Base asphalt, modified asphalt and preparation method

A technology of base asphalt and modified asphalt, applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, multi-stage series refining and cracking process treatment, building components, etc. Segregation and other problems occur to achieve the effect of improving compatibility, optimizing hydrocarbon composition and molecular structure, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

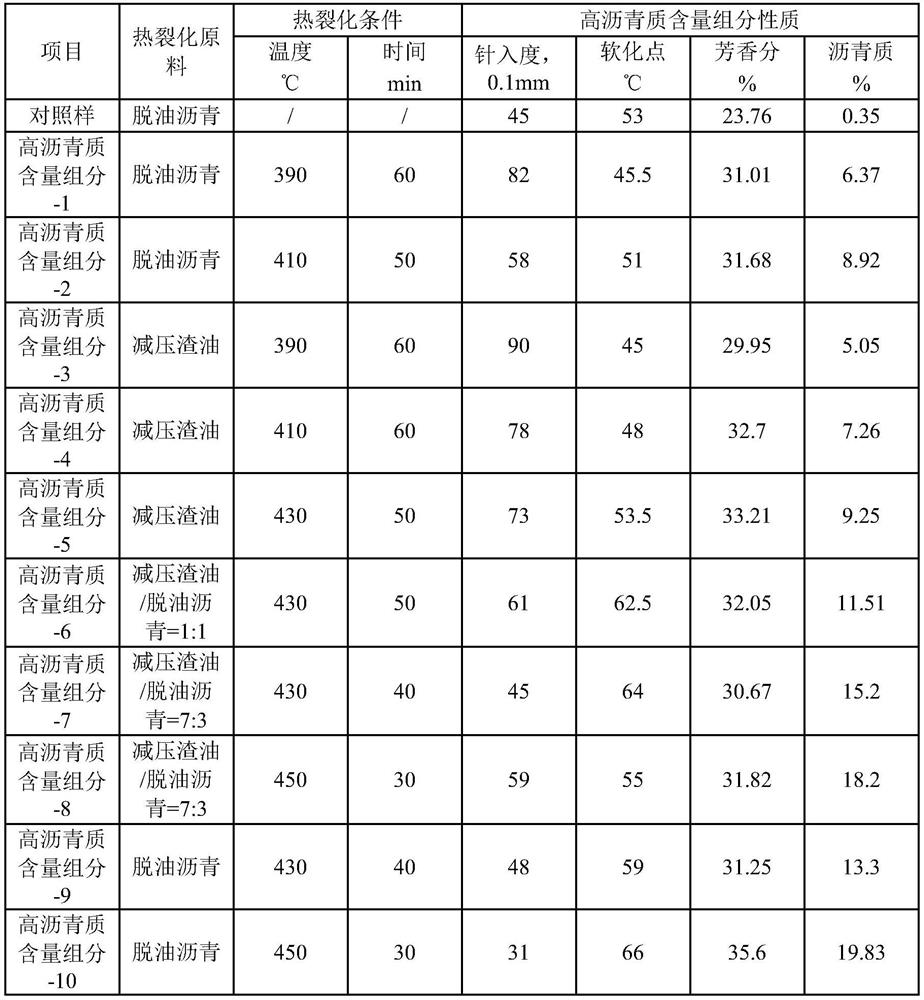

[0023] As described in the background art, the performance of the modified asphalt prepared by using the existing base asphalt is unstable, and the problem of segregation is prone to occur. In order to solve the above-mentioned technical problems, the application provides a method for preparing base asphalt, the preparation method comprising: using residual oil and / or deoiled asphalt as raw material for thermal cracking reaction to obtain a thermal cracking product, the content of asphaltene in the raw material is less than 1.0wt%, the atmospheric boiling point is higher than 350°C, and the atmospheric boiling point of the thermal cracking product is higher than 350°C; the thermal cracking product is oxidized with the aromatics-rich component to obtain matrix pitch, and the aromatics content in the aromatics-rich component is greater than 50wt%, the flash point is greater than 235°C.

[0024] Residual oil and deoiled bitumen with low asphaltene content can be thermally cracked...

