Double-heat-source rotational flow flash calcining system and double-heat-source rotational flow flash calcining method

A dual heat source, calcination technology, applied in the direction of lighting and heating equipment, charge processing type, furnace components, etc., can solve the problems of complex equipment, energy consumption reduction, bulky, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

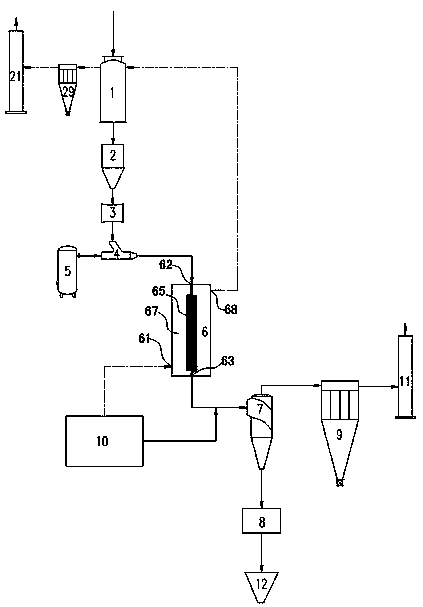

[0029] A specific embodiment of the present invention will be described below with reference to the accompanying drawings.

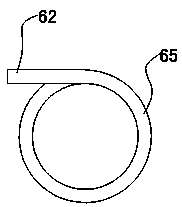

[0030] like figure 1 As shown, the dual heat source swirl flash calcination system according to a specific embodiment of the present invention includes a drying unit 1 for drying powder raw materials connected in sequence, a feeding bin 2, a rotary feeder 3 controlled by frequency conversion, a Venturi Inner feeder 4, flash calcination unit 6, cyclone secondary heating material collection unit 7, material cooling unit 8 connected to cyclone secondary heating material collection unit 7 and first flue gas treatment unit 9, hot blast stove 10, The first chimney 11, wherein the hot blast stove 10 is connected to the high-temperature flue gas inlet 61 of the flash calcination unit 6 to complete the first calcination reaction in the flash calcination unit 6, the first calcination reaction is calcium hydroxide decomposition reaction, Another road connects the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com