Screw rotor group and hydrogen circulation pump with the screw rotor group

A technology of rotor group and screw, which is applied in the direction of rotary piston/oscillating piston pump components, rotary piston pumps, components of pumping devices for elastic fluid, etc., and can solve the air tightness of twin-screw hydrogen circulation pumps And problems such as poor volumetric efficiency, low area utilization coefficient, complex structure, etc., to achieve the effect of improving area utilization coefficient, good air tightness and volumetric efficiency, and increasing volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] For a better understanding of the application, various aspects of the application will be described in more detail with reference to the accompanying drawings. It should be understood that these detailed descriptions are descriptions of exemplary embodiments of the application only, and are not intended to limit the scope of the application in any way.

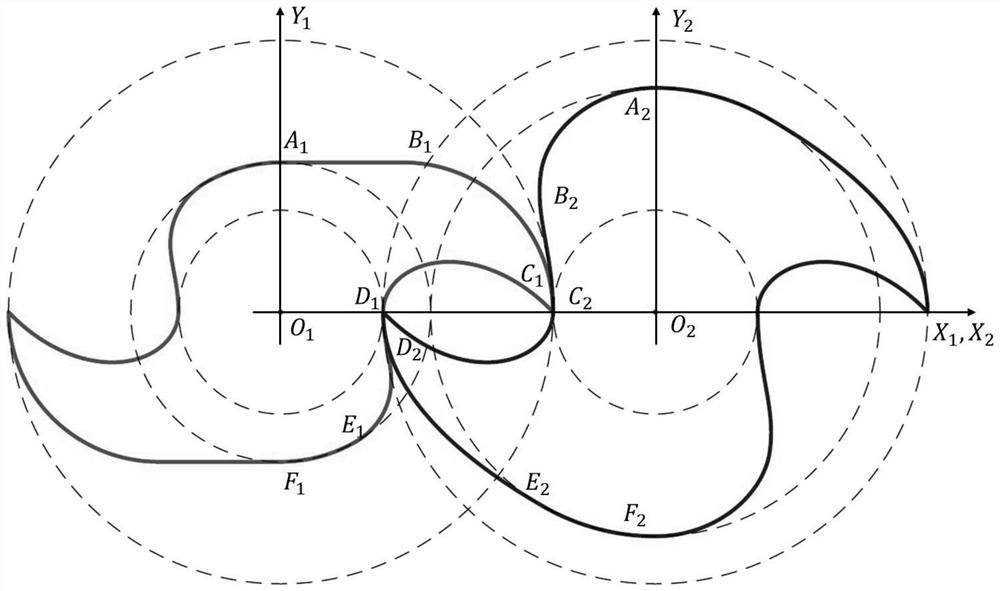

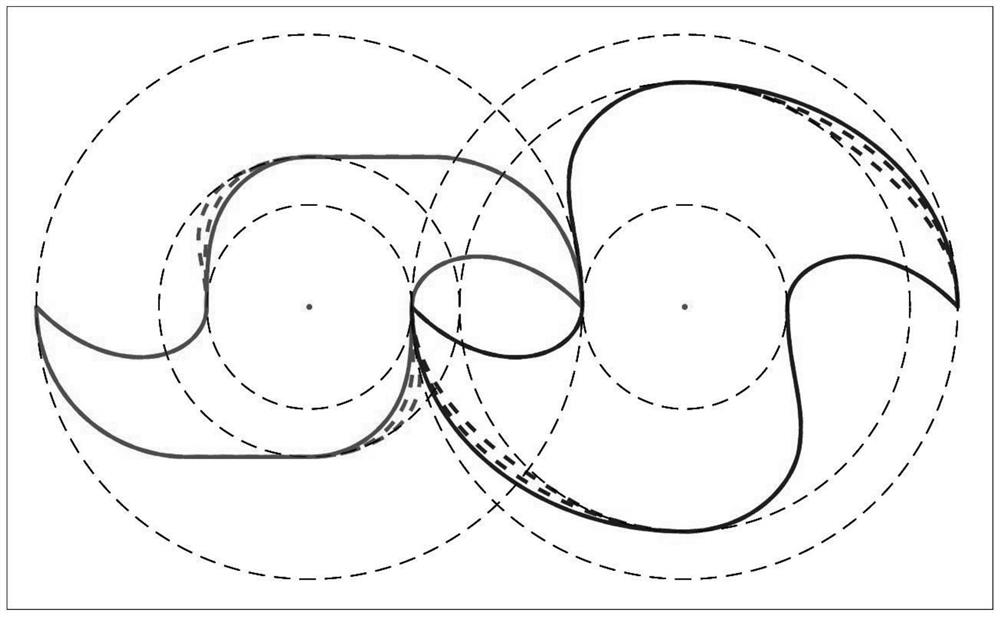

[0048] The invention discloses a screw rotor assembly, which includes a driving rotor and a driven rotor, the driving rotor and the driven rotor are meshed with each other; the driven rotor profile includes a straight line A 1 B 1 , the first transition arc B 1 C 1 , point meshing cycloid C 1 D. 1 , transition curve conjugate line D 1 E. 1 and the second transition arc E 1 f 1 ; The profile of the active rotor includes a linear conjugate envelope A 2 B 2 , the first transition arc conjugate envelope B 2 C 2 , point meshing cycloid C 2 D. 2 , transition curve D 2 E. 2 and the second transition arc conjuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com