Building timber cutting device

A cutting device and wood technology, applied in wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problems of low cutting efficiency and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

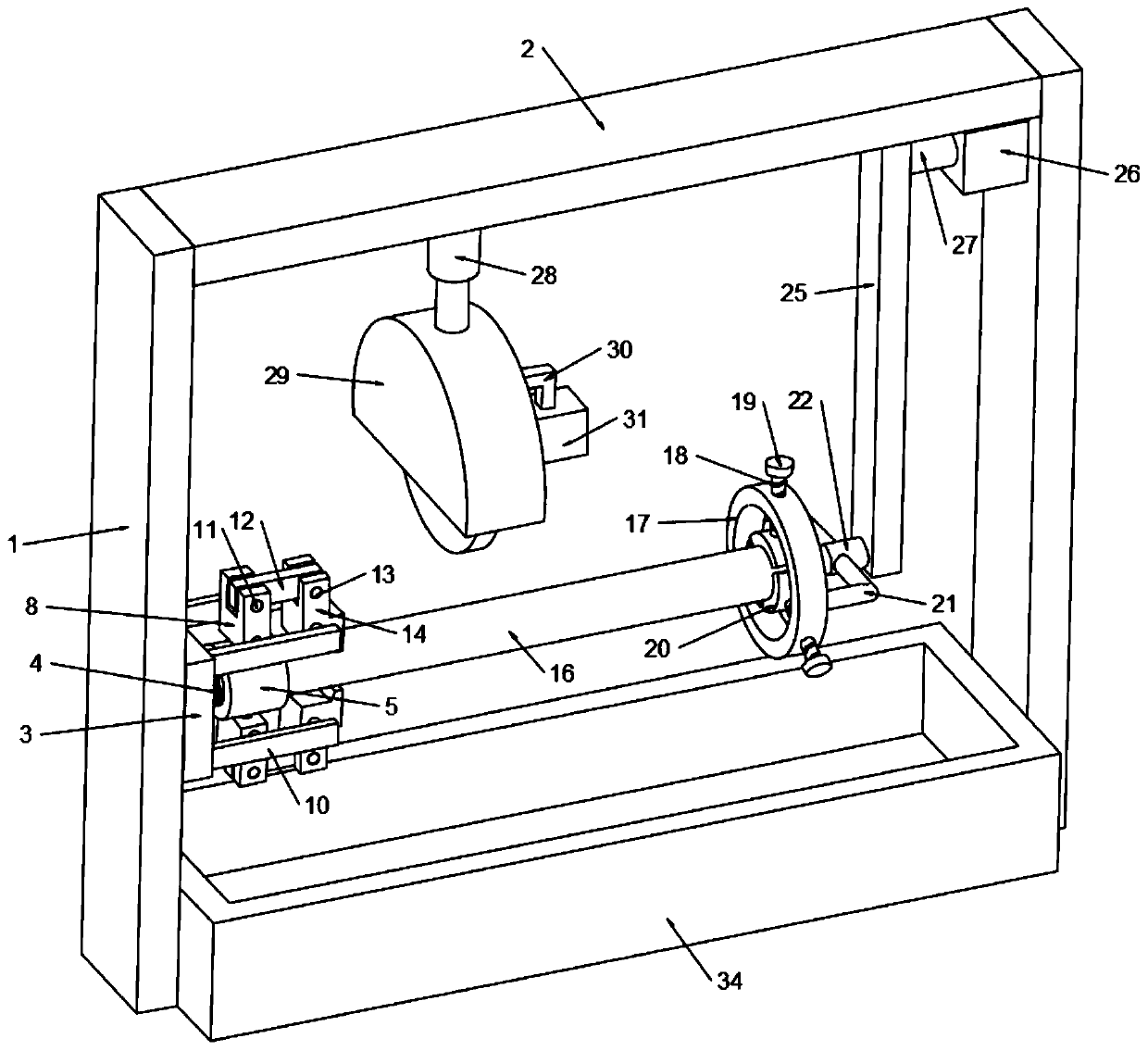

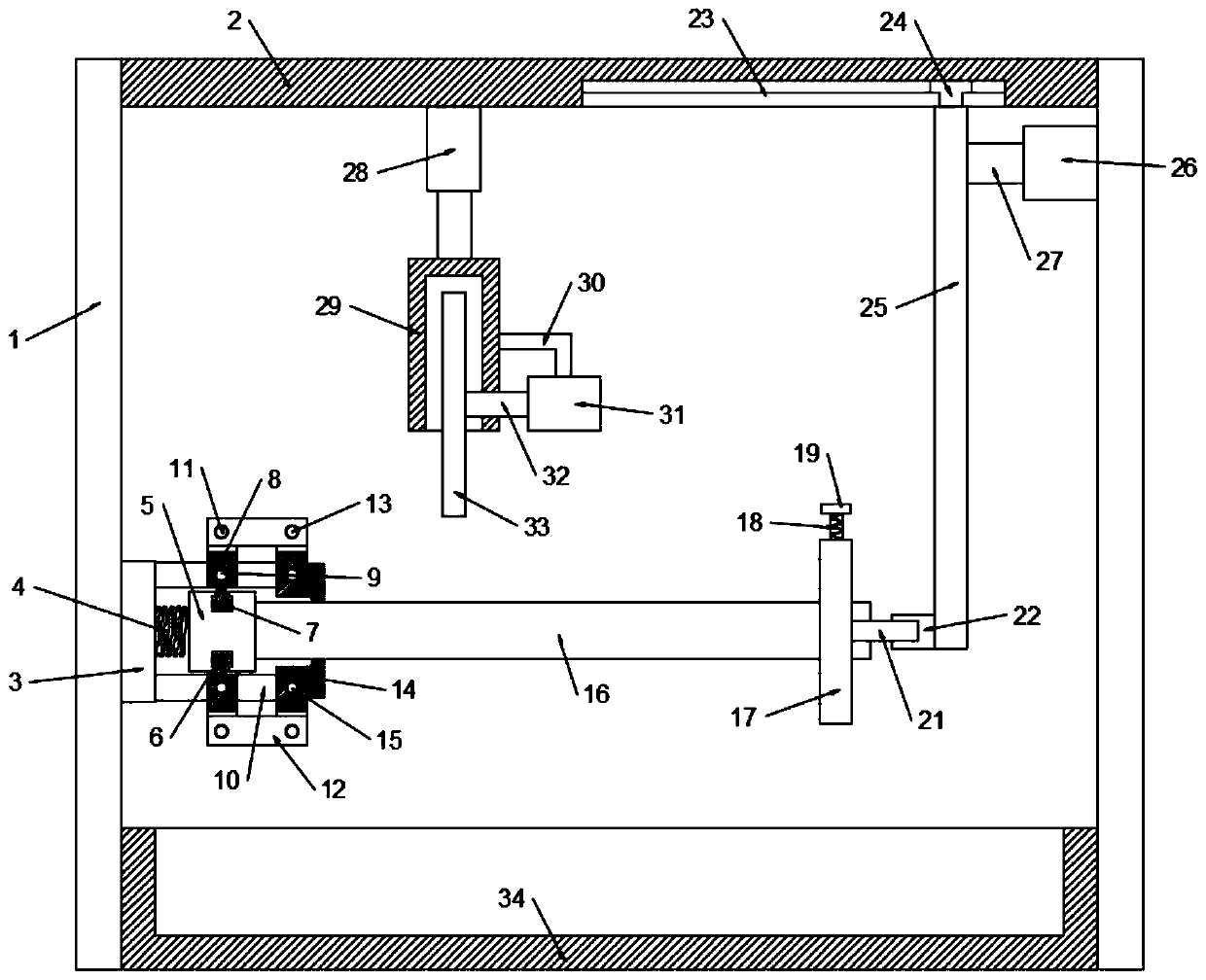

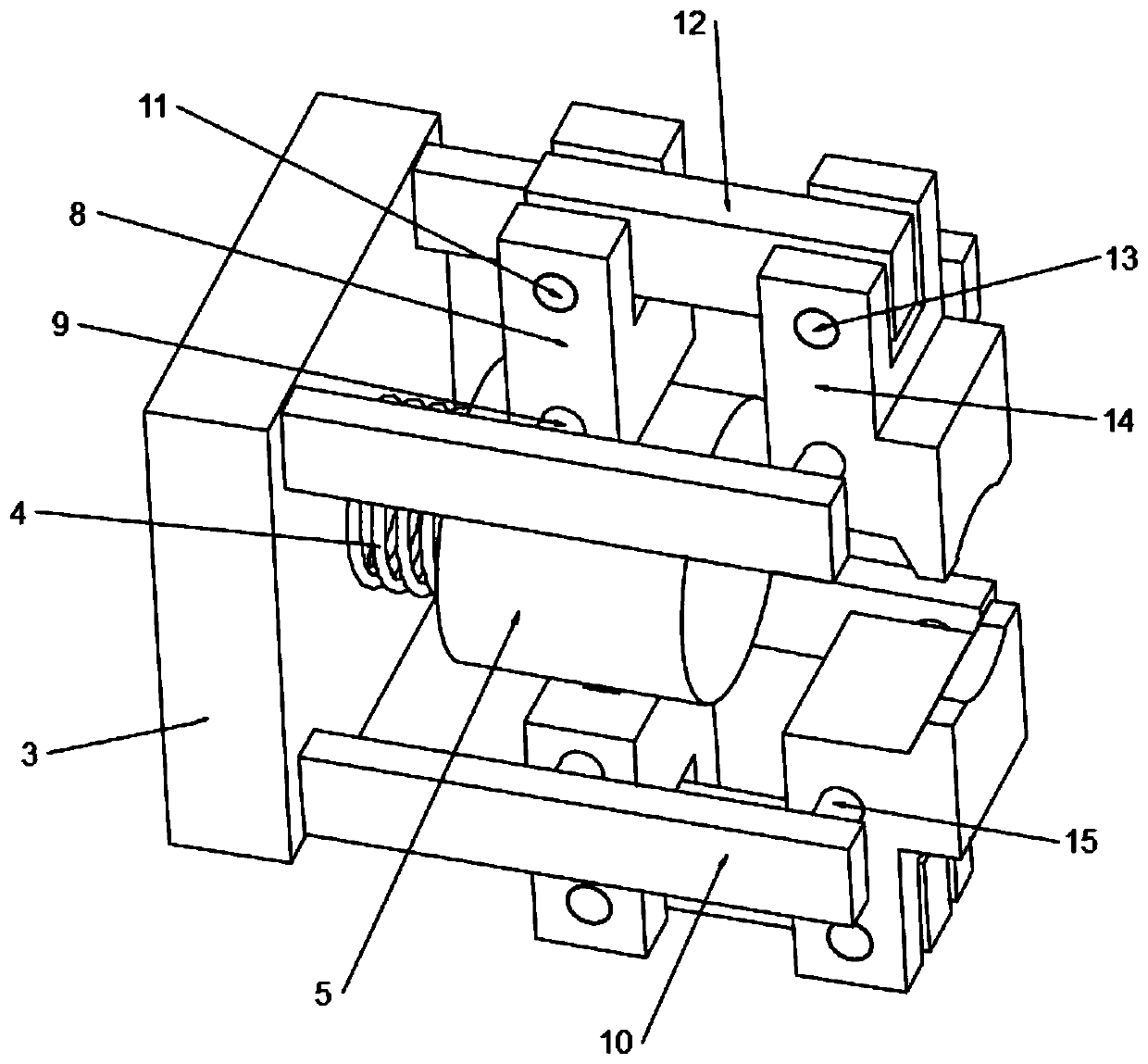

Embodiment 1

[0020] see Figure 1-3 , in an embodiment of the present invention, a construction timber cutting device includes a bracket 1, the upper end of the bracket 1 is fixedly connected with a top plate 2, the side wall of the bracket 1 on the left side is provided with a fixing seat 3, and the right side wall of the fixing seat 3 is A spring 4 is arranged on the top, and the end of the spring 4 is fixedly connected with a round table 5, and