Garbage collection device for urban drain

A garbage collection and drainage ditch technology, which is applied to water supply devices, drainage structures, grease/oily substances/floating matter removal devices, etc., can solve problems such as clogging in narrow and small drainage ditches, and achieve the effect of increasing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

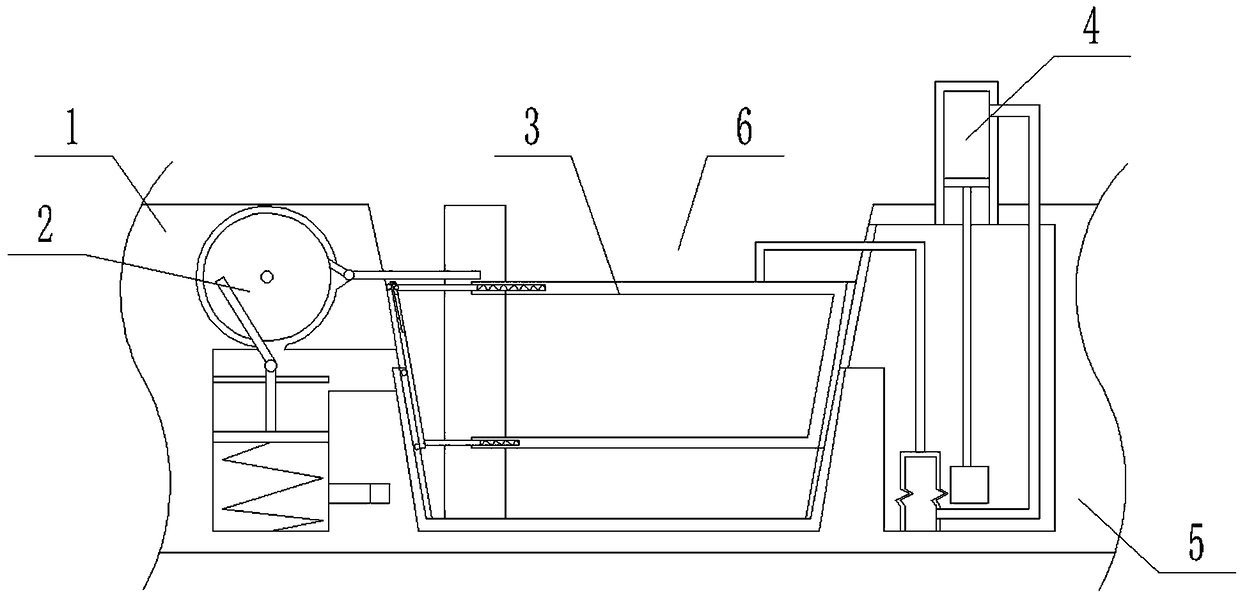

Specific implementation one:

[0035] Combine below figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 illustrate this embodiment, the present invention relates to a garbage collection device, more specifically a garbage collection device for urban drainage ditch, including The left wall 1, cleaning device 2, blocking device 3, lifting device 4, right wall 5, and drainage ditch 6 can not only block the garbage in the drainage ditch, but also the filter device II can automatically rise according to the height of the water level, increasing the The overall height of the unit to prevent debris from drifting over the unit from the upper end of the unit.

