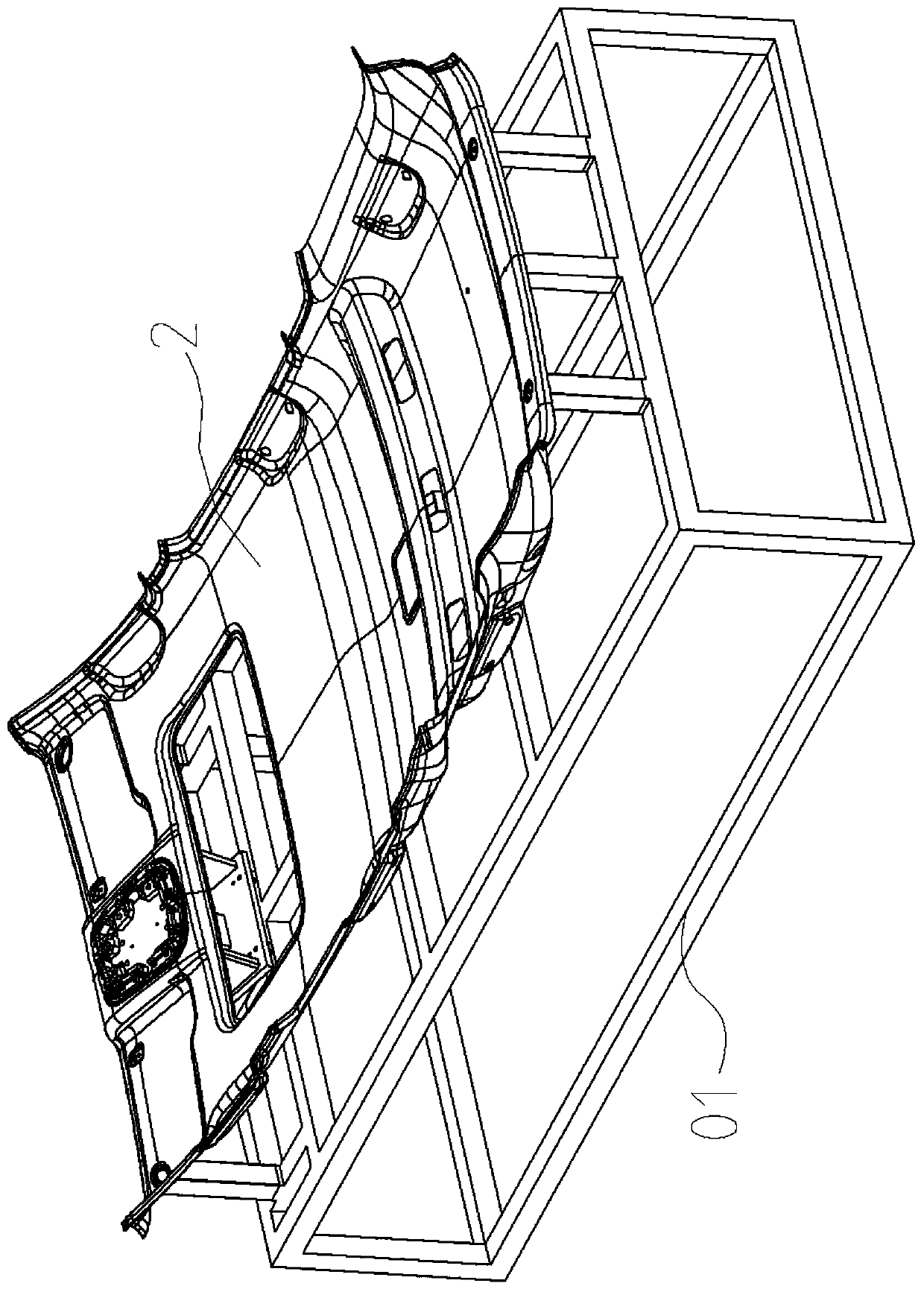

Edge folding tool for front top light support of automotive trim ceiling

A technology for car interiors and lamp brackets, which is applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve the problems of deformation, damage to the ceiling body, and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

