Z-axis linear motor mass block forming die

A molding mold and quality block technology, applied in the field of motor manufacturing, can solve the problems of high product density uniformity, low difficulty in molding mold manufacturing, and high difficulty in molding mold manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

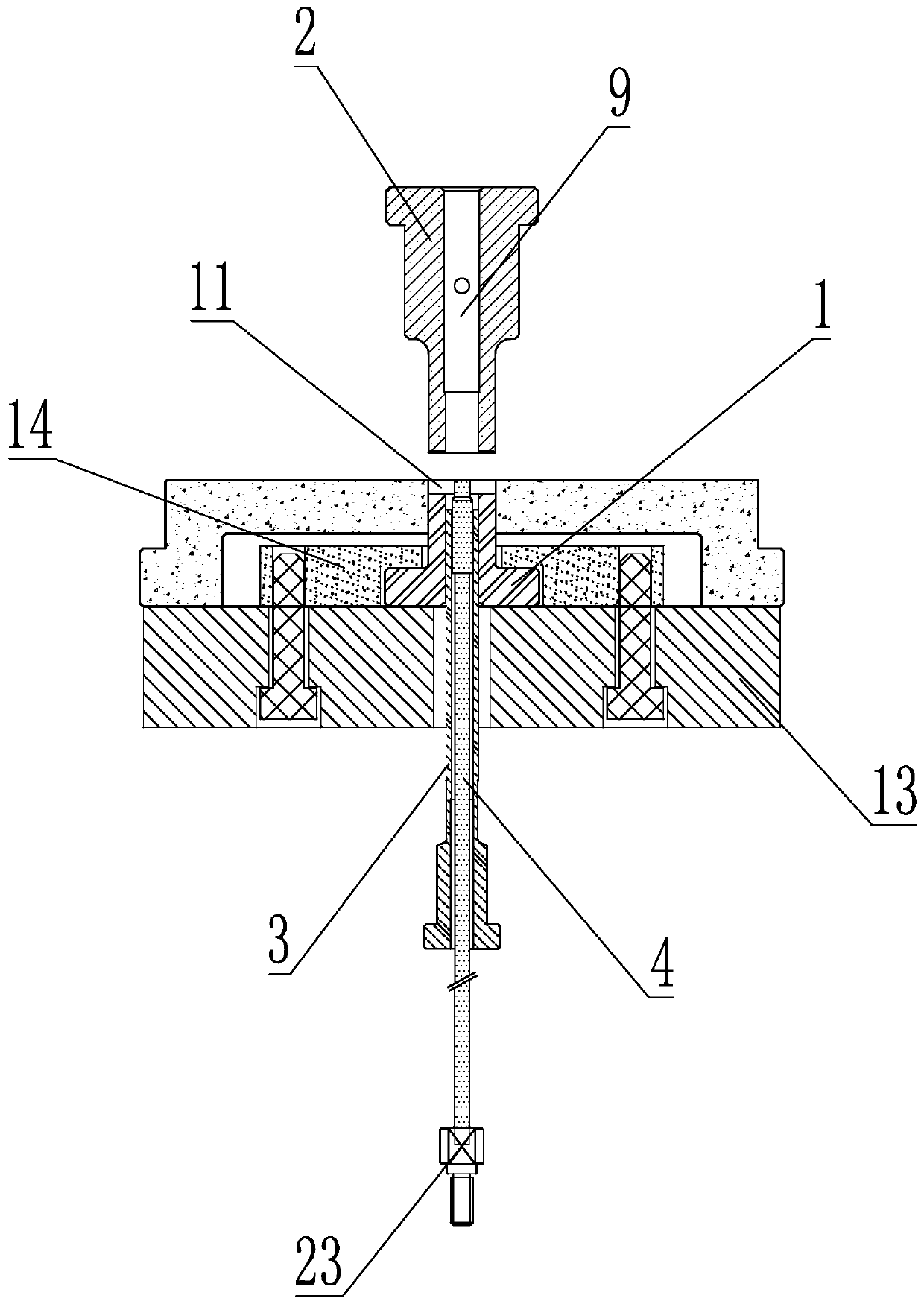

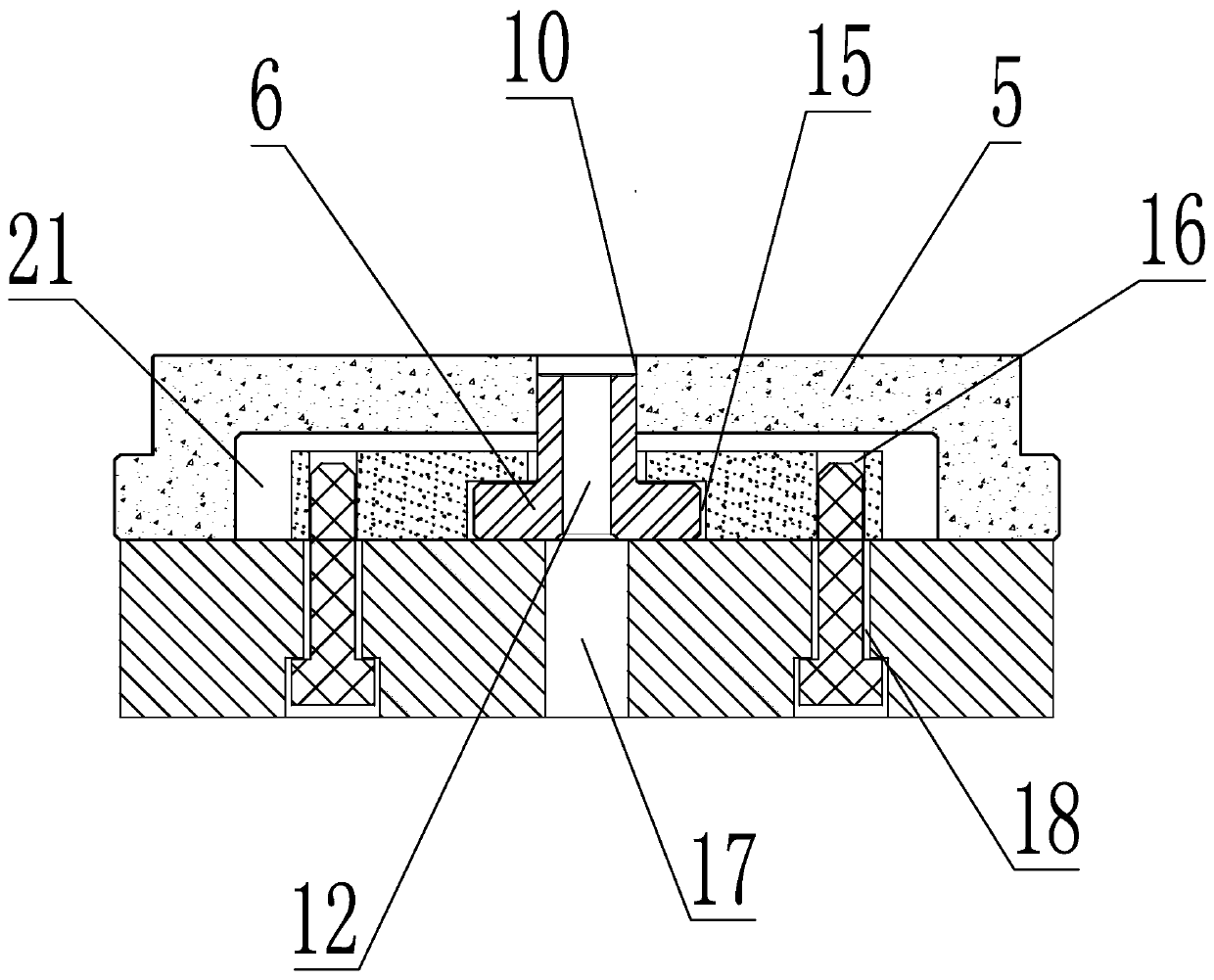

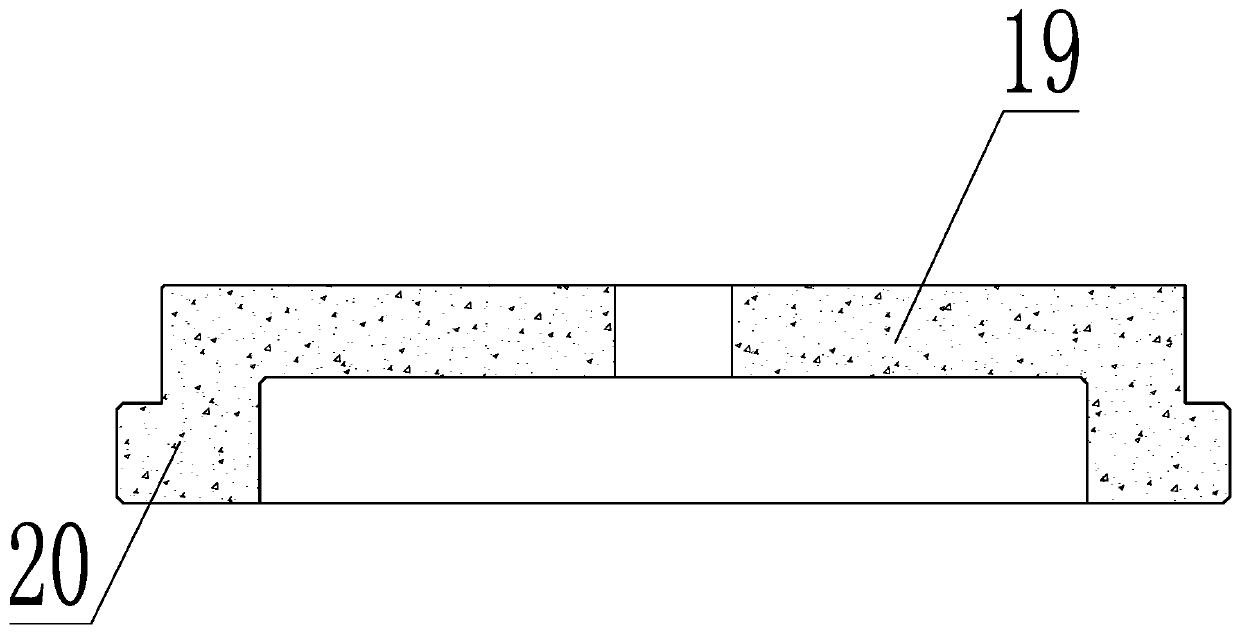

[0027] Such as Figure 1 to Figure 4 As shown, a Z-axis linear motor mass forming mold includes a mold assembly and a mold base assembly. The mold assembly includes a die 1, an upper punch 2, a lower punch 3 and a mandrel 4. The die includes an upper die 5 and a lower die. Die 6, the mold base assembly includes a lower die fixture for limiting the lower die, the lower punch includes a first processing segment 7 and a second processing segment 8 along its length, the upper punch, the die and the lower punch Arranged coaxially, the mandrel can slide into or out of the upper punch forming hole 9 of the upper punch, and the lower die partly penetrates into the upper die forming hole 10 of the upper die, and the height of the upper die is greater than that of the lower die , the upper die and the lower die cooperate to form a die step 11 coaxial with the mandrel; the profile of the cross section of the lower die is "T" shaped, and the lower die is provided with a lower die forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com