Manufacturing installation for producing winding bar for electric motor, and method for producing winding bar

A technology for manufacturing equipment and winding wires, applied in the field of manufacturing equipment, can solve problems such as time-consuming and high investment costs, and achieve the effect of short cycle time and high processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] First of all, it should be confirmed that, in the different described embodiments, the same components have the same reference numerals or the same component names, and the disclosure contained in the entire specification can be reasonably transferred to the same reference numerals or the same component names. same parts. The position descriptions used in the description, such as eg top, bottom, side, etc., refer to the current description and the figures shown and can be appropriately transferred to the new position in the event of a change of position.

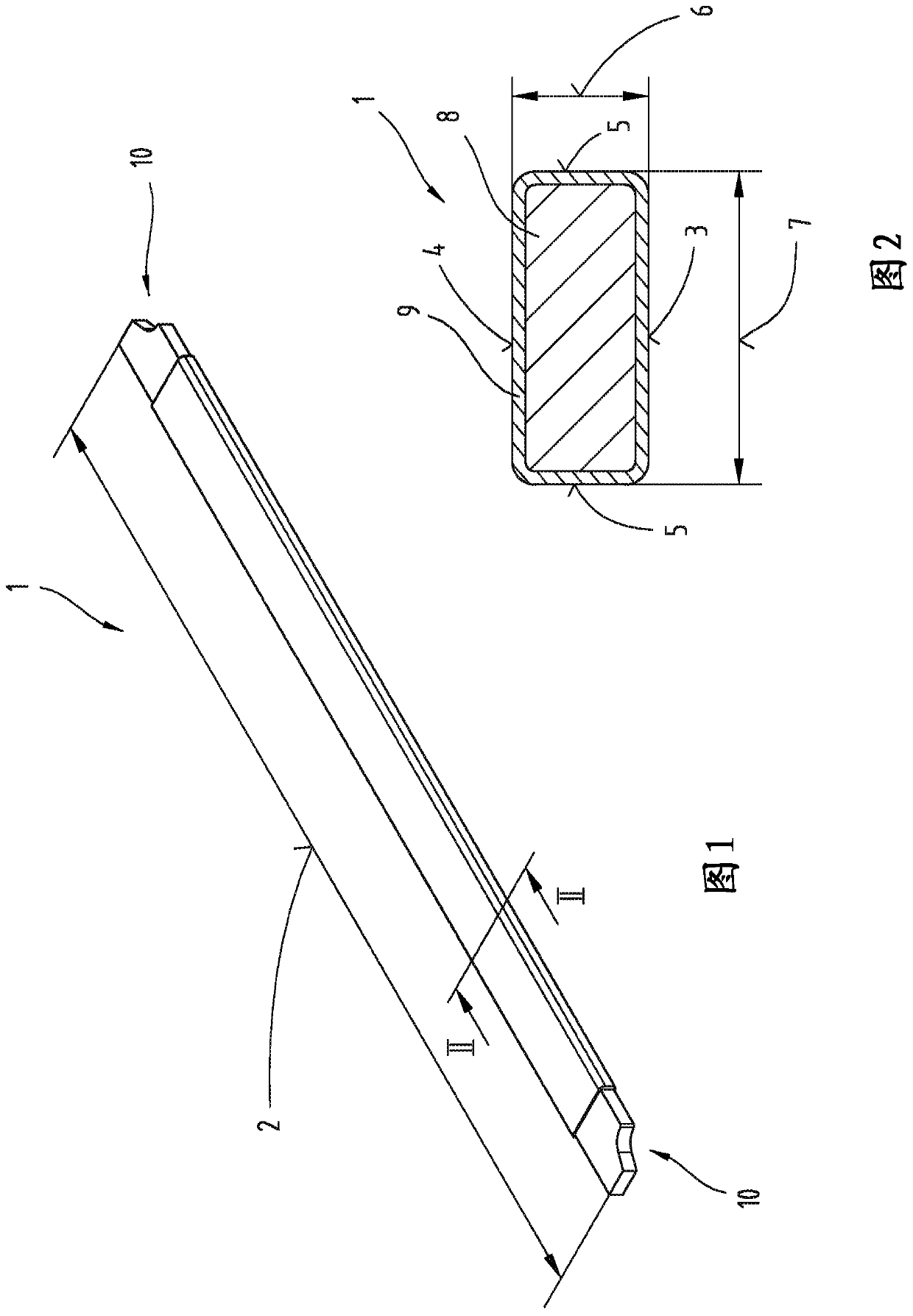

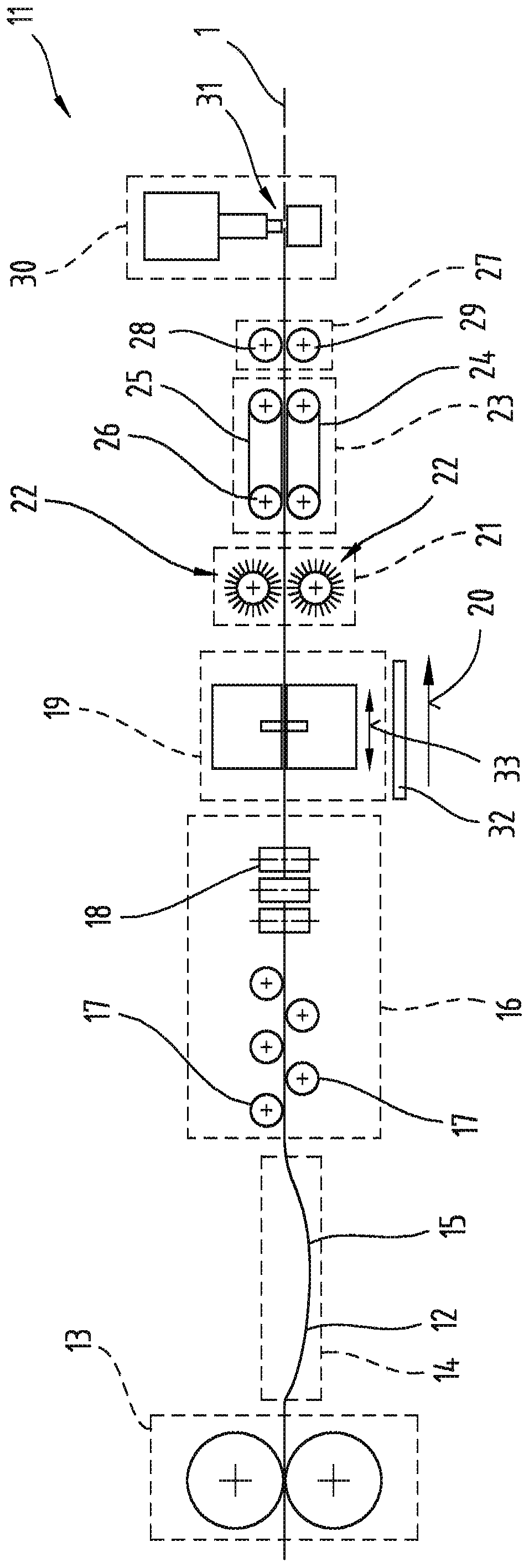

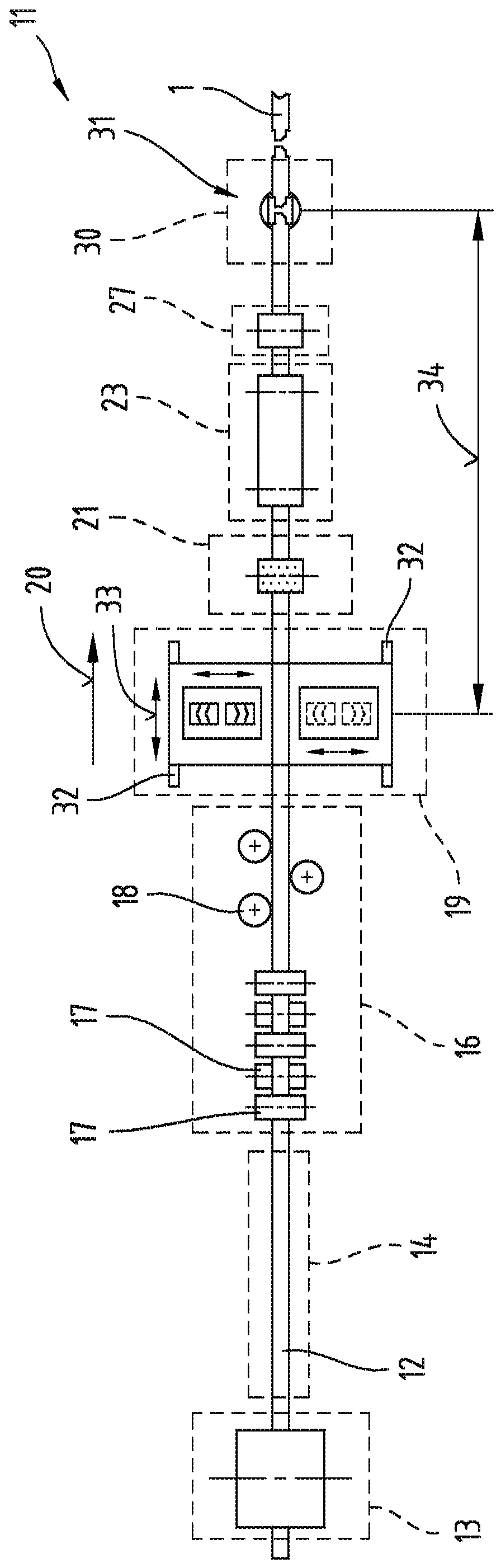

[0070] figure 1 A perspective view is shown of a winding bar 1 used to manufacture windings in electric machines. The use of winding bars 1 in electric machines is described in DE 10 2015 217 922 A1. The winding bar 1 has a bar length 2, which can be selected differently according to the specifications of the motor. In particular, it is also conceivable that the winding bars 1 for the same electrical machine can ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com