Preparation containing stalactite bio-calcium, for balancing bodies, and production method of preparation containing stalactite bio-calcium, for balancing bodies

A production method, stalactite technology, applied in the field of preparations containing stalactite bio-calcium in the body, can solve problems such as unsatisfactory effects, and achieve effects that are beneficial to gastrointestinal health, good effect, and blood purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

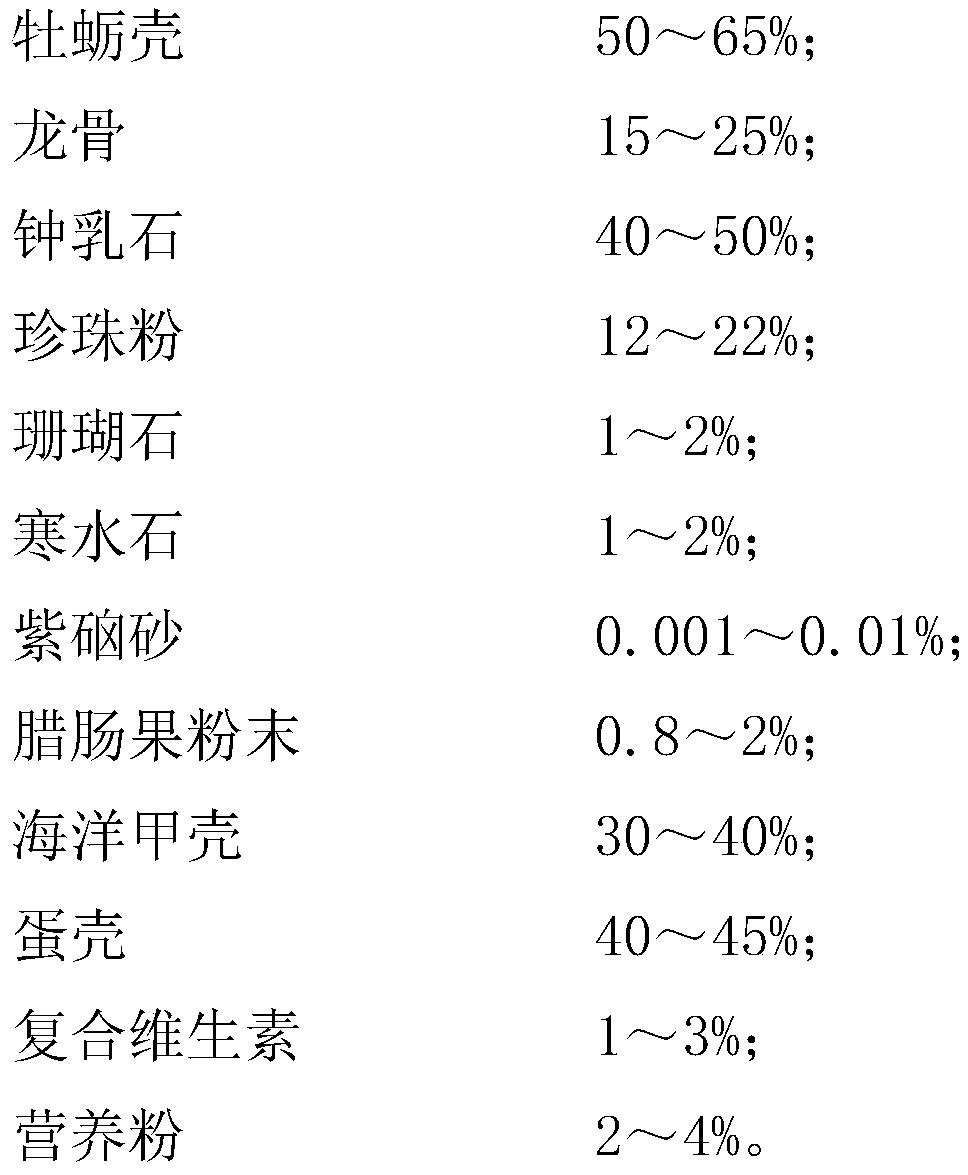

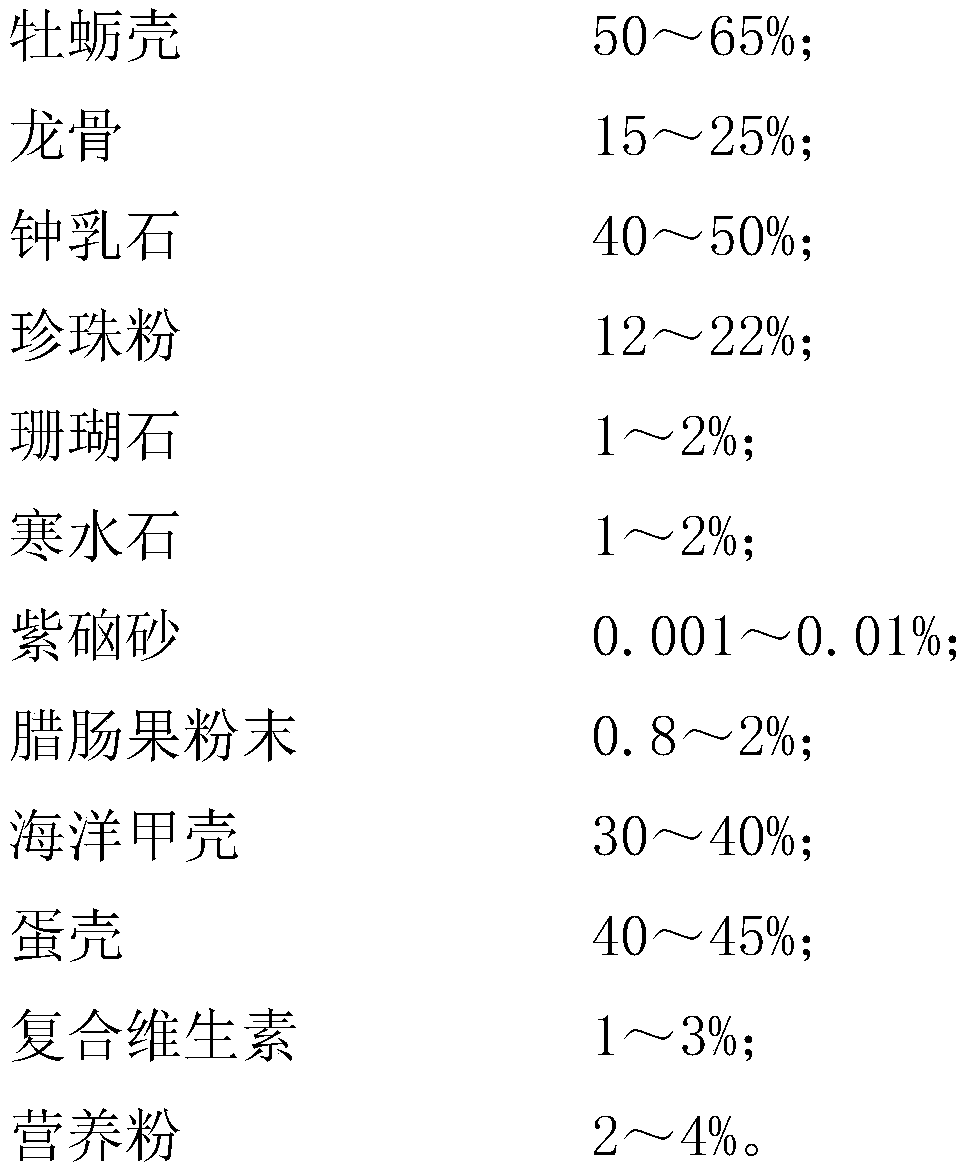

[0062] 1) Cleaning, cleaning and screening oyster shells, keels, marine carapaces, eggshells, and coral stones, then preliminarily crushing them, putting them into disinfection and sterilization solutions, then rinsing, and drying;

[0063] 2) Grinding, the stalactite, pearl powder, cold water stone, purple nao sand are carried out preliminary grinding respectively;

[0064] 3) high-temperature vacuum electrolysis, take step 1) in 50% by weight of oyster shells, 15% by weight of keels; 30% by weight of marine carapaces; 40% by weight of eggshells; 40% by weight of stalactites; Coral stone; 1% by weight of Hanshui stone; 0.001% by weight of purple sand, electrolyzed in vacuum at 1600°C;

[0065] 4) Activation, mixing the product after electrolysis with 12% by weight of pearl powder and 0.8% by weight of sausage fruit powder, adding ethanol to the mixed material according to the ratio of 1:4.5 and heating to reflux for 1.5 hours;

[0066] 5) Reverse osmosis, vacuum concentratio...

Embodiment 2

[0075] 1) Cleaning, cleaning and screening oyster shells, keels, marine carapaces, eggshells, and coral stones, then preliminarily crushing them, putting them into disinfection and sterilization solutions, then rinsing, and drying;

