Underground gas cut monitoring system based on ultrasonic waves

A monitoring system, ultrasonic technology, applied in the field of oil and gas drilling, can solve the problems of low gas invasion monitoring accuracy and unreliable results, and achieve the effects of reliable and accurate gas invasion data, faster flow velocity, and reduced cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The gas intrusion monitoring during the drilling process of a certain well is taken as an example to introduce. The relevant specific parameters of the well are as follows: well depth 4280m, drill pipe speed 120r / min, drilling fluid density 1.6g / m 3 , displacement 20L / s, gas intrusion gas is CH 4 , The initial viscosity of the drilling fluid is 55Pa·s, the reservoir pressure is 68MPa, the geothermal gradient is 0.0463°C / m, the formation permeability is 50md, and the formation porosity is 30%.

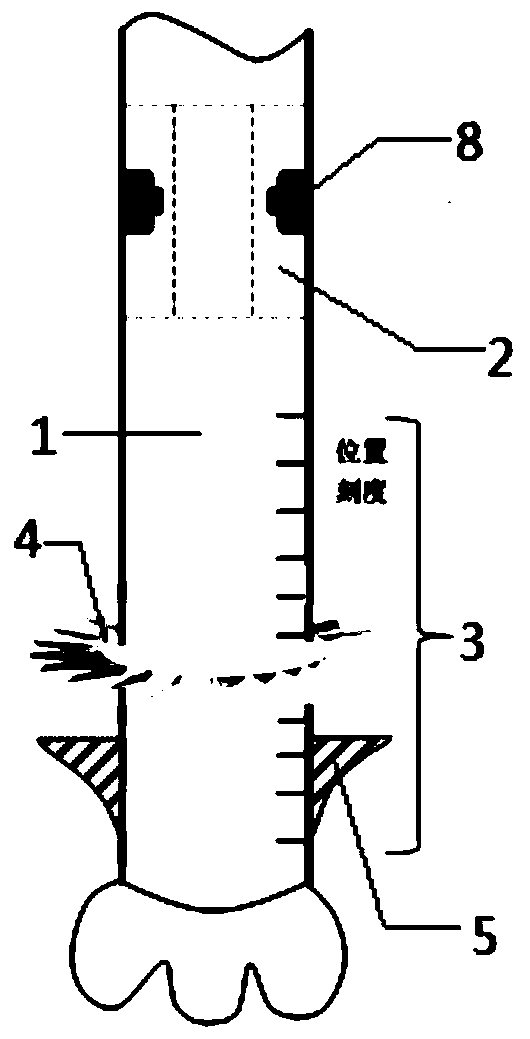

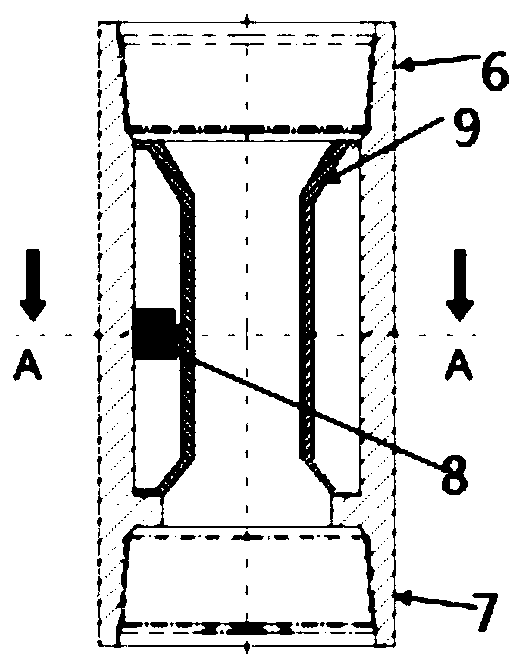

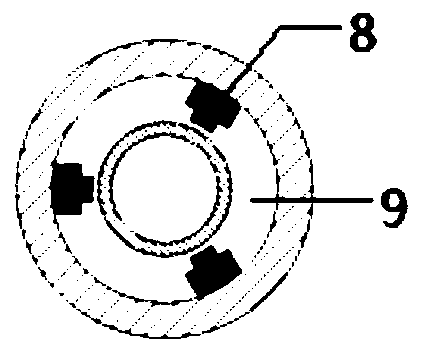

[0029] The ultrasonic-based downhole gas intrusion monitoring system includes an ultrasonic gas intrusion monitoring device 2 fixed on the drill pipe 1, and an annular air-solid separation device 3 located below the ultrasonic air intrusion monitoring device 2. The annular air-solid separation device 3 includes a turbine 4 and a gas-solid pre-separation device 5 fixed on the drill pipe 1 sequentially from top to bottom. The distance between the turbine 4 and the top of the gas-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com