Modular assembling method of steel box girder bridge

A steel box girder, modular technology, applied in the direction of bridges, bridge construction, bridge materials, etc., can solve the problems of affecting the safety of bridge structures, delaying construction progress, increasing construction costs, etc., to improve construction efficiency and quality, and accurate spatial location , The effect of reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but it is not intended as a limitation of the present invention.

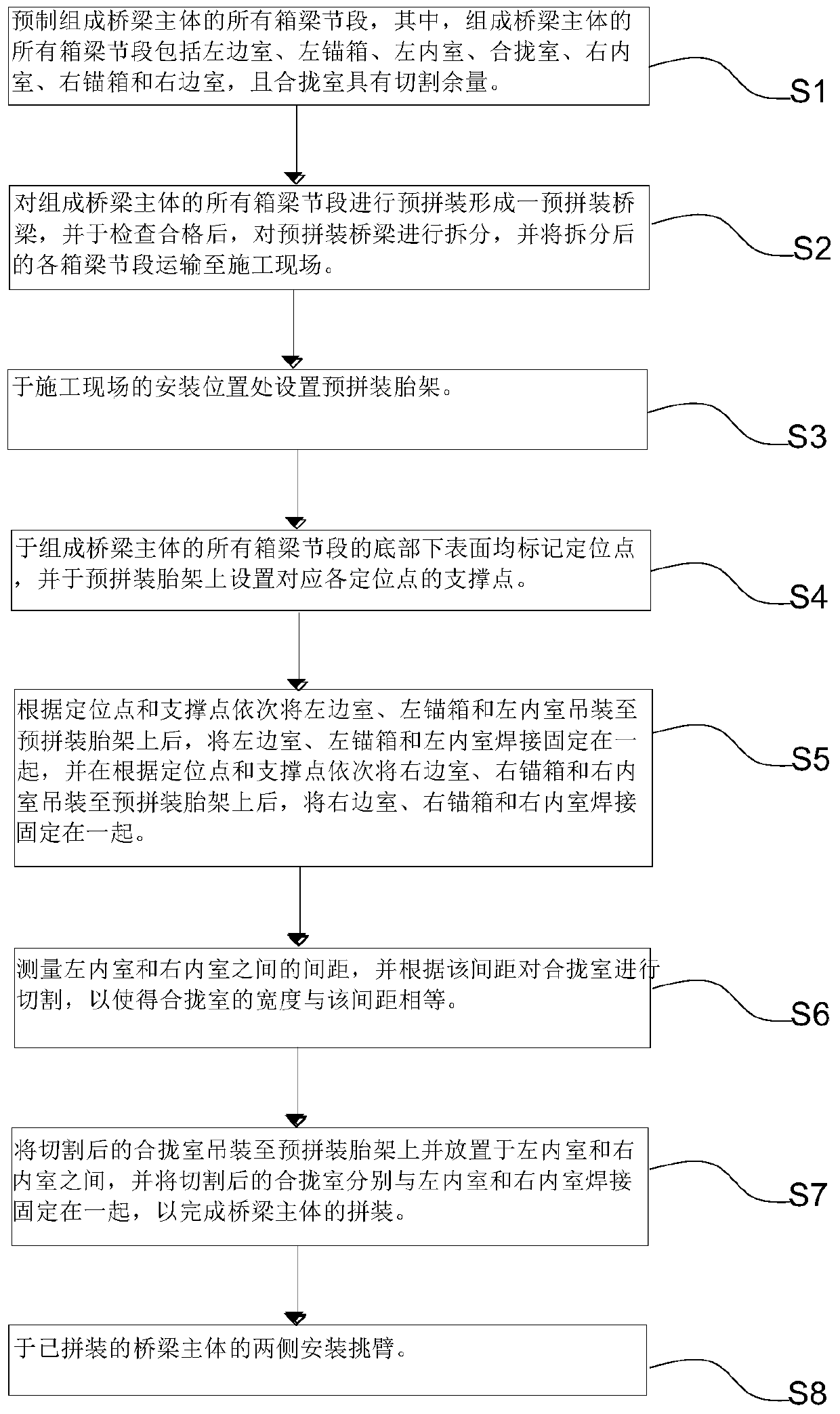

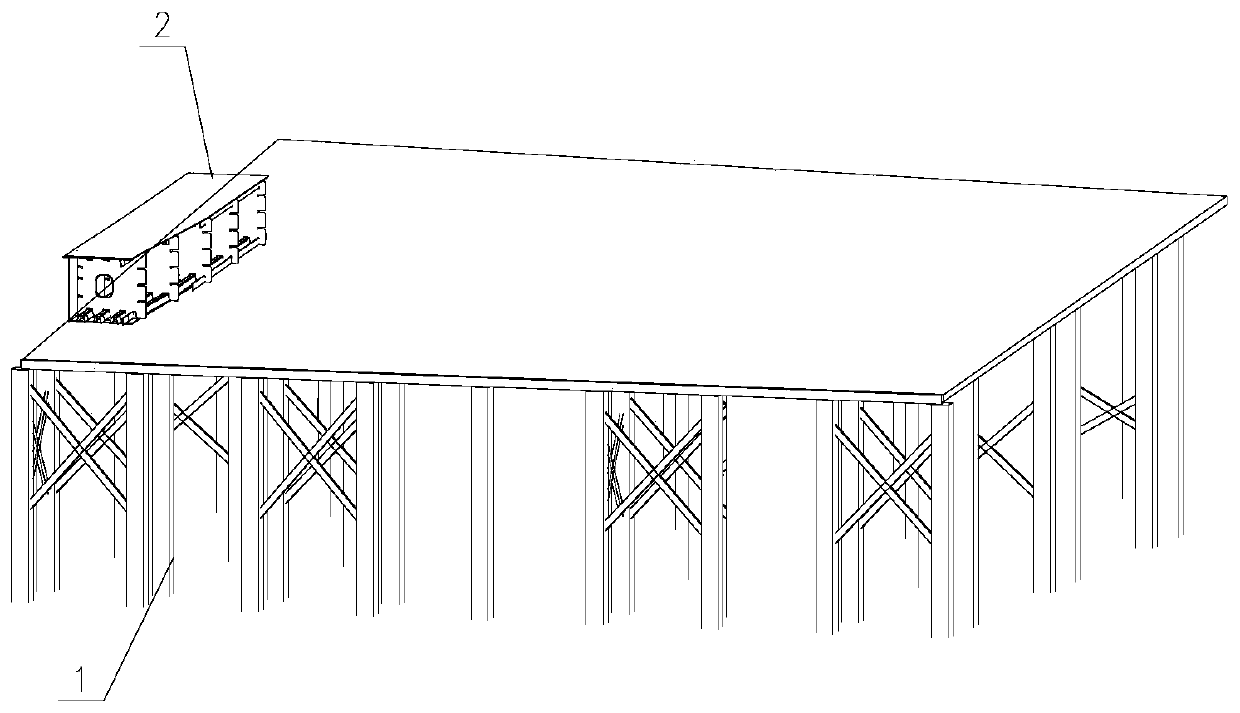

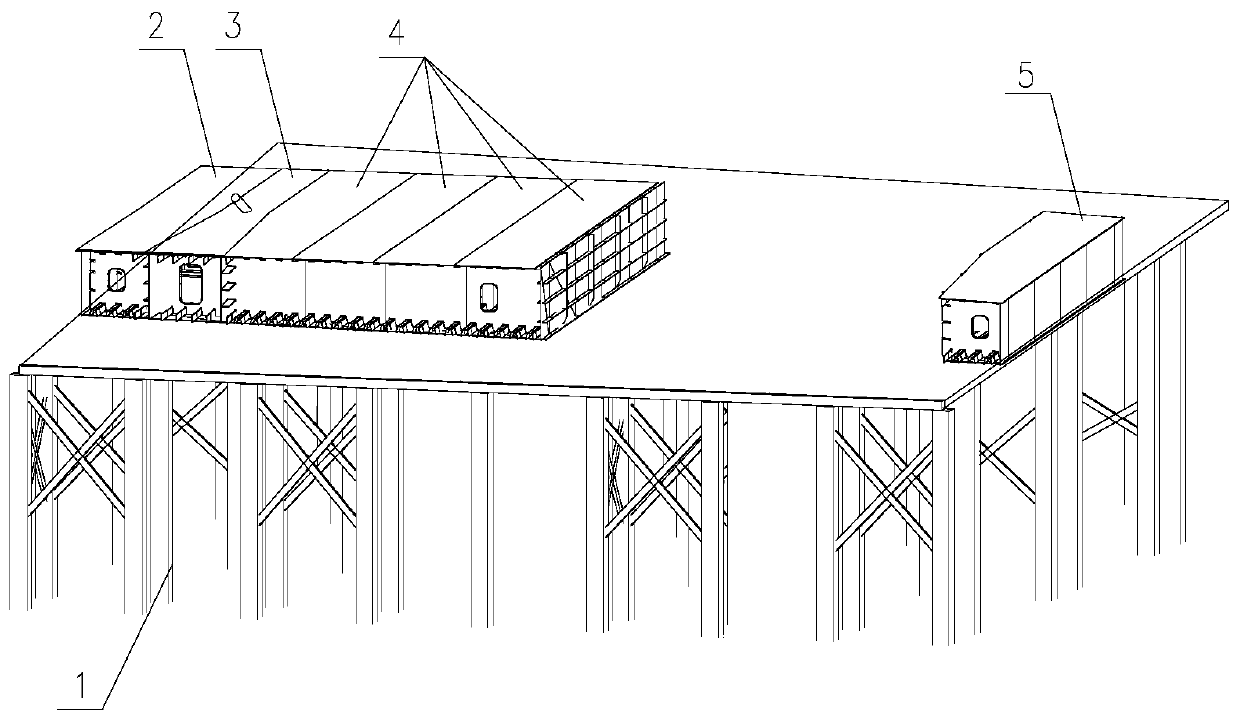

[0037] Such as Figure 1~5 As shown, the present invention discloses a modular assembly method of a steel box girder bridge. The steel box girder bridge includes a bridge body in the middle and pick arms (respectively left pick arm 10 and right pick arm 9) positioned at both sides of the bridge body. ), specifically, the method includes the following steps:

[0038] Step S1, prefabricating all the box girder segments that make up the main body of the bridge, specifically, all the box girder segments that make up the main body of the bridge include the left chamber 2, the left anchor box 3, the left inner chamber 4, and the closing chamber 8 (that is, the inner chamber), right inner chamber 7, right anchor box 6 and right chamber 5, and the closing chamber 8 has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com