Ventilation module for film stretching equipment and such film stretching equipment

A technology of stretching equipment and channels, which is applied in the field of ventilation modules, can solve the problems of the influence of transparency on plastic film web properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

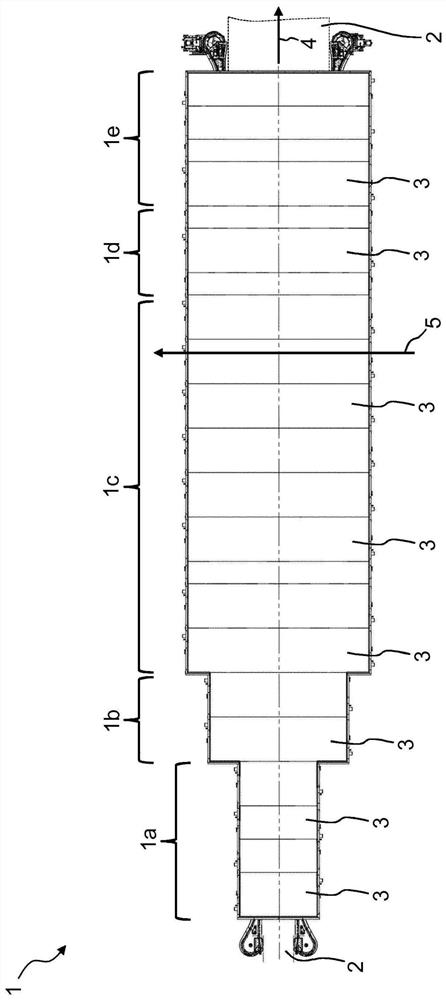

[0040] figure 1 A top view of the film stretching apparatus 1 according to the invention is shown. The film stretching device 1 can be configured as a longitudinal stretching device or a transverse stretching device or a sequential stretching device with longitudinal and transverse stretching stages or as a simultaneous stretching device. The film stretching device 1 is used for stretching the plastic film web 2 and for this purpose is divided, for example, into different zones 1a, 1b, 1c, 1d and 1e. Of course, it is not necessary for all of these regions 1a to 1e to exist in practice. In the different zones 1a to 1e, the plastic film web 2 is subjected to different temperatures in order to generate or set certain film properties. The first zone 1a is also referred to herein as a preheat zone. The second zone 1b is called the stretching zone, and the third zone 1c is called the further heating zone. The fourth zone 1d is also referred to as a neutral zone, and the fifth zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com