Embodiment 1

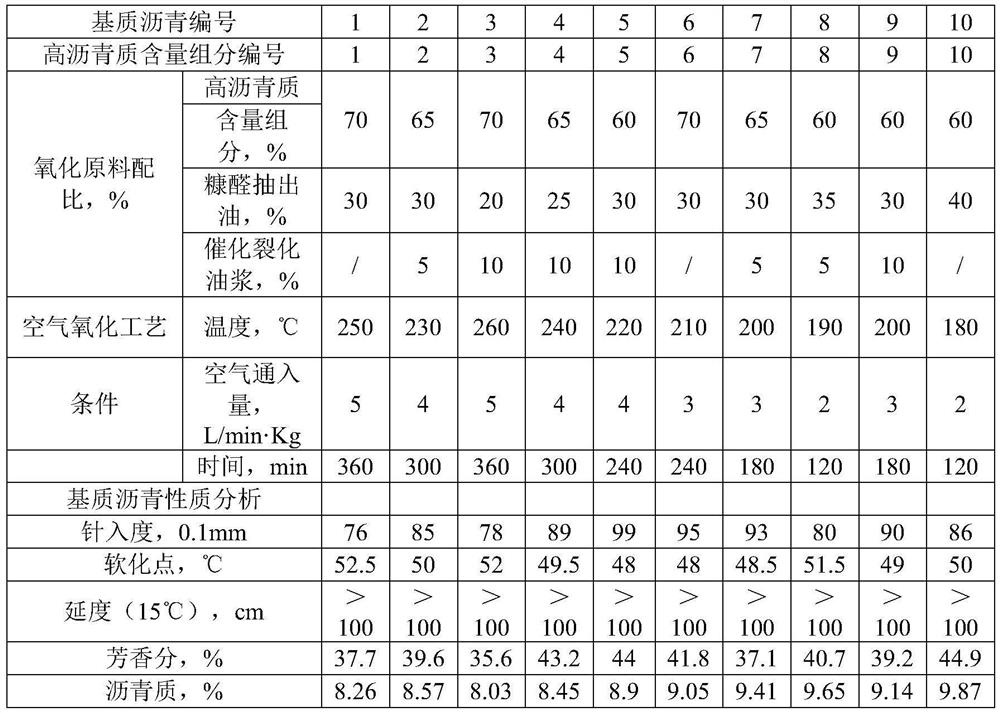

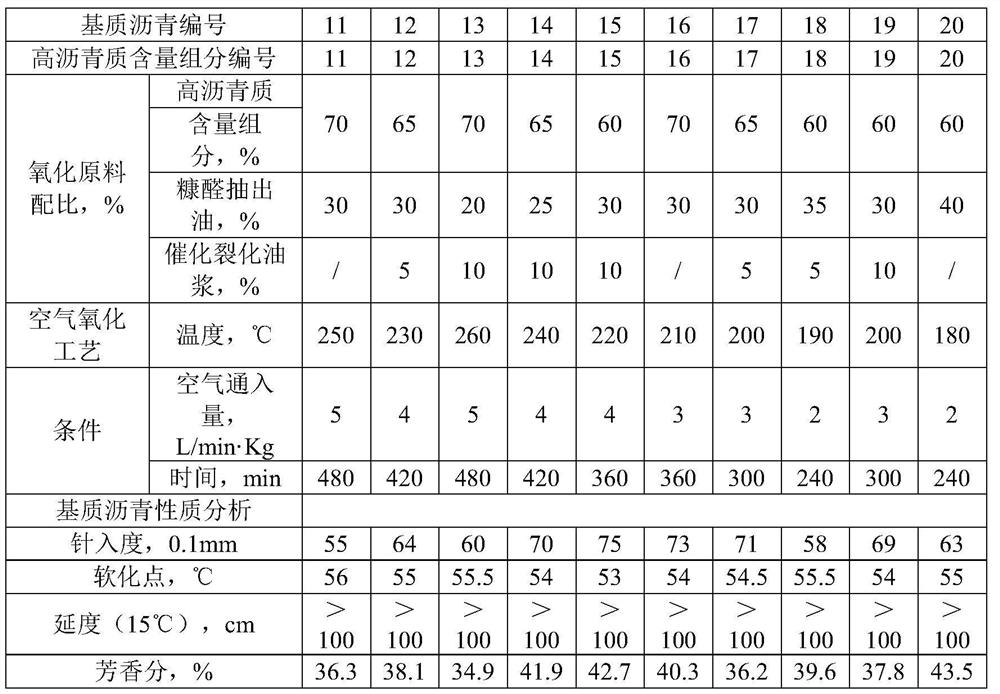

[0054] 70% high asphaltene content component-1 was mixed with 30% furfural extracted oil, and the base asphalt 1 was obtained at an air oxidation temperature of 250°C, an air flow rate of 5L / min·Kg, and an oxidation time of 360min. Add 94.6% base asphalt 1 into the container, add 5.0% SBS, disperse at 170°C with a speed of 4500r / min high-speed shear for 60min, add 0.4% stabilizer composition after heating up to 190°C, and stir and mix for 240min to obtain Modified asphalt (analysis results of modified asphalt properties are shown in Tables 4 and 5), and the obtained SBS modified asphalt index meets the technical requirements of I-C polymer modified asphalt in "Technical Construction Specifications for Highway Asphalt Pavement" JTG F40-2004.

Embodiment 2

[0056] Using 65% high asphaltene content component-2 mixed with 30% furfural extracted oil and 5% catalytic cracking oil slurry, the air oxidation temperature is 230°C, the air flow rate is 4L / min·Kg, and the oxidation time is 300min to obtain matrix asphalt 2. Add 94.6% of base asphalt 2 into the container, add 5.0% SBS, and disperse at 170°C with a speed of 4500r / min for 45min at high shear speed, add 0.4% stabilizer composition after heating up to 190°C, and stir and mix for 180min to obtain Modified asphalt (analysis results of modified asphalt properties are shown in Tables 4 and 5), and the obtained SBS modified asphalt index meets the technical requirements of I-C polymer modified asphalt in "Technical Construction Specifications for Highway Asphalt Pavement" JTG F40-2004.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com