Novel steel structure and preparation method thereof

A steel structure, a new type of technology, applied in the direction of building structure, construction, etc., can solve the problems of self-heavy, unfavorable production, etc., achieve the effect of light weight, save manufacturing cost, and improve the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The present invention provides following two kinds of feasible preparation techniques:

[0070] The preparation method of the first novel steel structure comprises the following steps:

[0071] (1) Cutting plate-shaped substrates:

[0072] The plate-shaped base material is a flat steel material such as a steel plate or a flat steel, or the plate-shaped base material is a flat steel material obtained by straightening and slitting a wide-band steel, or, the plate-shaped base material is Different diameter steel plate or different diameter flat steel.

[0073] cutting transversely along the cutting line on the plate-shaped base material to obtain a first plate body and a second plate body interlocking with each other;

[0074] Wherein, the first plate body is formed with a plurality of first protrusions arranged at intervals at the cutting position, and a first concave portion is formed between any two adjacent first protrusions; the second plate body is cut A plurality...

Embodiment 1

[0089] Such as Figure 1 to Figure 10 Shown, the preferred structure of a kind of novel just structure described in the present invention.

[0090] Such as Figure 4 As shown, the novel steel structure described in this embodiment is an I-shaped steel with an I-shaped cross section. The novel rigid structure includes a web 40 and flanges 50 located at both ends of the web 40 . The web 40 is a hollowed out long straight steel plate.

[0091] In one embodiment, the flange 50 and the web 40 are integrally formed by a rolling process; in another embodiment, the flange 50 and the web 40 are connected by welding.

