Movable bottom seat of energy-saving vortex air compressor and mounting method thereof

A mobile base and air compressor technology, applied in the direction of mobile frames, engine frames, machines/engines, etc., can solve problems such as inconvenient installation, unable to install air compressors, and unable to reduce damage to scroll air compressors, etc. To achieve the effect of easy installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

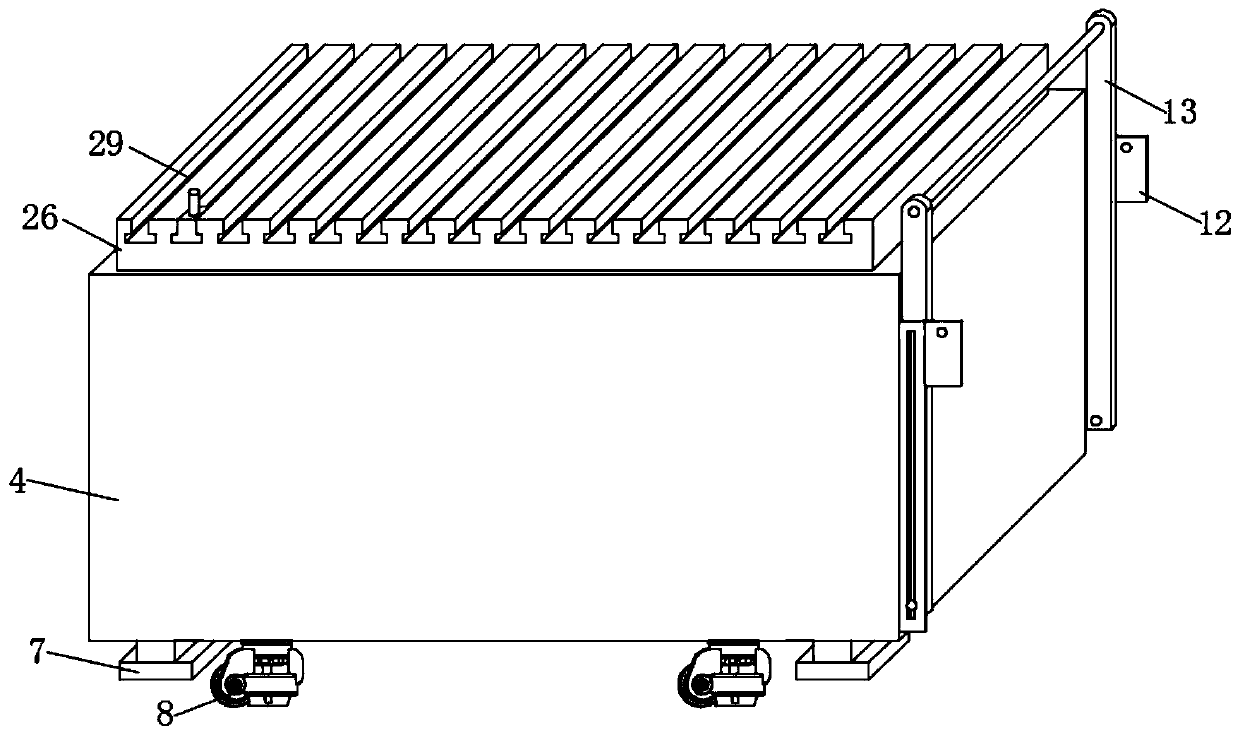

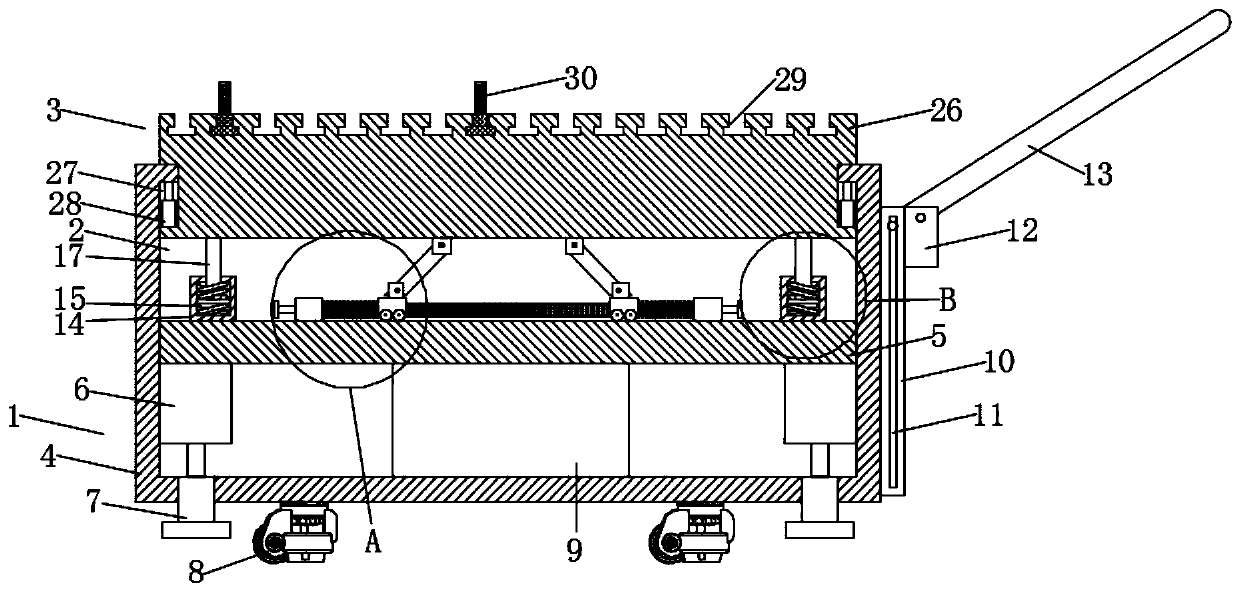

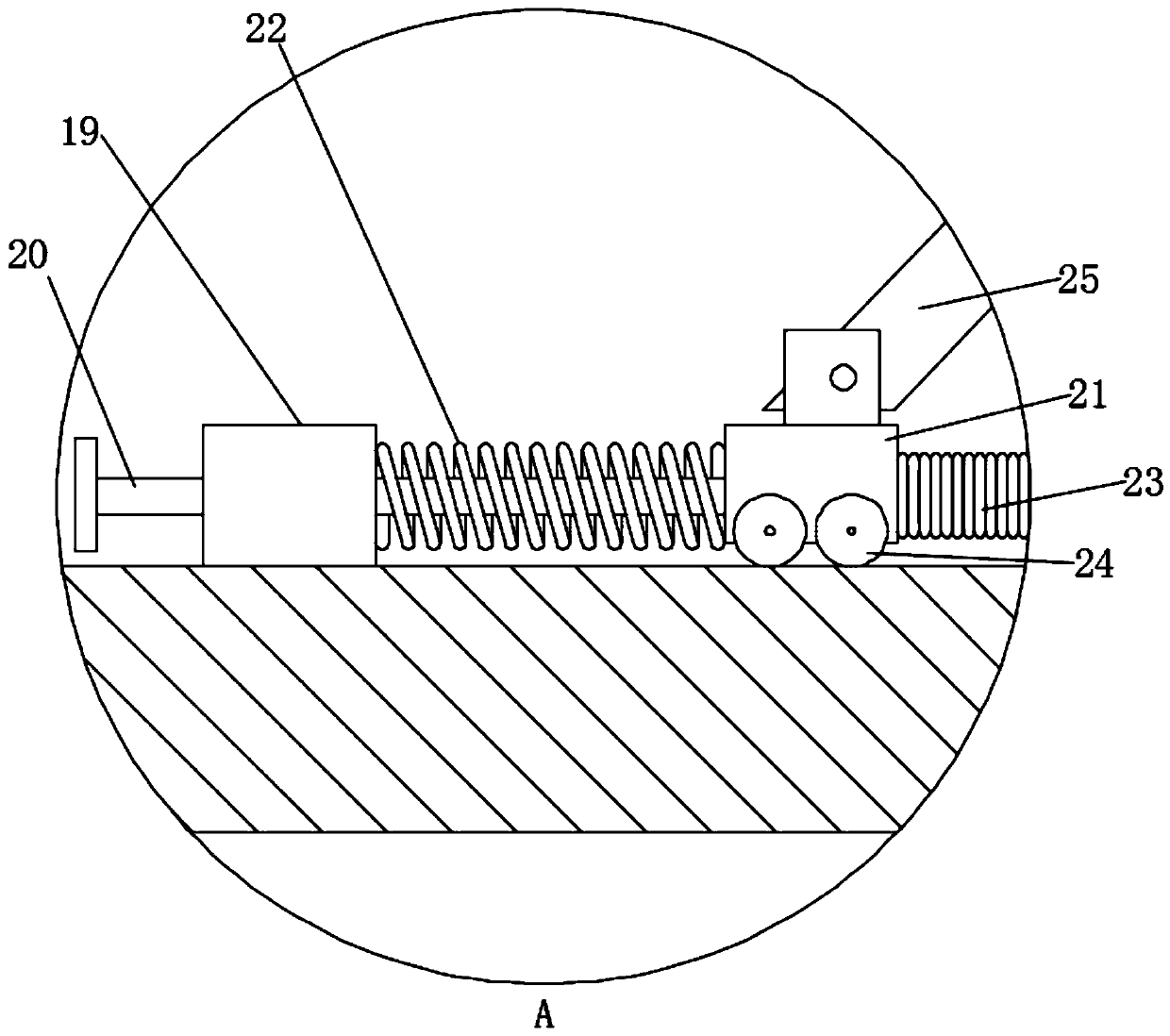

[0025] A mobile base of an energy-saving scroll air compressor, comprising a supporting mechanism 1, a shock absorbing mechanism 2 and a mounting mechanism 3, the top of the supporting mechanism 1 is equipped with a shock absorbing mechanism 2, and the top of the shock absorbing mechanism 2 is installed with The installation mechanism 3, the support mechanism 1 includes a support box 4, a fixed partition 5, a support hydraulic cylinder 6, a support foot plate 7, a self-locking wheel 8, a hydraulic station 9, an adjustment plate 10, an adjustment chute 11, and a limit plate 12 and handrails 13, the inside of the support box 4 is fixedly equipped with a fixed partition 5, and the four corners of the bottom of the fixed partition 5 are fixedly installed with a support hydraulic cylinder 6, and the output end of the support hydraulic cylinder 6 is connected from The bottom of the supporting box body 4 passes through, and the output ends of the supporting hydraulic cylinders 6 are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com