Stamping die for facilitating waste discharge

A technology for stamping dies and waste materials, which is applied in the field of stamping dies that facilitate the discharge of waste materials. It can solve the problems of unsatisfactory automatic production, low cleaning efficiency, and high risk factor of operation, so as to improve operation safety, high work efficiency, and convenient and fast operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

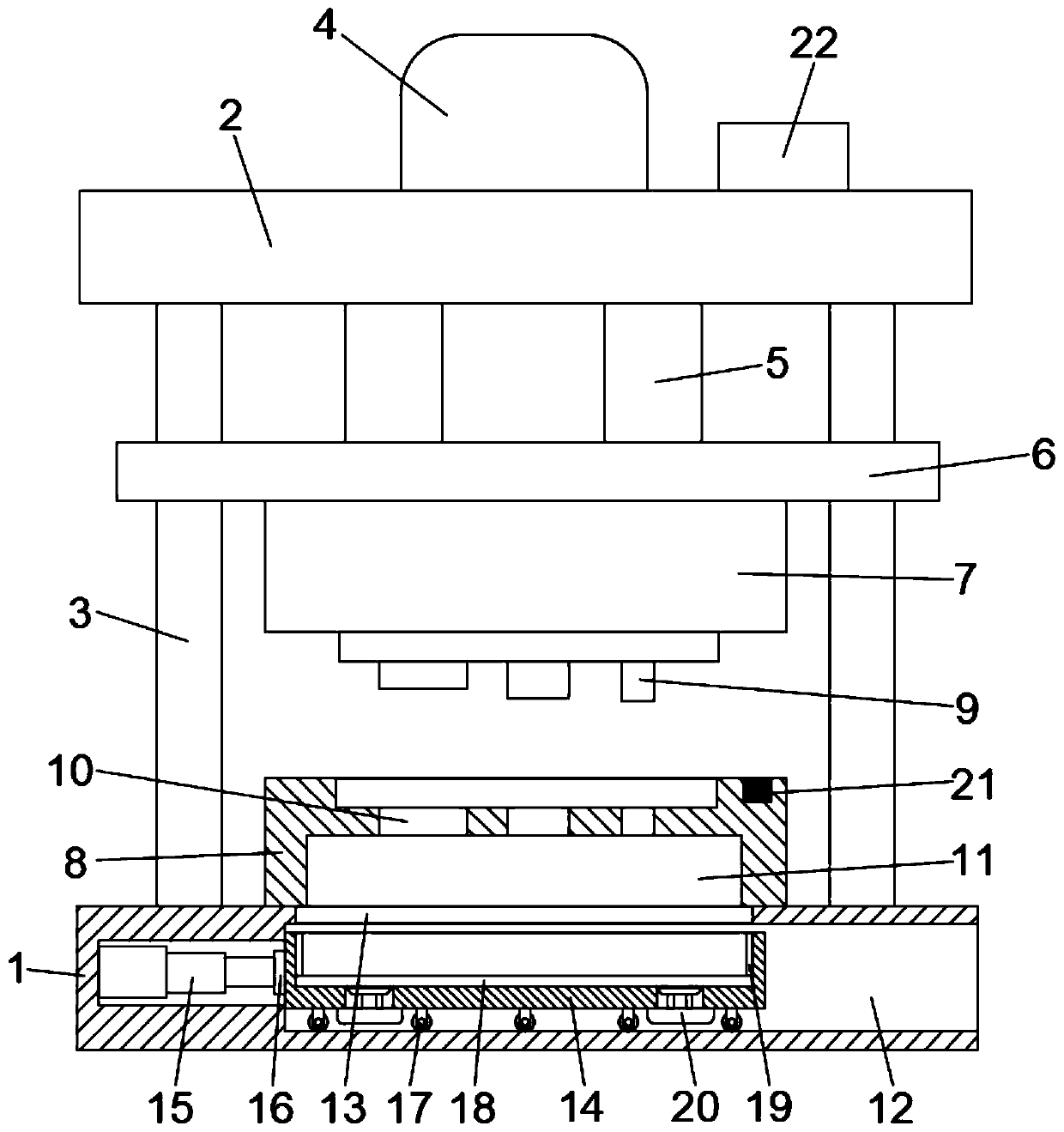

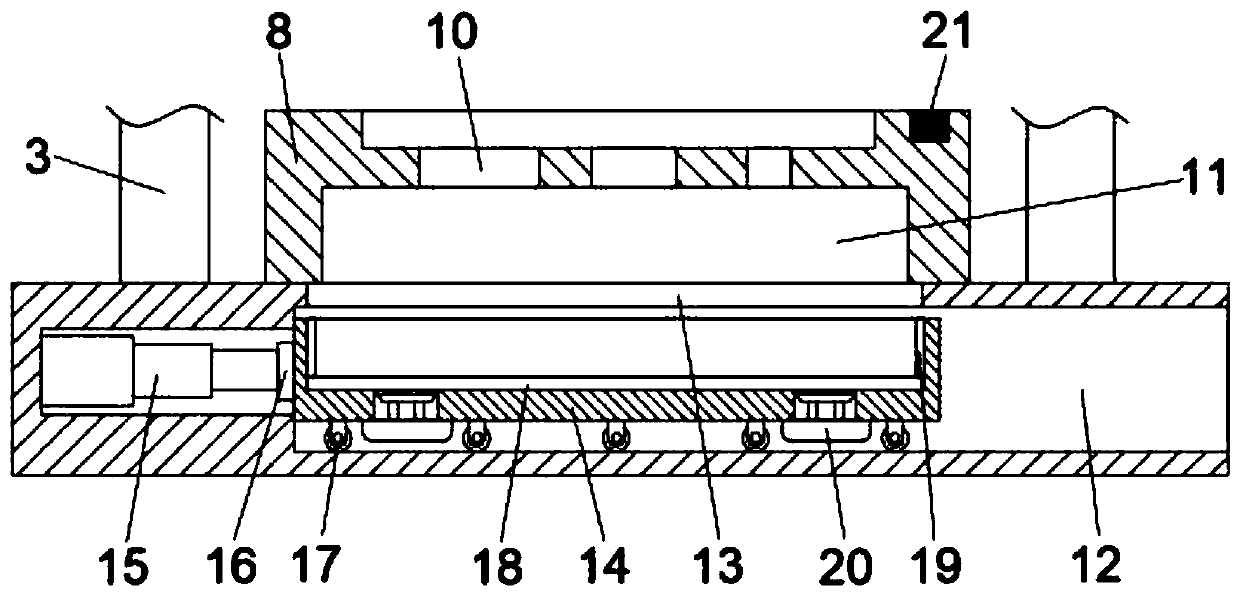

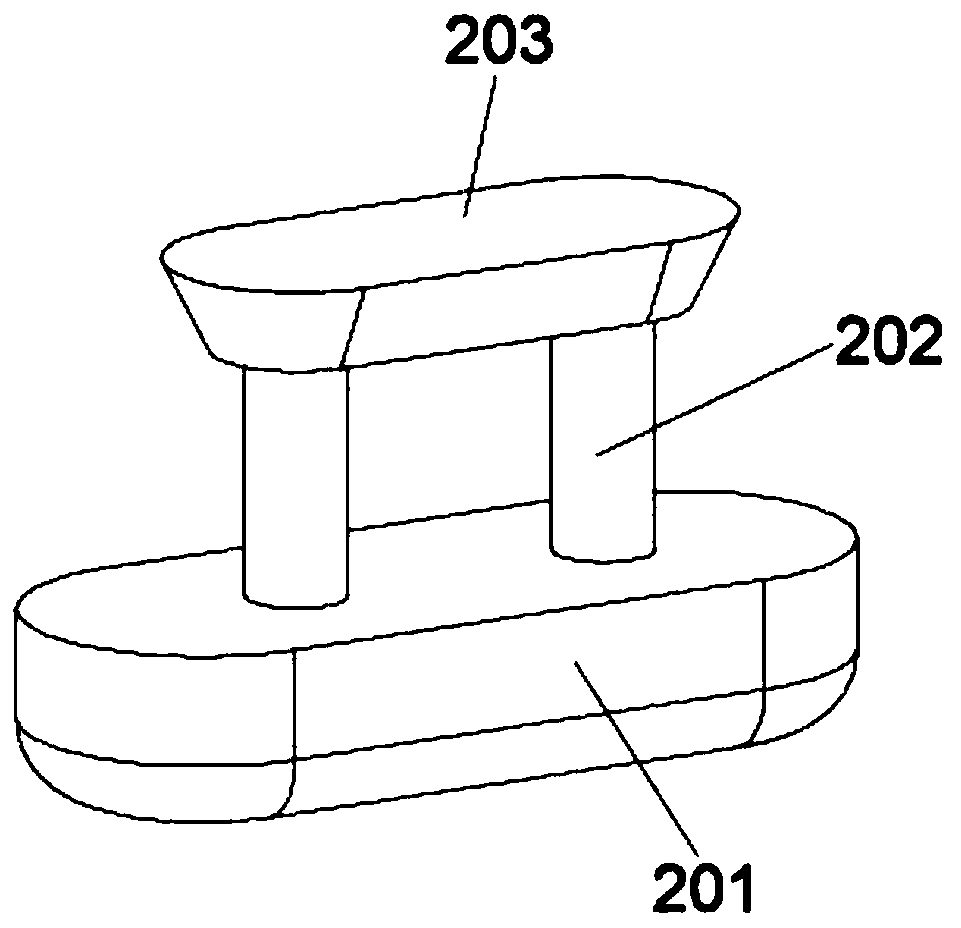

[0024] see Figure 1-2 , a stamping die to facilitate the discharge of waste materials, including a base 1 and a top plate 2, a support column 3 is vertically fixed between the base 1 and the top plate 2, a hydraulic press 4 is installed on the top plate 2, and the lower end of the hydraulic