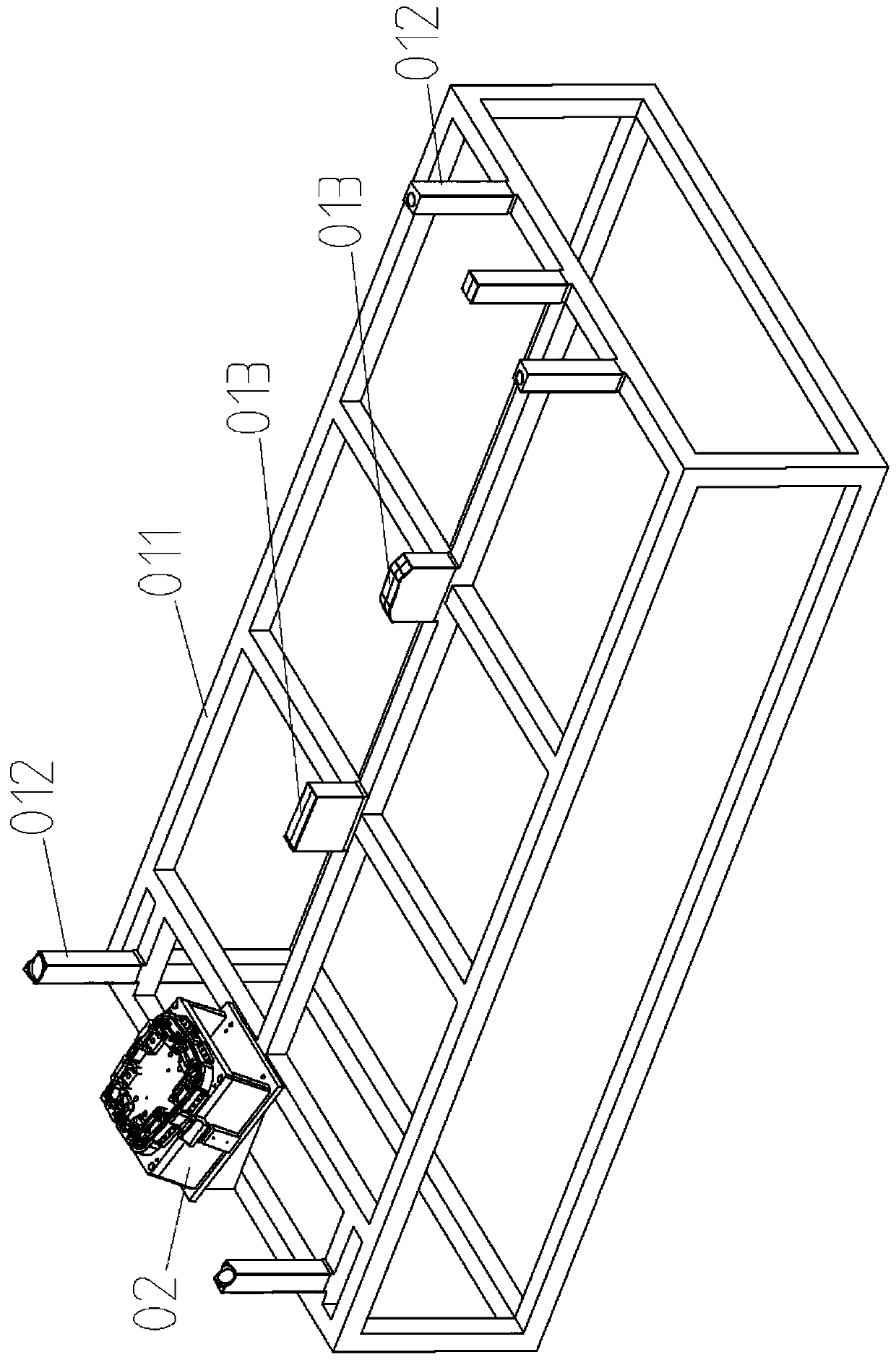

[0027] Including ceiling bracket 01, base 02 and push plate 03. Ceiling bracket 01 comprises base 011, support bar 012 and positioning block 013, and support bar 012 has several and is vertically fixed on the base 011, and positioning block 013 is welded with base 011 and adapts to the depression of ceiling body. The base 02 is located on the base 011 and is bolted to the base 011 through the tripod 04; the upper part of the base 02 is provided with a shaping module 05 and a hemming module 06, and the two sides of the base 02 are provided with ejection modules 07. The base 02 is provided with a through hole through which the push plate 03 can pass, and the push plate 03 can pass through the base 02 and vertically reciprocate. The shaping module 05 is arranged in a ring shape, and the upper surface of the shaping module 05 is provided with a first locking groove 051 for positioning, and the first locking groove 051 is used for positioning the metal frame 1 . The quantity of he...

Embodiment 2

[0031]In order to facilitate the installation of the present invention, the shaping module 05 is composed of a limit block 052 and a support block 053, the number of the support block 053 is the same as that of the hemming module 06, and the limit block 052 and the support block 053 are arranged at intervals. One side of the support block 053 is integrally provided with a connection platform 054 , and the support block 053 is bolted to the base 02 through the connection platform 054 . The bending part of the pressure block 063 is hinged with the support block 053 .

[0032] When installing before use, the support block can be connected to the hemming module first, and then the support block 053 and the hemming module 06 are respectively bolted to the base 02 and the push plate 03; when the support block 053 is connected to the base 02, the Just connect to the top of seat 02. And when one or several of the limiting block 052 and the supporting block 053 are worn, they can be r...

Embodiment 3

[0035] When the metal frame 1 has a certain radian, in order to ensure that the folding angle of the folding module is the same without replacing the connecting rod 062 (that is, the movement track and method during the bending process of the folding 3 are the same), it is necessary to make each pressing Block 063 opens at the same angle. Such as Figure 5 and Figure 10 As shown, in order to adapt to the metal frame 1 bent downwards at both ends, a groove 031 is provided on the push plate 03, and the connecting block is located in the groove 031. In the case of only replacing the shaping module 05 without replacing the connecting rod 062, the depth of the groove is adjusted according to the radian of the metal frame 1, so as to ensure that the turning angle of the hemming module 06 is the same. Because the push plate 03 is cheap, easy to process and easier to disassemble, one or several grooves 031 are processed on the push plate 03 according to the needs, and the depth of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com