Numerical control machine tool rotary cutter disc with cutter heads being replaced conveniently

A technology of CNC machine tools and rotary cutterheads, which is applied in milling cutters, milling machine equipment, manufacturing tools, etc., and can solve problems such as difficult removal or installation, and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

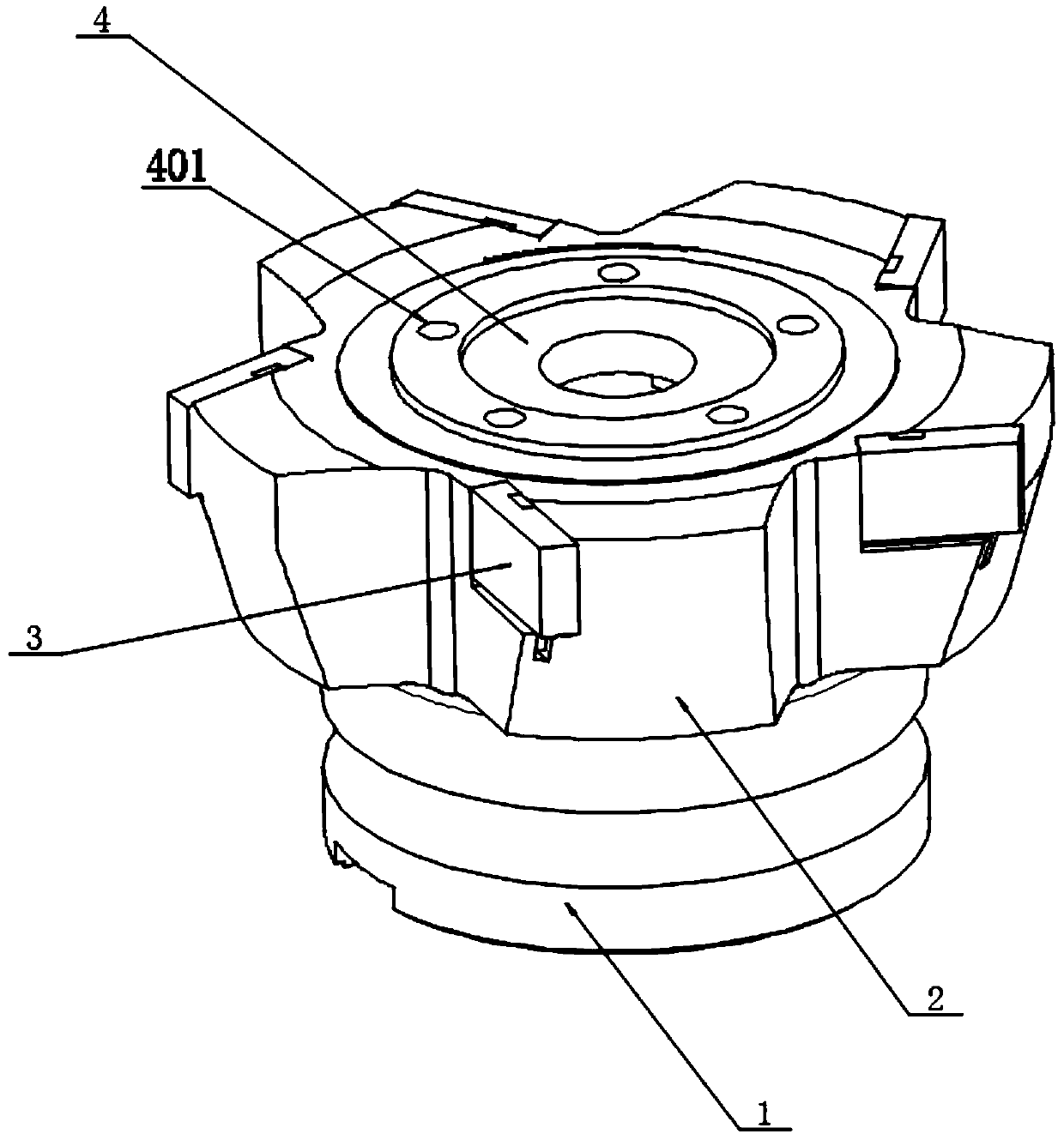