grooves 6 are arranged on the upper and lower side walls of the round table 5, and a boss 7 is installed in the groove 6, and the boss 7 is fixedly connected with a connecting block 8, and the connecting block 8 is hinged with a hinged shaft-9 near the end of the boss 7, the fixed seat 3 is provided with a fixed plate 10, the end of the hinged shaft-9 is fixedly connected on the fixed plate 10, and the end of the connecting block 8 away from the boss 7 is hinged with a Articulation shaft 2 11, articulation shaft 2 11 is rotatably connected with c...

Embodiment 2

[0027] In order to facilitate the collection of the cut round wood 16, this embodiment is further improved on the basis of Embodiment 1. The improvement is: a storage box 34 is arranged between the supports 1, and the storage box 34 is located at the fixed block 14 Directly below, the cut circular timber 16 falls off from the fixing block 14 and falls into the storage box 34 located directly below, which facilitates the collection and arrangement of the circular timber 16 and improves the convenience of the device.

[0028] The working principle of this embodiment is: in order to facilitate the collection of the cut round wood 16, a storage box 34 is arranged between the supports 1, the storage box 34 is located directly below the fixed block 14, and the cut round wood 16 16 falls off from the fixed block 14 and falls into the storage box 34 located directly below, which facilitates the collection and arrangement of the round timber 16 and improves the convenience of the device. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com