Automatic laser device

A laser and laser head technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as harm to health, pollution, and dust generation, and achieve the effects of reasonable layout, stable structure, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

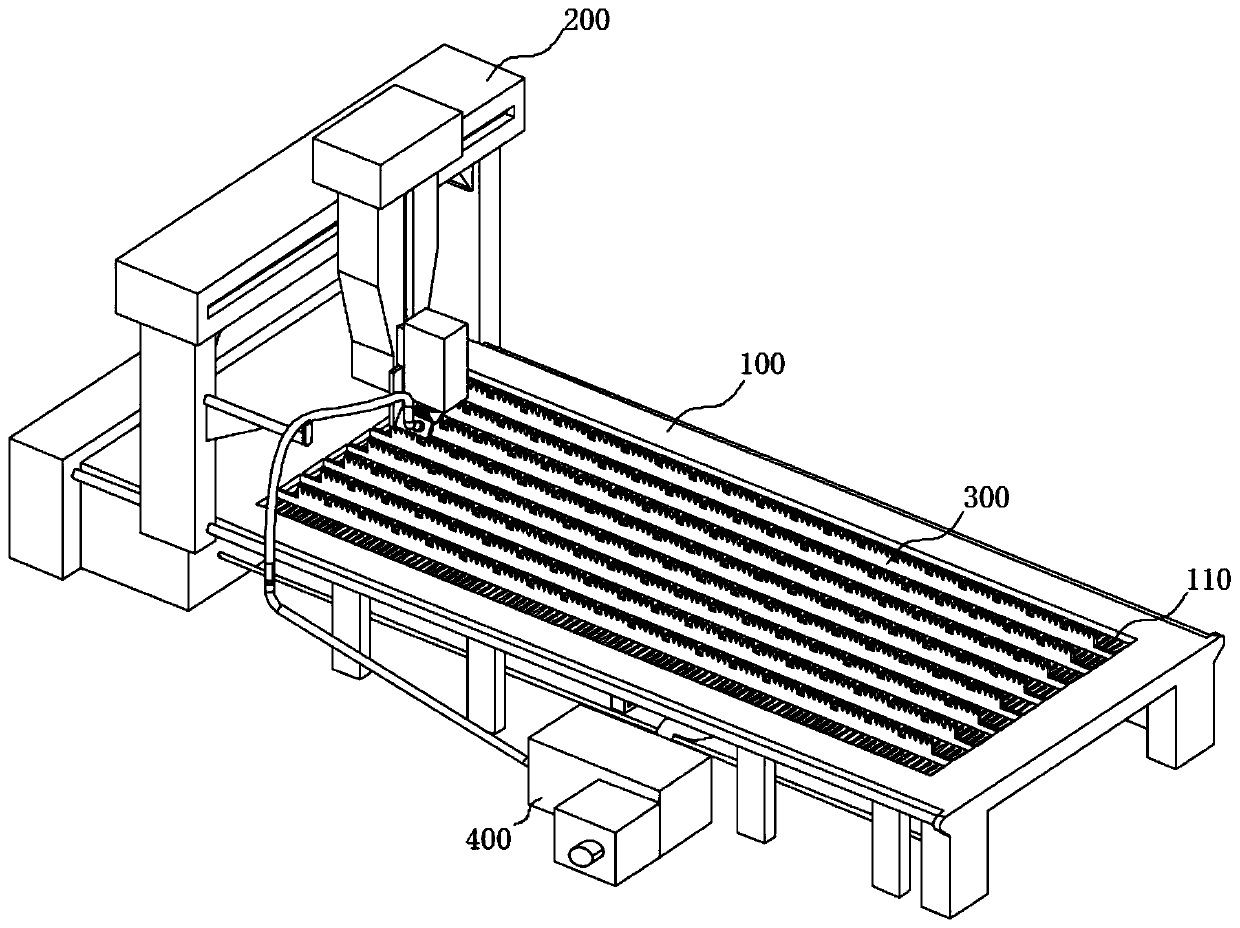

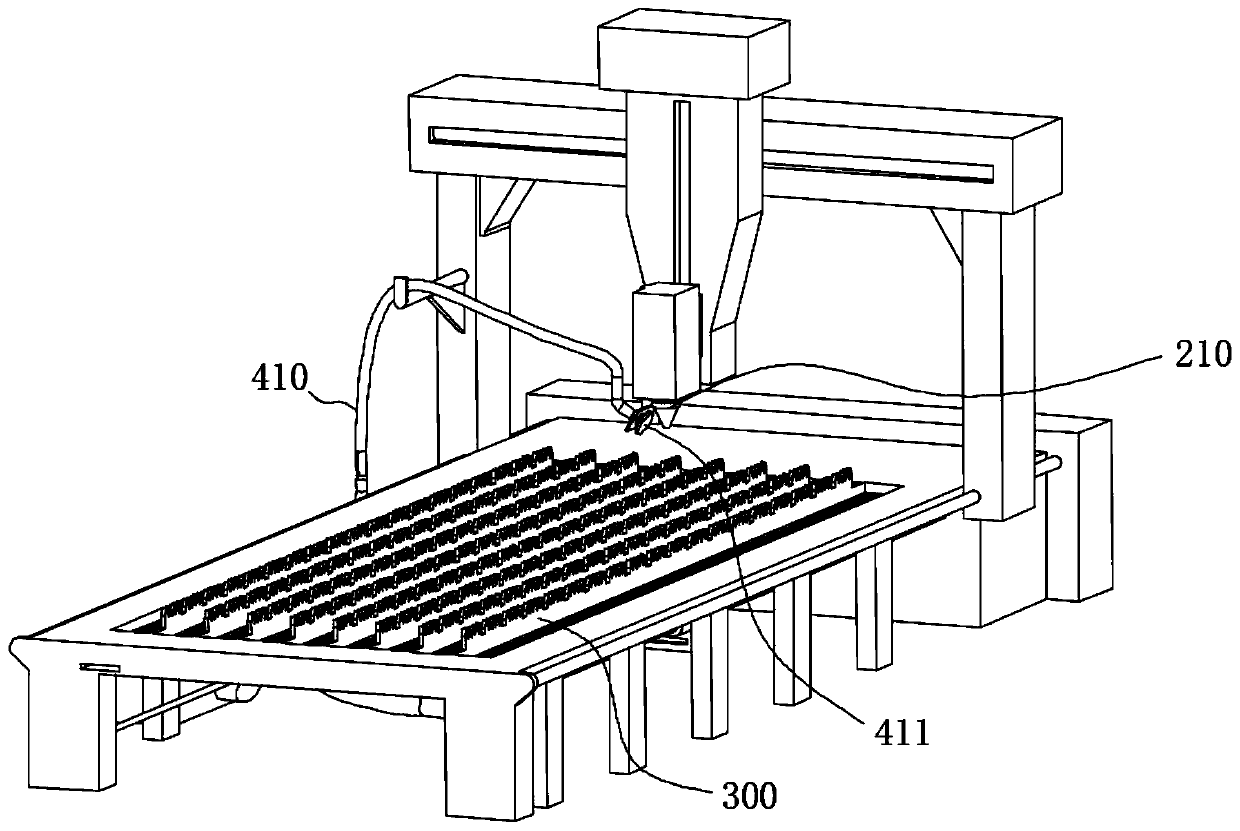

[0022] refer to Figure 1-4 , a kind of automatic laser device is proposed in the present embodiment, it is characterized in that: comprise processing platform 100, the laser mechanism 200 of gantry type is housed on processing platform 100, also is equipped with suction mechanism 400 on processing platform 100, suction mechanism 400 is arranged corresponding to the laser mechanism 200, and the suction mechanism 400 is used to absorb exhaust gas, dust and debris generated when the laser mechanism 200 cuts workpieces.

[0023] Through the setting of the air suction mechanism 400, the exhaust gas, dust and debris generated by the laser mechanism 200 cutting the workpiece can be absorbed, so as to avoid polluting the working environment, and is environmentally friendly and reliable.