press 4 is connected to There is a telescopic cylinder 5 vertically penetrating the top plate 2. The bottom of the telescopic cylinder 5 is fixed with a lifting plate 6 slidingly sleeved on the support column 3. An upper mold 7 is installed on the lower end of the lifting plate 6. On the base 1 The end face is equipped with a lower mold 8, the upper mold 7 is provided with a stamping block 9, the lower mold 8 is provided with a punching hole 10 corresponding to the stamping block 9, and the bottom of the lower mold 8 is provided with a punching hole 10 connected to the empty slot 11; the base 1 is provided with a chamber 12, the top of the chamber 12 is provided with an opening 13 communic...

Embodiment 2

[0034] A stamping die for facilitating waste discharge, comprising a base 1 and a top plate 2, a support column 3 is vertically fixed between the base 1 and the top plate 2, a hydraulic press 4 is installed on the top plate 2, and the lower end of the hydraulic press 4 is connected with The telescopic cylinder 5 vertically runs through the top plate 2, the bottom of the telescopic cylinder 5 is fixed with a lifting plate 6 slidingly sleeved on the support column 3, the lower end of the lifting plate 6 is equipped with an upper mold 7, and the upper end of the base 1 is A lower mold 8 is installed, the upper mold 7 is provided with a stamping block 9, the lower mold 8 is provided with a punching hole 10 corresponding to the stamping block 9 one by one, and the bottom of the lower mold 8 is provided with a punching hole 10 A connected hollow groove 11; a chamber 12 is provided in the base 1, an opening 13 communicating with the hollow groove 11 is arranged above the chamber 12, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com