Pressing machine for red wine corks

A technology of oak cork and red wine, which is applied in forming/shaping machines, wood processing appliances, special molding/shaping machines, etc., can solve the problems of troublesome and laborious operation, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

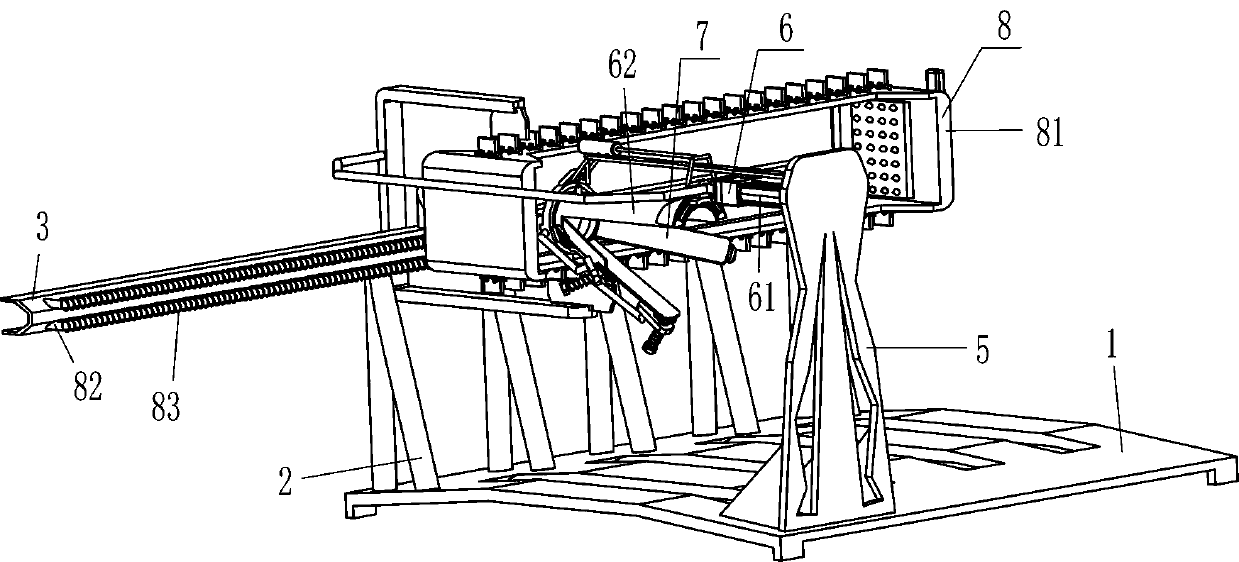

[0022] refer to Figure 1-Figure 5 , a red wine cork pressing machine, including a base 1, a support rod 2, a horizontal plate 3, an L-shaped rod 4, a support plate 5, a cutting mechanism 6 and a guiding mechanism 7, and the rear side of the base 1 top is uniformly spaced and fixed There are support rods 2, a horizontal plate 3 is fixedly connected between the tops of all the support rods 2, an L-shaped rod 4 is fixed in the middle of the top of the horizontal plate 3, and a support plate 5 is fixedly connected to the front left part of the top of the base 1, and the rear of the support plate 5 The upper part of the side is provided with a cutting mechanism 6, the cutting mechanism 6 cooperates with the L-shaped bar 4, and the lower part of the cutting mechanism 6 is provided with a guide mechanism 7.

[0023] The cutting mechanism 6 includes an electric push rod 61, a round head cutter cylinder 62, an L-shaped support 63, an annulus 64, a roller 65, a first spring 68 and an a...

