Method for improving acid production rate and conversion rate of butyric acid fermentation

A conversion rate and butyric acid technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of acid production rate and product conversion rate to be improved, and the control is not fine enough, so as to increase the content of butyric acid and conversion rate, cycle shortening, and the effect of increasing acid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

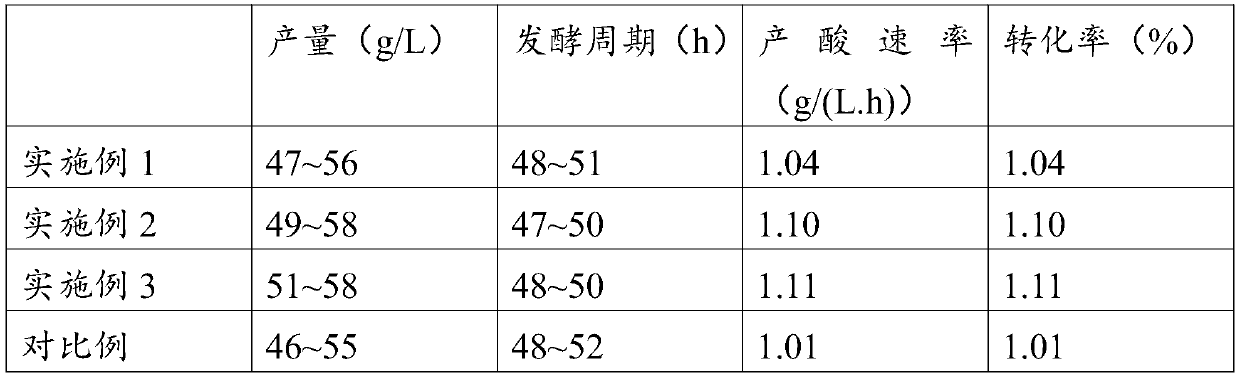

Embodiment 1

[0023] The first-level seed culture process: temperature 37℃, anaerobic, rotation speed 200rpm, natural pH, culture time 20-24h.

[0024] The ORP value is changed by passing sterile air into the seed tank (the amount of sterile air is 5% of the volume of the material), and the fermentation tank is not allowed to pass sterile air for normal culture, that is, the ORP is -400~- for secondary seed culture. 200, temperature 37℃, rotation speed 200rpm, culture period 18h. During fermentation, the ORP is -600~-300, the temperature is 37℃, the speed is 200rpm, the culture period is 48-51h, and the pH is controlled at 5.90. After the fermentation, the butyric acid content was determined.

[0025] For primary seed culture and secondary seed culture, the seed growth medium used is: glucose 20g / L, yeast extract 2g / L, peptone 4g / L, (NH 4 ) 2 SO 4 2g / L, K 2 HPO 4 1g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O 0.1g / L, FeSO 4 ·7H 2 O 0.015g / L, CaCl 2 ·2H 2 O 0.015g / L, MnSO4·H 2 O 0.01g / L, CoCl 2 ·6H 2 O...

Embodiment 2

[0029] The seed tank is cultured normally, and the sterile air is passed into the fermentor to change the ORP value (the amount of sterile air is 8% of the material volume), that is, the ORP of the secondary seed culture is -500~-300, the temperature is 37°C, and the rotation speed 200rpm, 18h culture period, pH control at 5.90. The ORP of fermentation culture is -450~-350, the temperature is 37℃, the rotation speed is 200rpm, the culture period is 49h, and the pH is controlled at 5.90. After the fermentation, the butyric acid content was determined.

Embodiment 3

[0031] Sterile air is introduced separately (the amount of sterile air in the seed tank is 5% of the volume of the material, and the amount of sterile air in the fermenter is 8% of the volume of the material), that is, the ORP of secondary seed culture is- 400~-200, speed 200rpm, culture period 18h, pH control at 5.90. The ORP of fermentation culture is -450~-350, the temperature is 37℃, the rotation speed is 200rpm, the culture period is 49h, and the pH is controlled at 5.90. After the fermentation, the butyric acid content was determined.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com