Cylinder and the machine including the cylinder

A technology of cylinders and machines, applied in the direction of fluid pressure actuation devices, etc., can solve problems such as dropping, lowering processing quality, and not closing the door tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

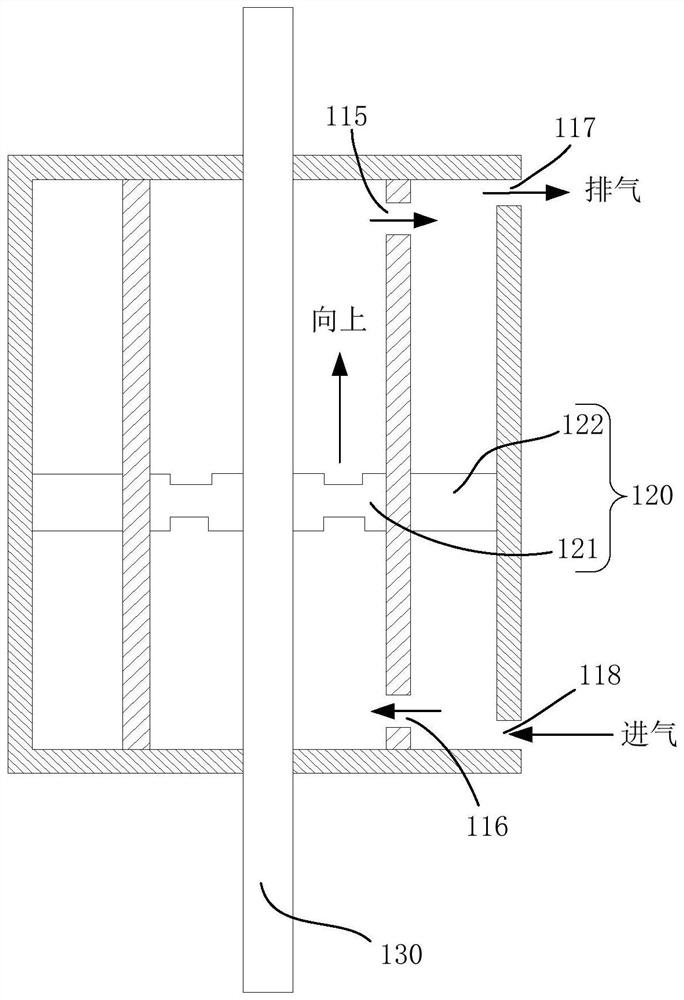

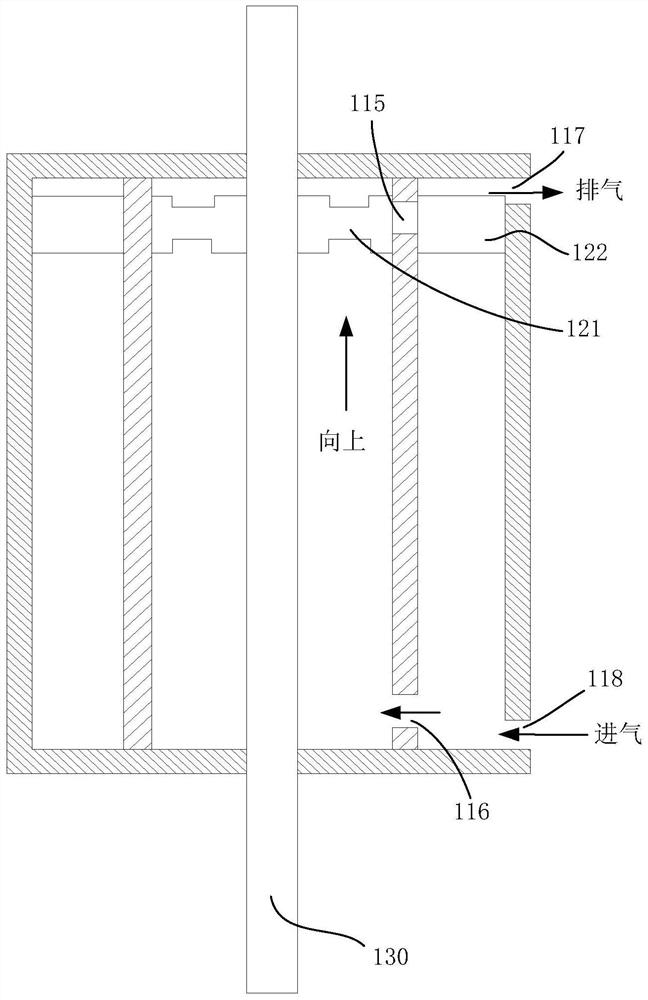

[0048] As mentioned in the background technology, the inventors found that the door between the transfer chamber and the etching chamber of the dry etching machine is often not closed tightly, and the wafer is also prone to shaking, falling, etc., and the surface of the wafer is also prone to deposit side effects product. The inventor further researched and found that because the cylinder is a single cylinder and is easily damaged, the door is often not closed tightly, causing the machine to stop frequently or stop production, reducing production efficiency. In addition, based on the reason that the cylinder is easy to vibrate during the working process, the wafer bounces and even falls. Sometimes the vibration of the cylinder can easily cause the by-products on the etching cavity wall to loosen and fall on the surface of the wafer during the etching process, causing Wafer surface defects.

[0049] In order to solve the problem that the single cylinder is easily damaged, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com