Bendable Shaped Batteries

A special-shaped and bending technology, which is applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the problems of increasing the internal resistance of the diaphragm, the impossibility of infiltration of active materials, and the slow ion diffusion rate, so as to improve the ion conductivity and good Effects of electrochemical performance and accelerated diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

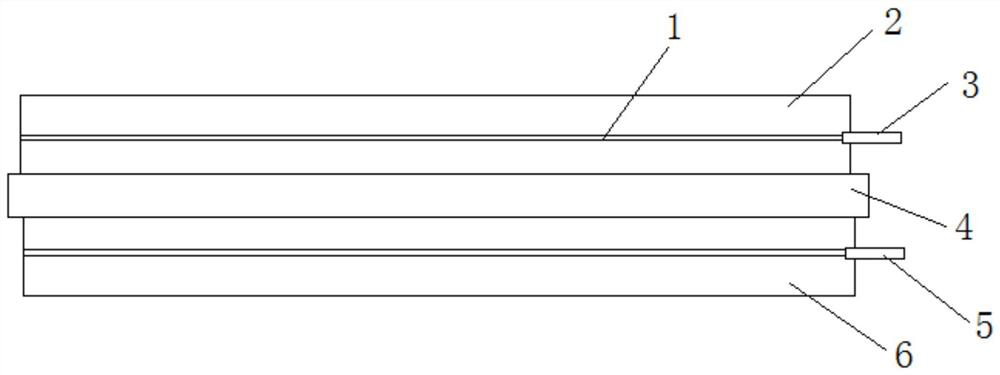

[0035] The bendable special-shaped battery of the present invention includes: a cell structure composed of a diaphragm and a pole piece, an electrolyte filled in the battery structure, and a tab electrically connected to the pole piece, and the pole piece is made of conductive carbon cloth As a current collector, the outer surface of the conductive carbon cloth is provided with active materials;

[0036] The diaphragm is a three-layer structure diaphragm with ion conduction and electronic insulation. The three-layer structure diaphragm is obtained by the following method: soak and soften the commercially available non-woven fabric film in acetic acid, and pass through 50% concentration of sodium chloride at 90°C The solution was soaked for 2 hours, then rinsed with deionized water, and vacuum-dried to obtain a non-woven fiber web; under vacuum conditions, the non-woven fiber web was soaked in a concentration of 0.2 mg / ml of carbon nanotubes prepared with deionized water. In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com