Embodiment 2

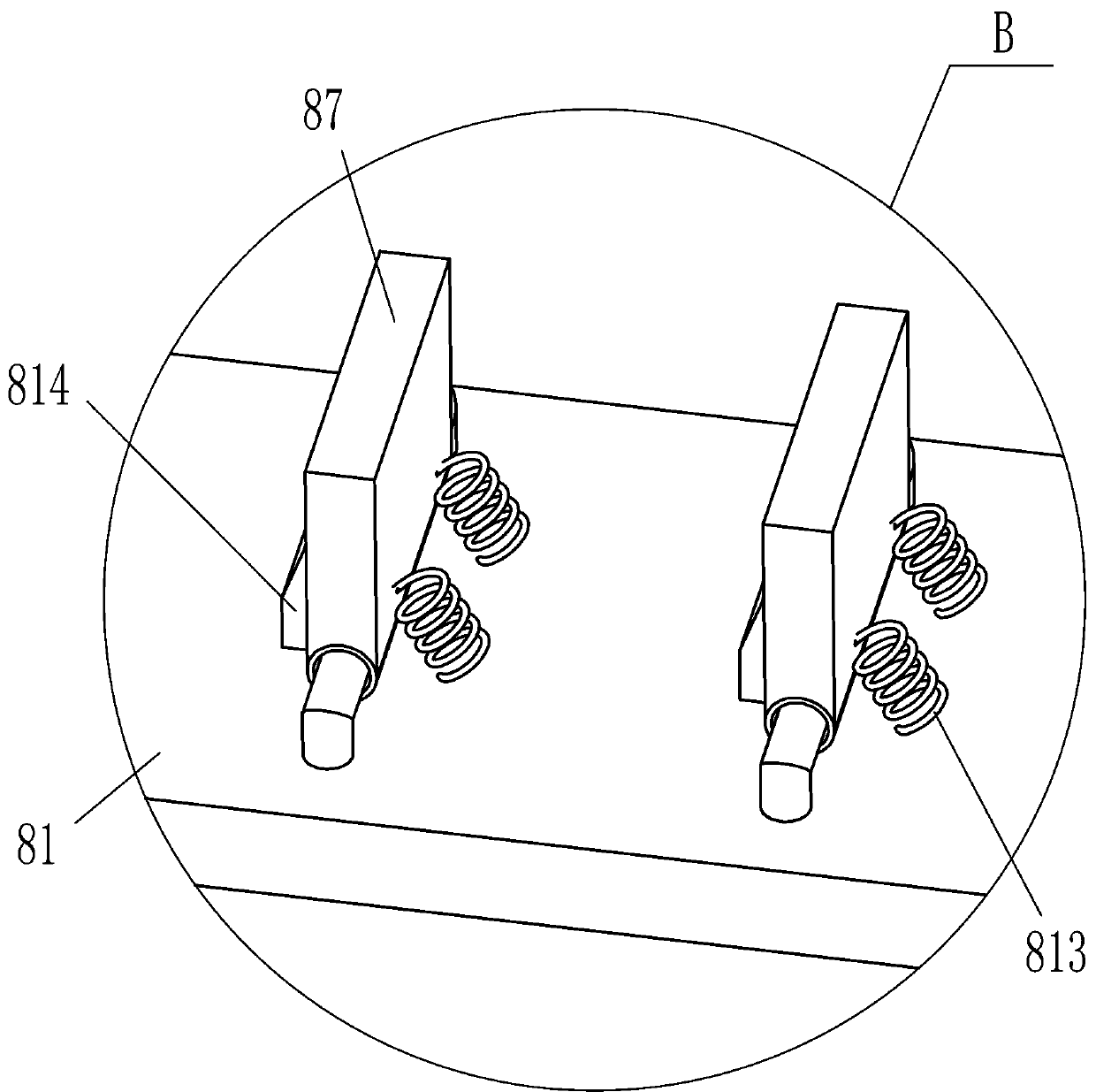

[0029] refer to figure 1 , figure 2 , Figure 4 and Figure 6 , a kind of red wine cork pressing machine, embodiment is compared with embodiment 1, and main difference is that in this embodiment, also includes pusher mechanism 8, and pusher mechanism 8 includes back-type placement frame 81, u-shaped bar 82, the first Three springs 83, u-shaped connecting rod 84, u-shaped plate 85, clamping plate 86, swing plate 87, the fourth spring 88, pull plate 89, splint 810, sliding sleeve 811, u-shaped guide rod 812, the fifth spring 813, Limiting block 814 and fixed plate 815, the upper and lower sides of the front side of horizontal plate 3 are fixedly connected with u-shaped bar 82, and the sliding type on u-shaped bar 82 is provided with two sliding sleeves 811, four sliding sleeves 811 front sides Fixedly connected with fixed plate 815, the front side of fixed plate 815 is fixedly connected with return type placement frame 81, and the middle of the outer top of return type place...

Embodiment 3

[0032] refer to figure 2 Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that in this embodiment, it also includes a guide oblique rod 9, a movable rod 10, a sixth spring 11 and a contact plate 12, and the lower circumference of the outer surface of the ring 64 To the evenly spaced ones, there are guide oblique rods 9 corresponding to the swinging arc-shaped plates 71; 71 buffered contact plate 12, the contact plate 12 is in contact with the swing arc plate 71, and the sixth spring 11 is wound between the outer end of the movable rod 10 and the outer surface of the guide inclined rod 9.

[0033] Also include cylinder 13, mounting rod 14 and jet pipe 15, arc slide block 69 tops are fixedly connected with mounting rod 14, L-shaped support 63 passes mounting rod 14, and cylinder 13 is installed on the rear side of L-shaped support 63 outer top, The telescoping link of cylinder 13 is fixedly connected with mounting rod 14 rear side tops, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com