Method for preparing columnar jointing rock sample

A technology for columnar joints and rock samples, which is applied in the field of rock mechanics and engineering, can solve the problems of difficult collection of columnar jointed rock samples and broken joints, and achieve the effects of strong plasticity, strong pertinence, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

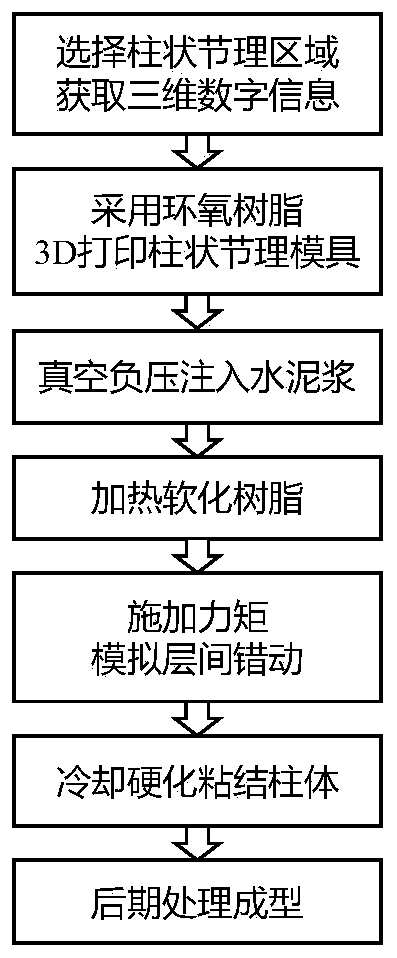

[0025] Such as figure 1 , a method for preparing a columnar jointed rock sample according to the present invention, comprising the following steps:

[0026] S1: Select the area on the rock mass where columnar joints need to be studied, and obtain the three-dimensional digital information of each jointed rock block in the rock mass; the three-dimensional digital information includes the collection of geometric similarity ratio C 1 Similar to bulk density than C Y , to obtain the similarity ratio C of rock mechanical parameters R =C 1 ×C Y , similar to elastic modulus than C E =C 1 ×C Y .

[0027] S2: Use epoxy resin and 3D printing technology to print the columnar joint mold; wherein epoxy resin is added with curing agent and rubber powder.

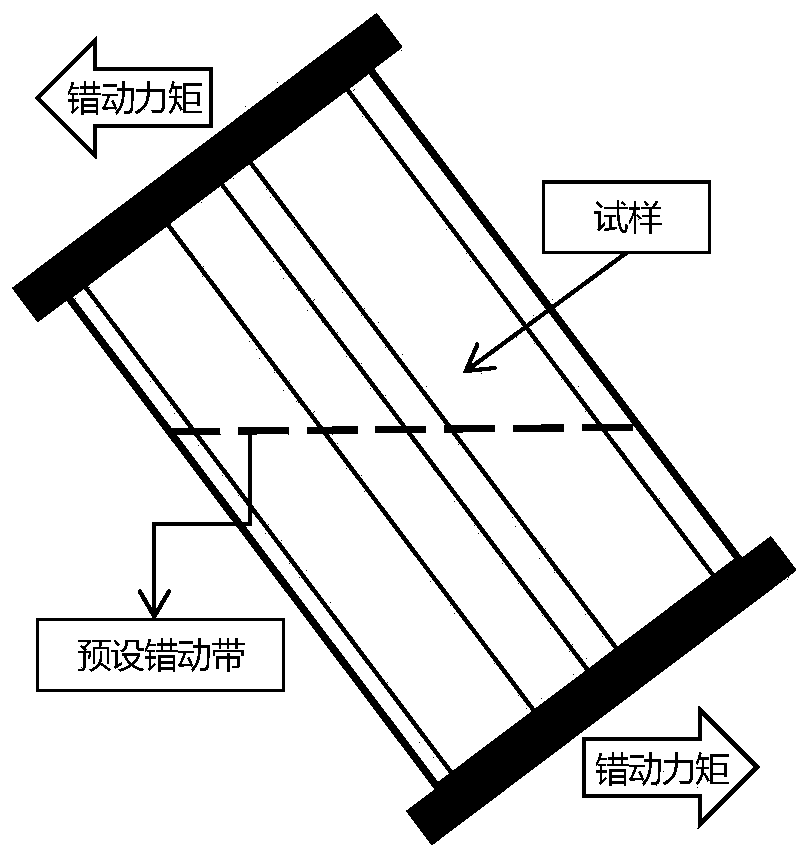

[0028] S3: In a vacuum environment, the cement slurry prepared by cement, standard sand, rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com