Dedicated collection barrel for waste masks

A technology for special collection and masks, applied in the field of special collection buckets for discarded masks, can solve the problems of complex structure, reduced transmission, and it is difficult to push into the trash can, and achieves the effect of increasing the storage capacity and improving the sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention, and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

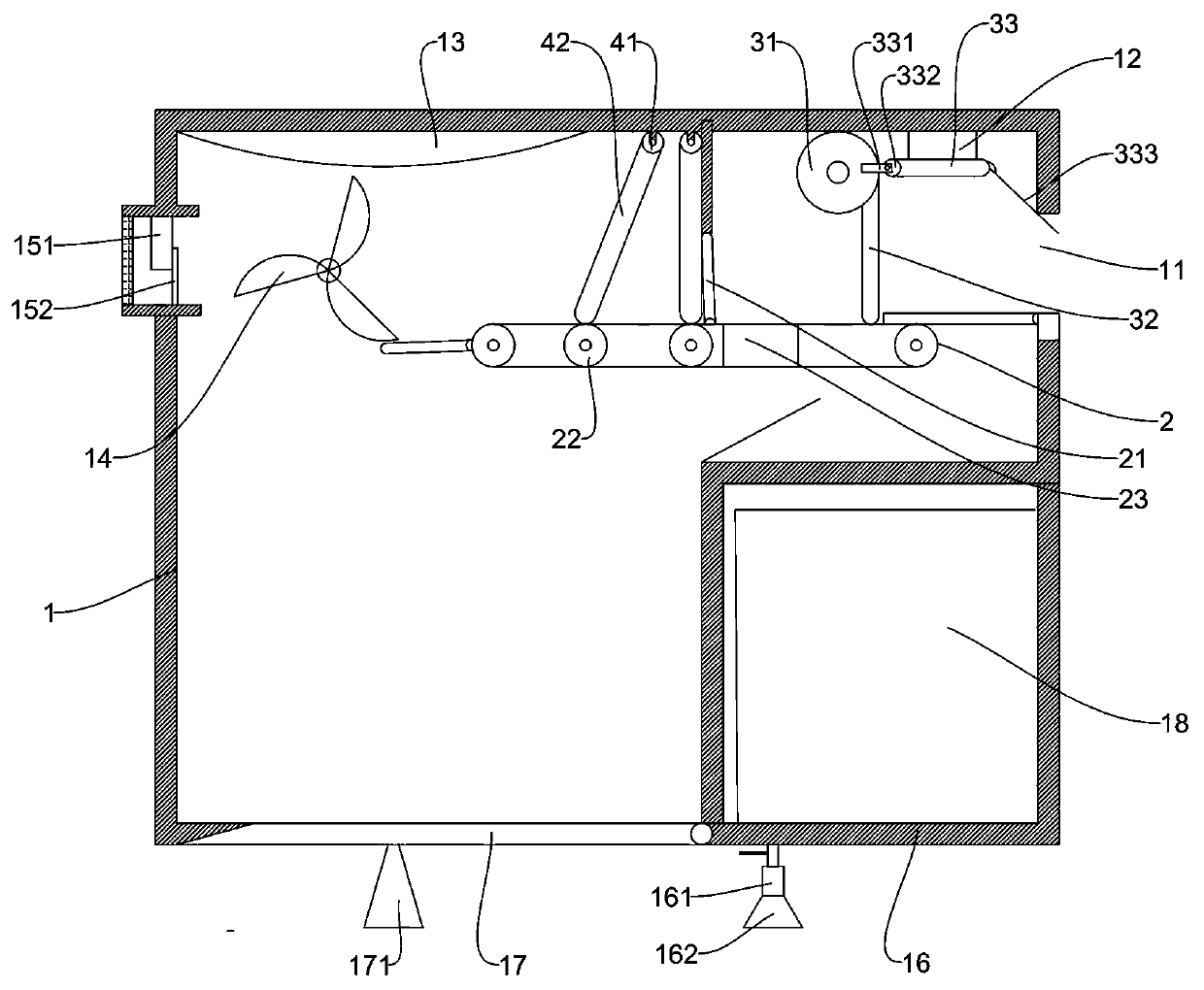

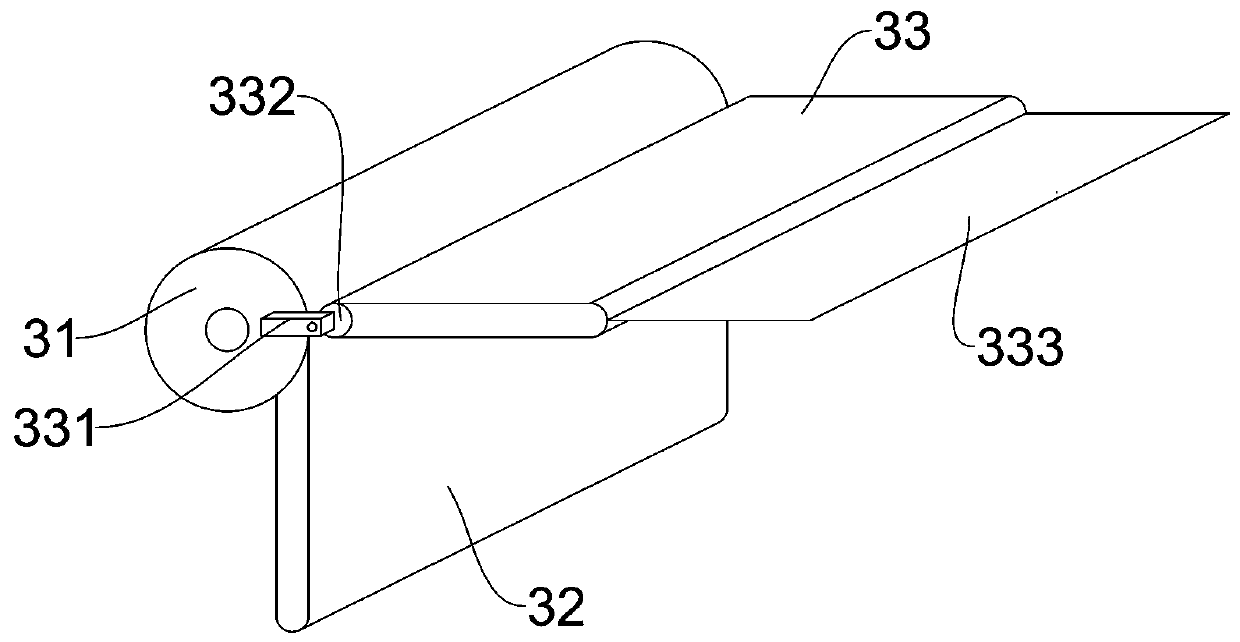

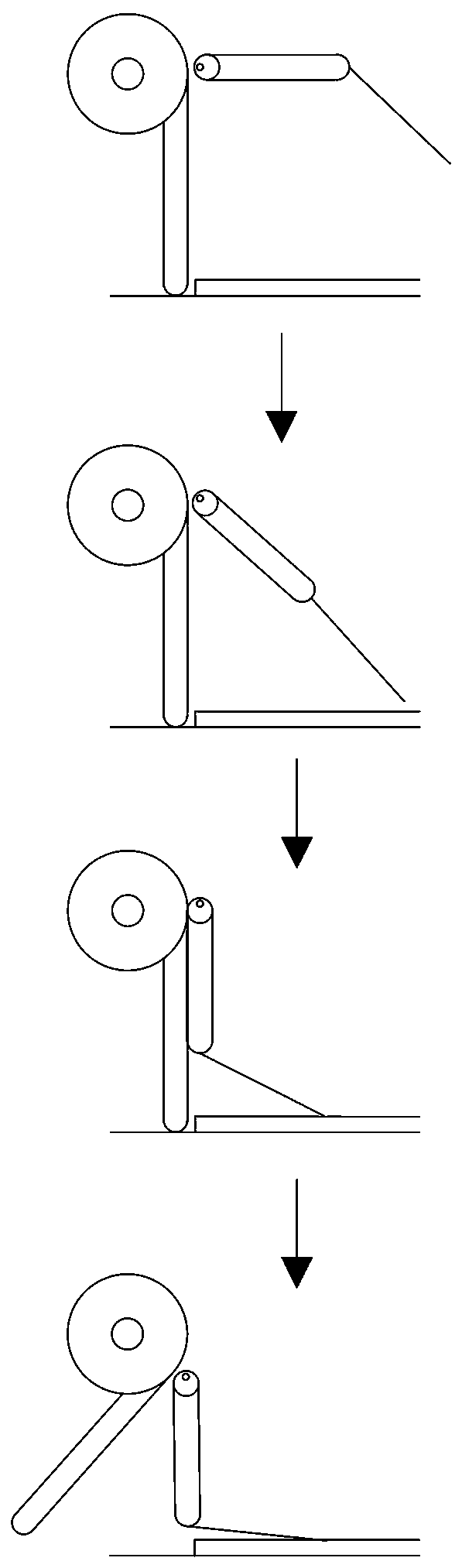

[0028]A special collection barrel for waste masks, such as figure 1 As shown, it includes a barrel body 1 and a collection port 11 arranged on the side of the barrel body 1. The collection port 11 is provided with a conveyor belt 2 for sending garbage into the barrel body 1. The collection port 11 is also provided with a sensor for sensing garbage. The sensor is electrically connected with the motor that drives the conveyor belt 2 transmission wheels to rotate. This sensor can be the infrared emitter that is arranged on one end of the solid part of the side edge of the collection port 11 and the receiver that is arranged at the other end for receiving the infrared rays that it sends out. When garbage is thrown on the conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com