A textile printing and dyeing cooling device with waste water collection function

A textile printing and dyeing and cooling device technology, which is applied to the processing of textile materials, equipment configuration, textiles and papermaking, heating/cooling fabrics, etc., can solve problems such as easy corrosion of devices, easy reduction of cleanliness of the operating environment, and easy accumulation of water in the device, to achieve High structural stability, simple and efficient structure, large filtration area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is only a preferred embodiment of the present invention, and does not limit the scope of the present invention.

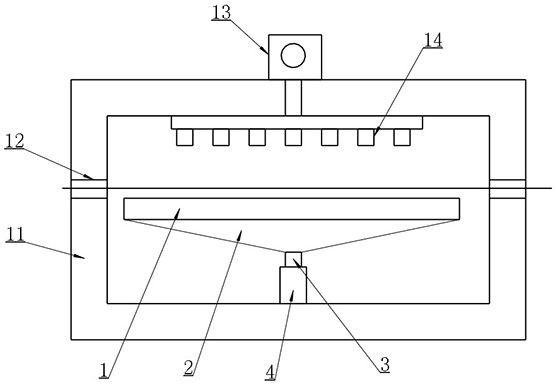

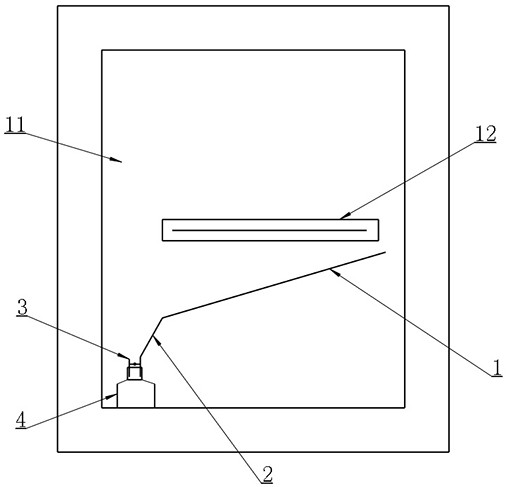

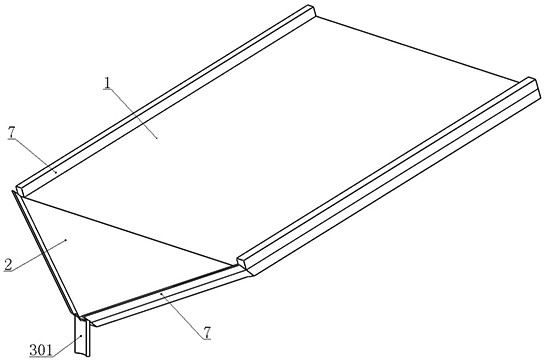

[0028] Example: as attached Figure 1 、 2 , 3, 4, 5, 6, 7, 8 and attached Figure 9 As shown, a textile printing and dyeing cooling apparatus with a wastewater collection function, comprising a cooling box 11, an inlet and outlet 12 disposed on the cooling box 11, a blower 13 disposed on the cooling box 11, and an outlet duct 14 arranged in the direction of the cloth advance is disposed under the cloth and further comprising a rectangular water connection plate 1 is provided under the cloth and inclined to the side of the cloth forward direction, a triangular deflector plate 2 disposed on the side below the rectangular water connection plate 1, Disposed on the horizontal bottom surface of the triangular deflector plate 2 of the combined threaded pipe unit 3, disposed on the combined threaded pipe unit 3 water connection bottle 4, disposed on the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com