A device and method for efficient oxidation of waste lye with fractal distribution of large and small bubbles

A gas distribution device and waste lye technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as incorrect methods and ideas, difficulties, oxygen escape, etc. Achieve the effect of uniform temperature in the cross-section of the device, enhanced mass transfer and heat transfer, and improved oxygen mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

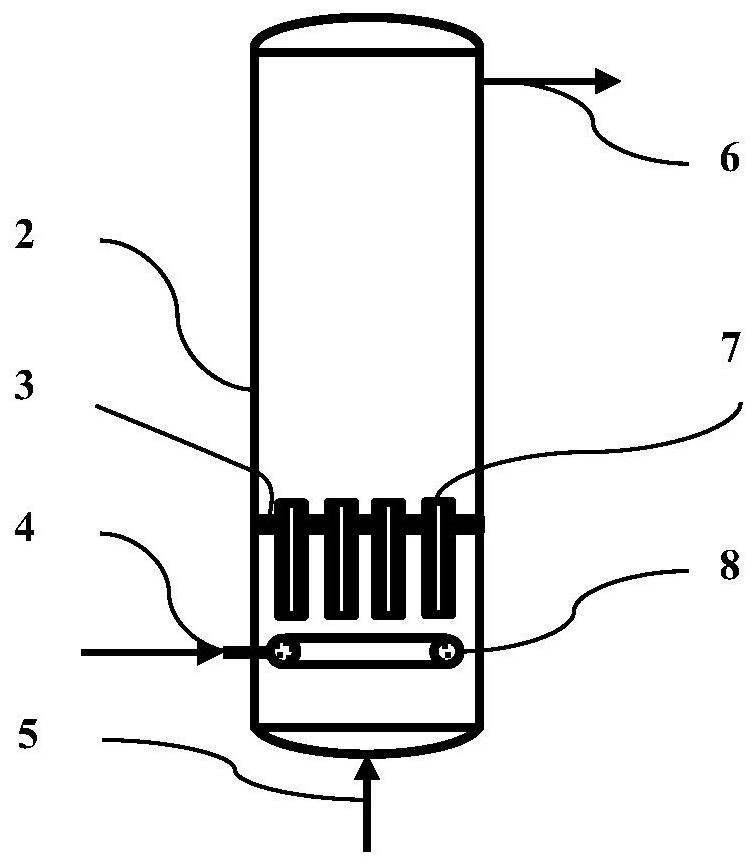

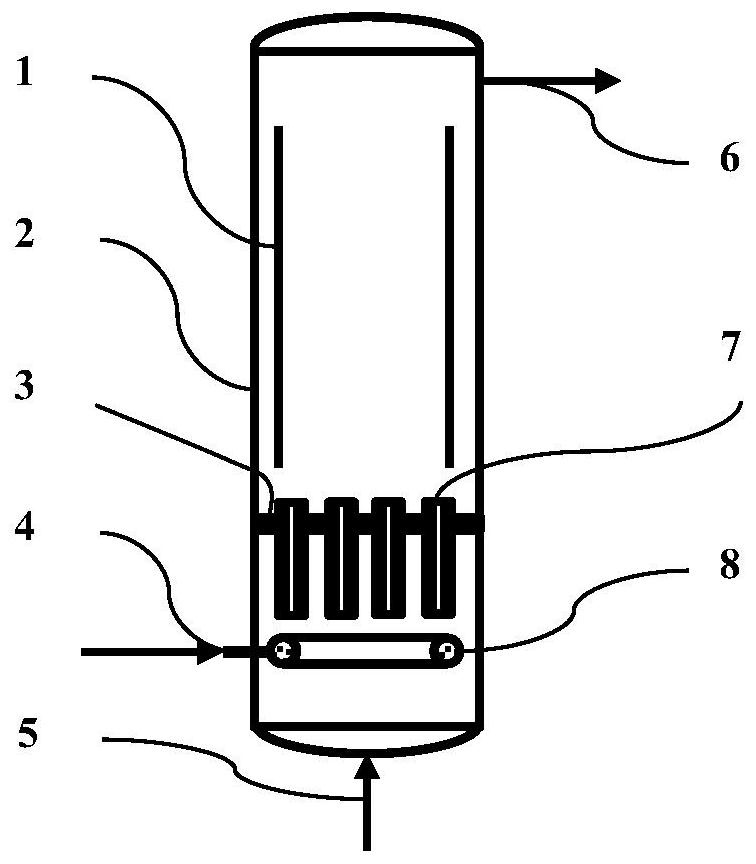

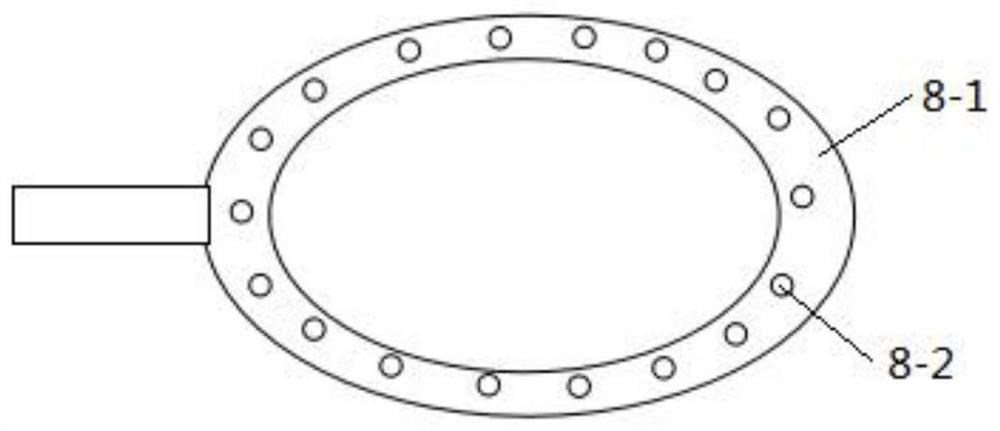

[0093] The invention provides a device for efficient oxidation of waste lye with fractal distribution of large and small bubbles, see figure 1 , including the outer cylinder 2, the interior of the outer cylinder 2 is provided with a first separator 3, and the first separator 3 is fixed with more than one first burster 7 for contacting the gas phase and the liquid phase, the first burster 7 and the separator The plates are connected by flanges or welded seals. The bottom of the outer cylinder 2 is provided with a liquid phase inlet 5, a first gas distribution device 8 for distributing the gas phase is provided below the first burster 7, and a first gas phase inlet 4 is provided on the side of the outer cylinder 2 to communicate with the first gas distribution device. 8. The first gas phase inlet 4 and the liquid phase inlet 5 are located under the first partition 3. The first gas phase inlet 4 is higher than the liquid phase inlet 5 to facilitate the entry of gas and liquid res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com