[0076] 2) Grinding, the stalactite, pearl powder, cold water stone, purple nao sand are carried out preliminary grinding respectively;

[0077] 3) High-temperature vacuum electrolysis, take step 1) in 65% by weight of oyster shells, 25% by weight of keels; 40% by weight of marine carapaces; 45% by weight of eggshells; Coral stone: 2% by weight of Hanshui stone, 0.01% by weight of purple nao sand, under the condition of 2000 ℃, vacuum electrolysis;

[0078] 4) Activation, mixing the product after electrolysis with 22% by weight of pearl powder and 2% by weight of sausage fruit powder, adding ethanol to the mixed material according to the ratio of 1:4.5 and heating to reflux for 2.5 hours;

[0079] 5) Reverse osmosis, vacuum concentration and dryin...

Embodiment 3

[0088] 1) Cleaning, cleaning and screening oyster shells, keels, marine carapaces, eggshells, and coral stones, then preliminarily crushing them, putting them into disinfection and sterilization solutions, then rinsing, and drying;

[0089] 2) Grinding, the stalactite, pearl powder, cold water stone, purple nao sand are carried out preliminary grinding respectively;

[0090] 3) High-temperature vacuum electrolysis, take step 1) in 55% by weight of oyster shells, 20% by weight of keels; 35% by weight of marine carapaces; 42% by weight of eggshells; Coral stone; 1% by weight of hanshui stone; 0.006% by weight of azurite sand, under the condition of 18010 ℃, vacuum electrolysis;

[0091] 4) Activation, mixing the electrolyzed product with 18% by weight of pearl powder and 0.9% by weight of sausage fruit powder, adding ethanol to the mixed material according to the ratio of 1:4.5 and heating to reflux for 2 hours;

[0092] 5) Reverse osmosis, vacuum concentration and drying, osmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com