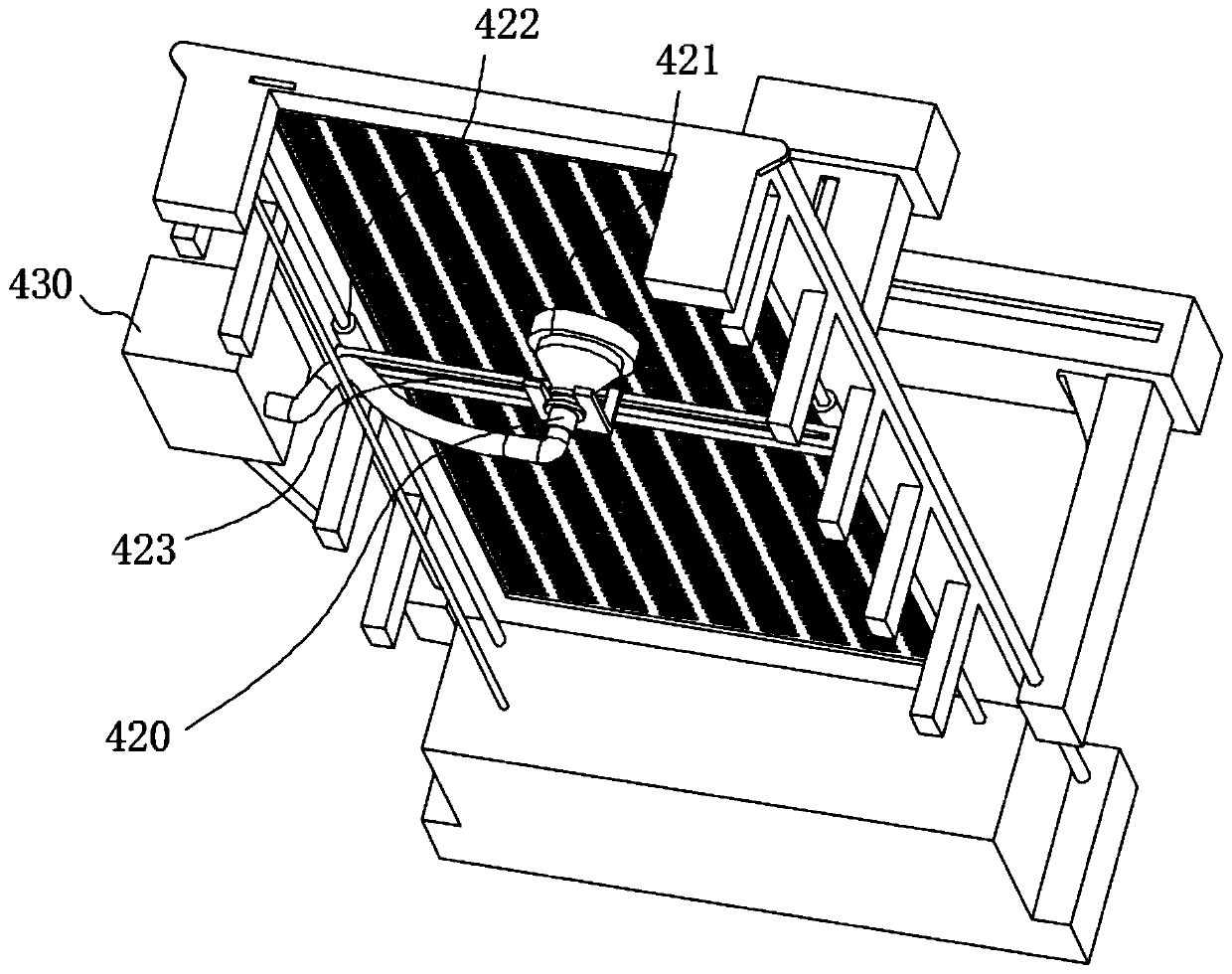

[0024] The suction mechanism 400 includes an A suction assembly 410 and a B suction assembly 420. The A suction assembly 410 is arranged on the upper side of the workpiece for absorbing exhaust gas,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com