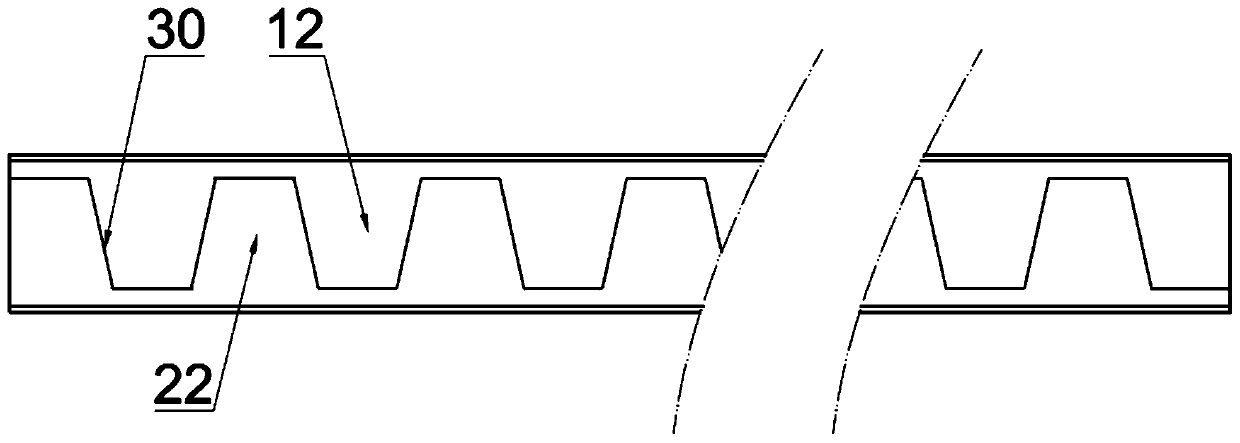

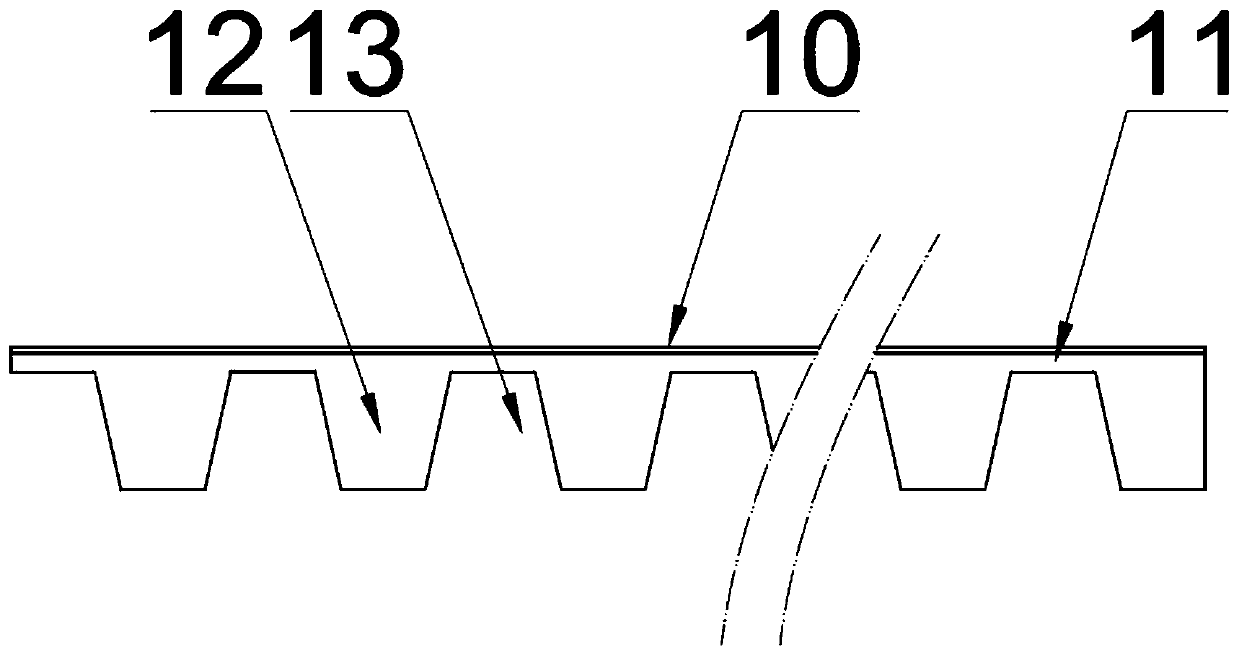

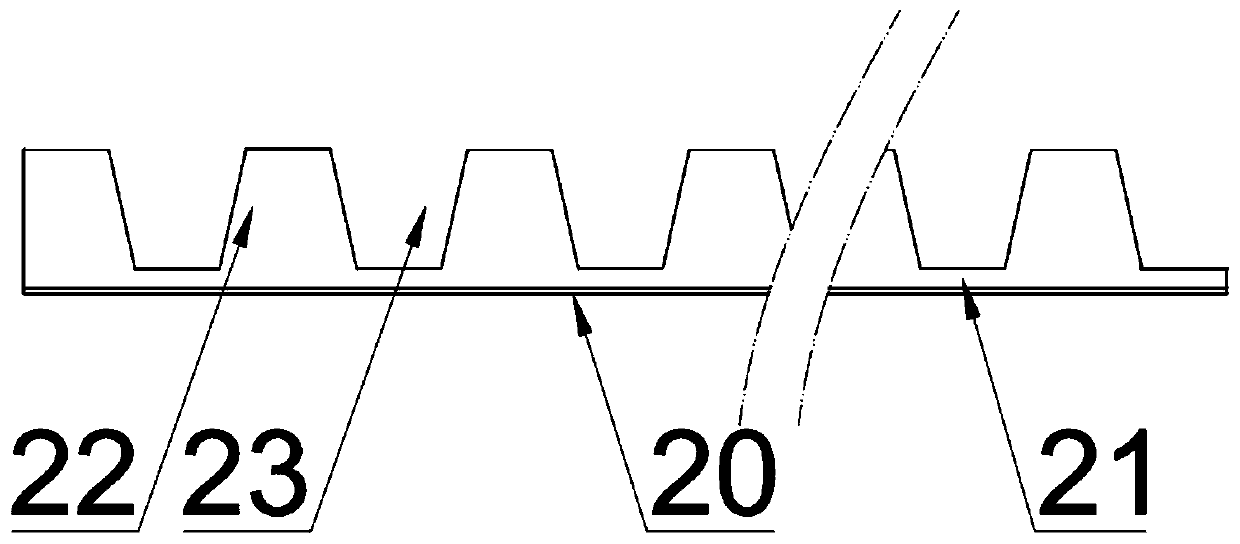

[0092] Specifically, the web 40 is a combined steel plate, and the web 40 includes a first plate body 11 and a second plate body 21 that can be engaged with each other, and the first plate body 11 and the second plate body 21 are welded to form a long straight plate .

[0093] Such as figure 2 As shown, the first plate body 11 has a plurality of first protrusions 1...

Embodiment 2

[0148] A new type of steel structure and its preparation method in this embodiment 2 are consistent with the structure and method of embodiment 1, and this embodiment 2 provides a preferred structural size of a new type of steel structure.

[0149] Such as Figure 11 As shown, the top length L1 of the first convex portion and the second convex portion of the web is 100 mm to 200 mm. Under this structural dimension, the length of the contact surface between the first convex part and the second convex part is 100 mm to 200 mm. Correspondingly, the root length L2 of the first convex portion and the second convex portion is 120mm˜200mm.

[0150] Preferably, the length L1 of the top of the first protrusion and the second protrusion is 100 mm or 120 mm.

[0151] Such as Figure 11 As shown, the heights H1 of the first convex portion and the second convex portion are both 100 mm to 200 mm. Preferably, the height H2 of the first convex portion and the second convex portion are bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com