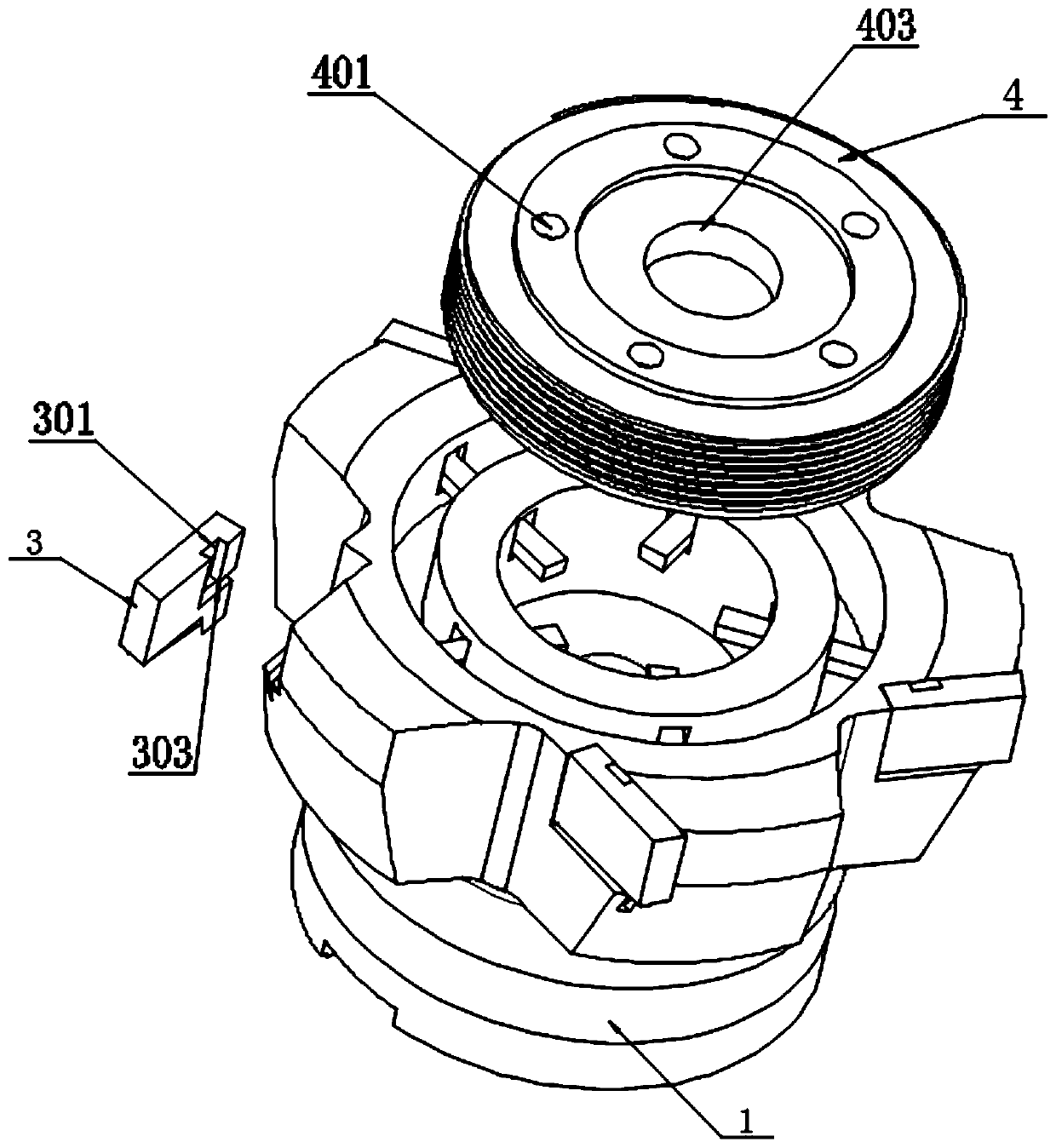

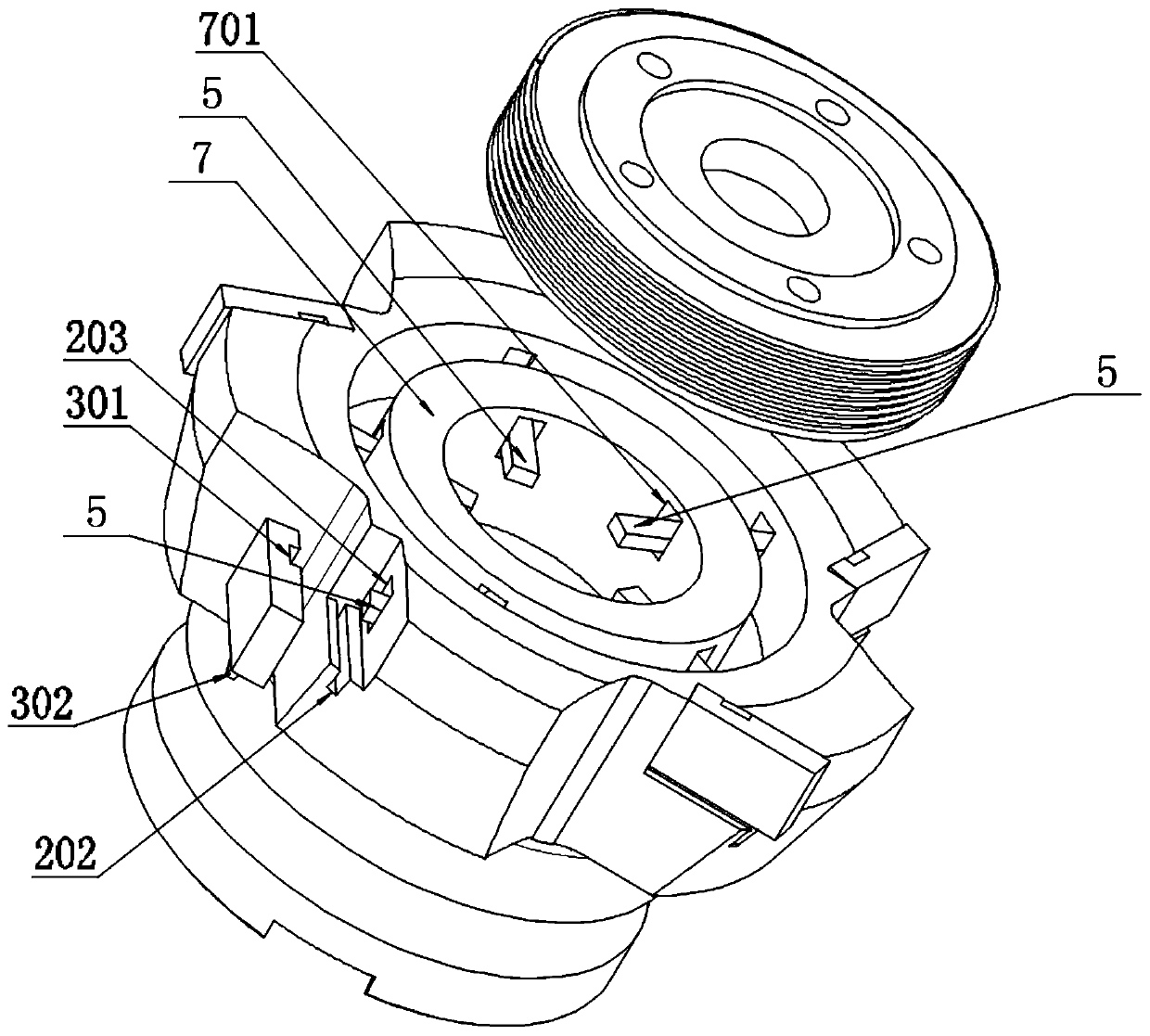

[0028] see Figure 1 to Figure 8 , an embodiment provided by the present invention: a CNC machine tool rotary cutter head for easy replacement of the cutter head, including a handle 1 and a fixed seat 4; The five-station tool holders 2 are also equipped with alloy material cutter heads 3, and a through hole is left in the middle of the five tool holders 2, and an inner ring seat 7 is machined on the inner ring of the through hole, and the inner ring seat An annular channel is formed between 7 and the knife seat 2, and a threaded ring 204 is provided on the inner wall of the annular channel, and five springs 6 are uniformly welded in the annular channel, and a spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com