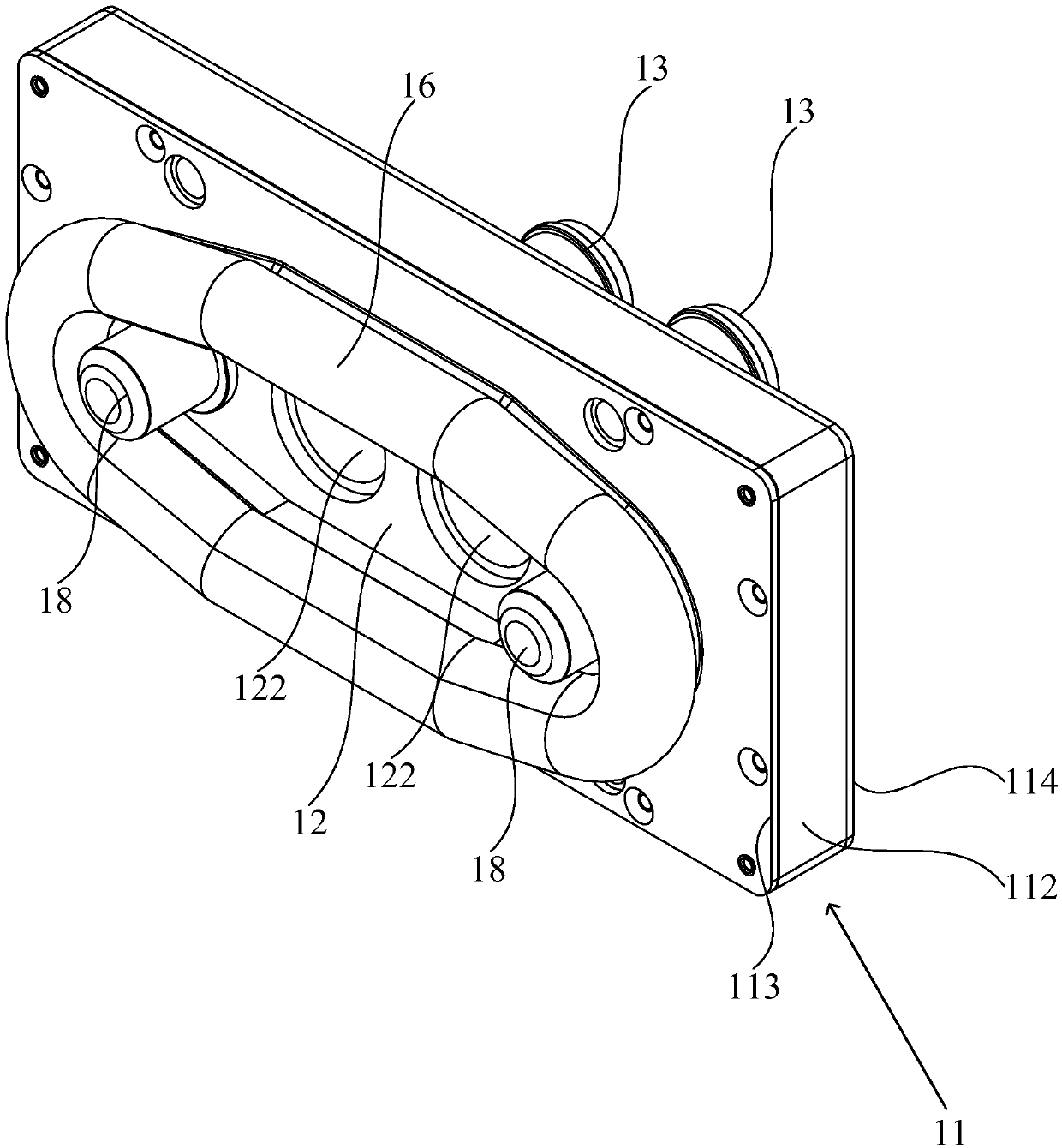

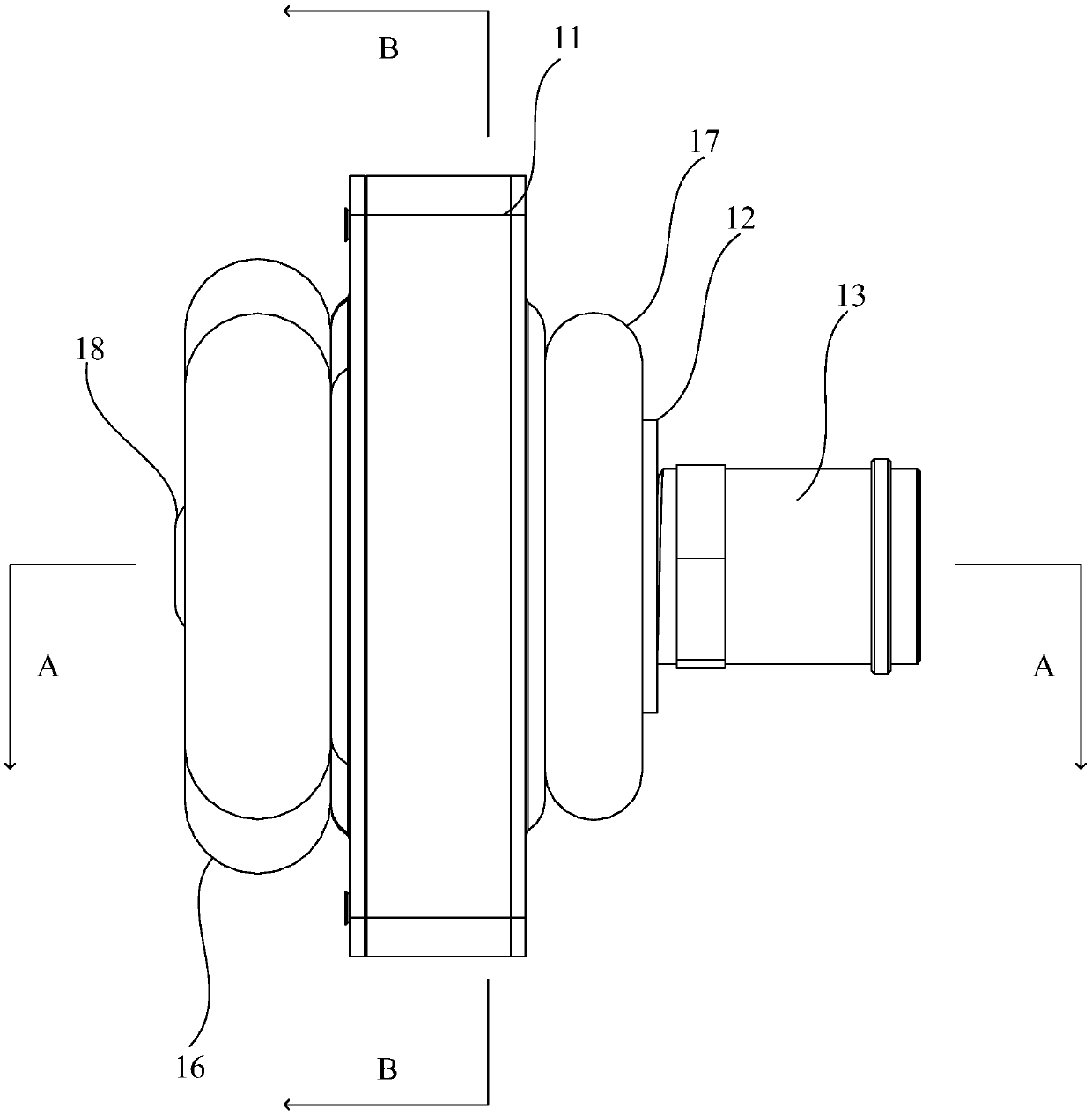

[0076] Such as Figure 1 to Figure 7 As shown, the liquid-cooled plug-in device of the embodiment of the present invention includes a liquid-cooled plug-in assembly 1 and a mating plug-in assembly 2 , and the mating plug-in assembly 2 is detachably connected to the liquid-cooled plug-in assembly 1 . The liquid-cooled plug-in assembly 1 includes a first fixed plate 11, a floating plate 12, at least one first elastic member 14 and a plurality of connectors 13, and the plurality of connectors 13 are all connected to the floating plate 12, and inside the first fixed plate 11 A movable cavity 111 is opened, and the floating plate 12 and the first elastic member 14 are located in the movable cavity 111 , and the floating plate 12 is floatingly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com