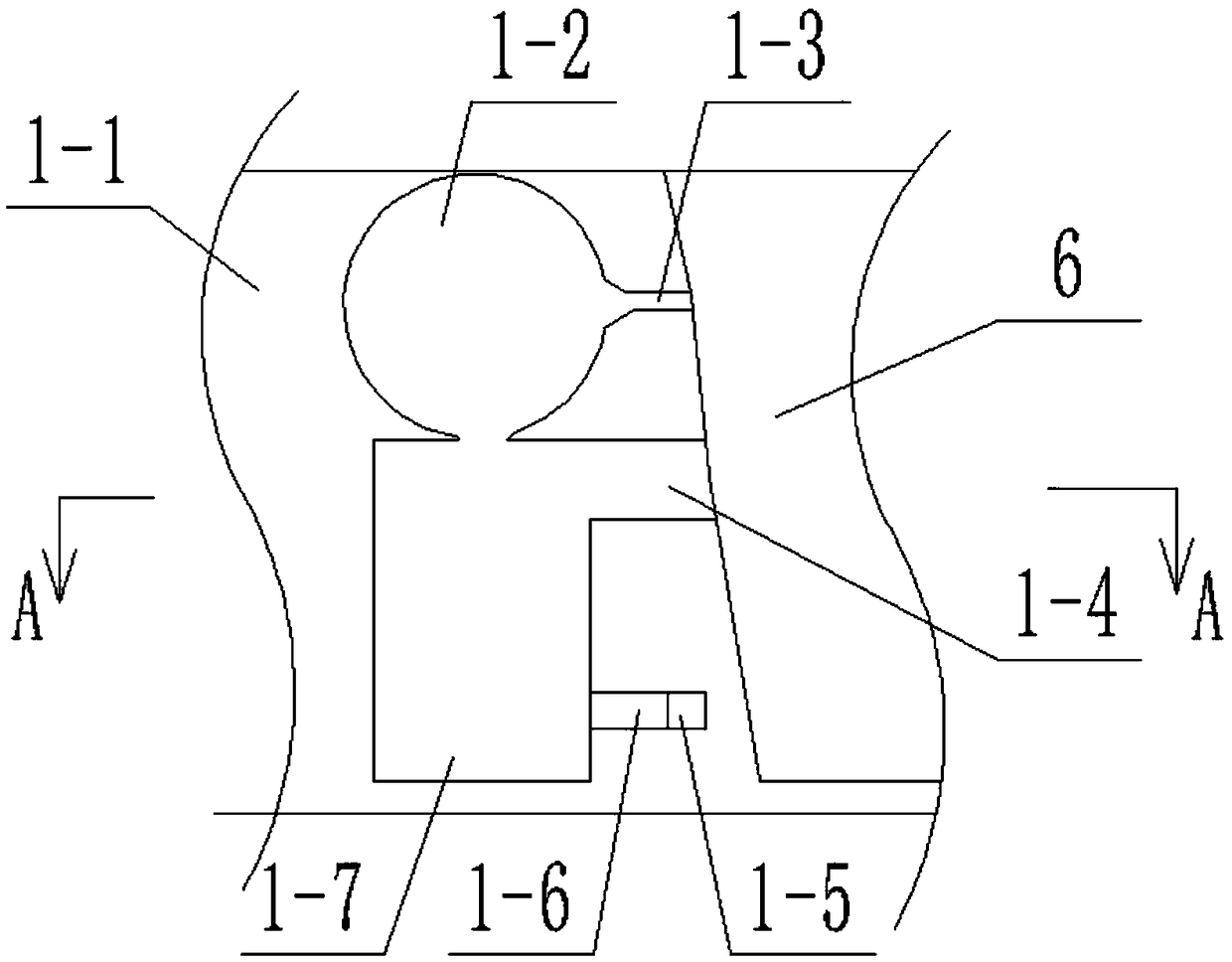

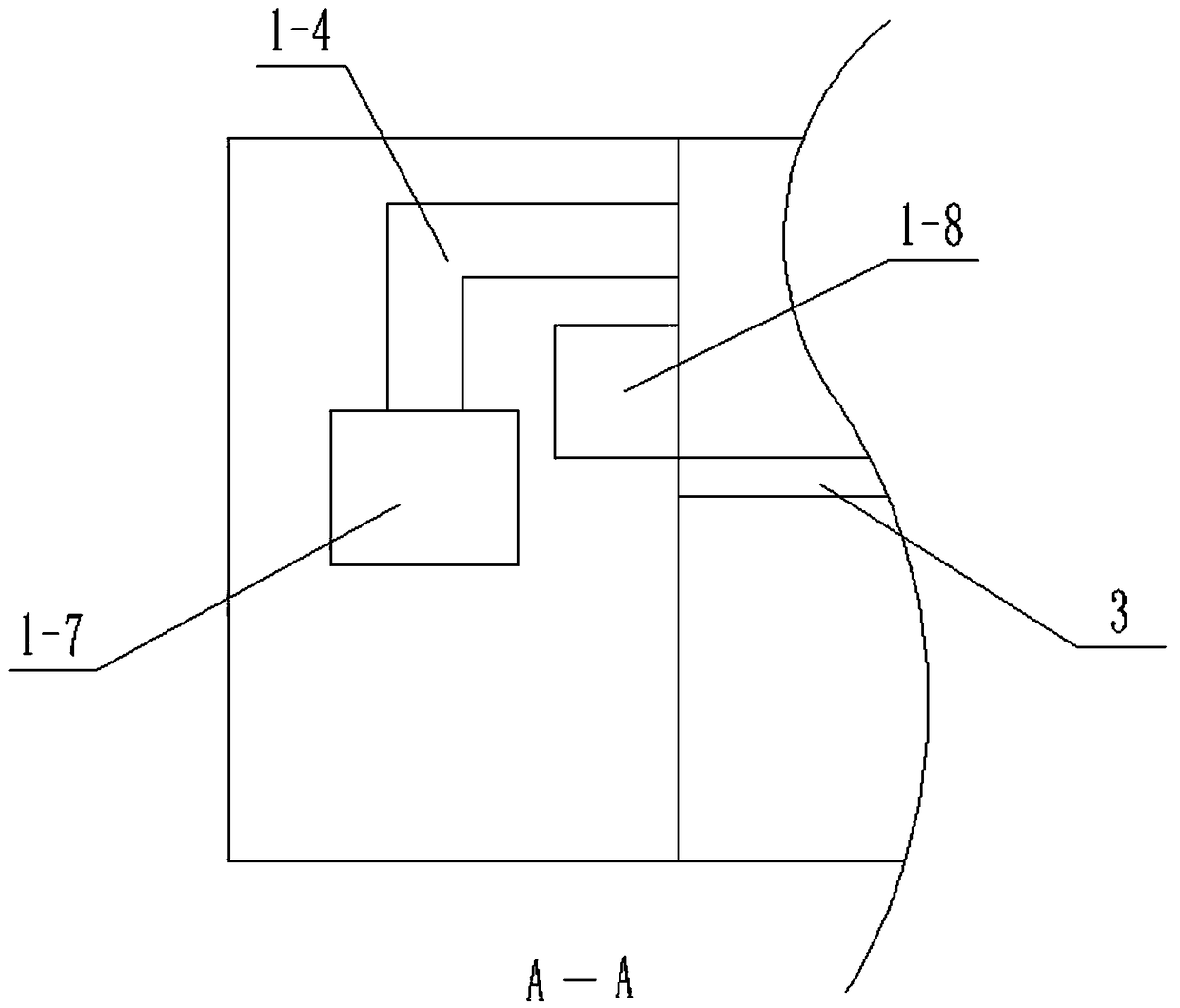

[0036] The left wall 1 consists of a left retaining wall 1-1, a circular groove 1-2, a horizontal groove I1-3, a horizontal groove II1-4, an auxiliary drainage groove 1-5, a communication groove 1-6, and a vertical groove 1- 7; the circular groove 1-2 is arranged on the inner upper end of the left retaining wall 1-1; the left end of...

Example Embodiment

Specific implementation two:

[0045] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 describe this embodiment. This embodiment further describes Embodiment 1. The lower baffle 2-7 and the upper baffle 2-9 When the gap between them is communicated with the communication grooves 1-6, the upper baffle plate 2-9 is located in the vertical grooves 1-7.

Example Embodiment

Specific implementation three:

[0046] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, and 12 describe this embodiment. This embodiment further describes Embodiment 1. The upper baffle 2-9 and the lower baffle 2-7 When both are located in the vertical grooves 1-7, the total weight of the water stored between the upper baffle 2-9 and the lower baffle 2-7 is greater than the elastic force of the spring I2-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com