Method for treating rare earth ore mining wastewater by adding inorganic carbon source reinforced microalgae

A technology of mining wastewater and inorganic carbon source, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficult domestication, high operating costs, and unfavorable physiological activity of nitrifying and denitrifying bacteria. impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention does not specifically limit the source of the mixed microalgae. Specifically, in the present invention, the preparation method of the mixed microalgae preferably includes the following steps:

[0033] Mix rare earth mining wastewater with phosphorus-containing compounds to obtain microalgae domestication wastewater;

[0034] The domesticated microalgae is obtained by mixing the microalgae domestication waste water with the algae source water; the algae source water contains Chlorella and Chlorella;

[0035] The domesticated microalgae are enriched and amplified to obtain mixed microalgae.

[0036] The invention mixes rare earth ore mining wastewater and phosphorus-containing compounds to obtain microalgae domestication wastewater. In the present invention, the nitrogen-to-phosphorus ratio of the microalgae domestication wastewater is preferably 5 to 6:0.5 to 1.5, more preferably 5:1; The optional range is preferably consistent with the above tech...

Embodiment 1

[0052] The preparation method of the mixed microalgae of chlorella and chlorococcus comprises the following steps:

[0053] (1) Add 1L of rare earth ore mining wastewater into the beaker, adjust the nitrogen-phosphorus ratio of the rare earth ore mining wastewater to 5:1 with dipotassium hydrogen phosphate, then add 0.5mL of river water, at a temperature of 28°C and a humidity of 60% 30 days of domestication under natural light conditions (specifically carried out in an open environment exposed to the air), to obtain domesticated microalgae;

[0054] (2) Prepare 1L liquid medium for use, the specific formula is Na 2 CO 3 1500mg / L, K 2 HPO 4 40mg / L, MgSO 4 50mg / L, CaCl 2 20mg / L, ferric citrate 6mg / L, agar 20g / L and the rest of water;

[0055] (3) Take 0.5 mL of the domesticated microalgae at the bottom of the beaker in step (1), inoculate it in the liquid medium of step (2), and then put it into a constant temperature room. Under the condition of 10000Lx (using the LED l...

Embodiment 2

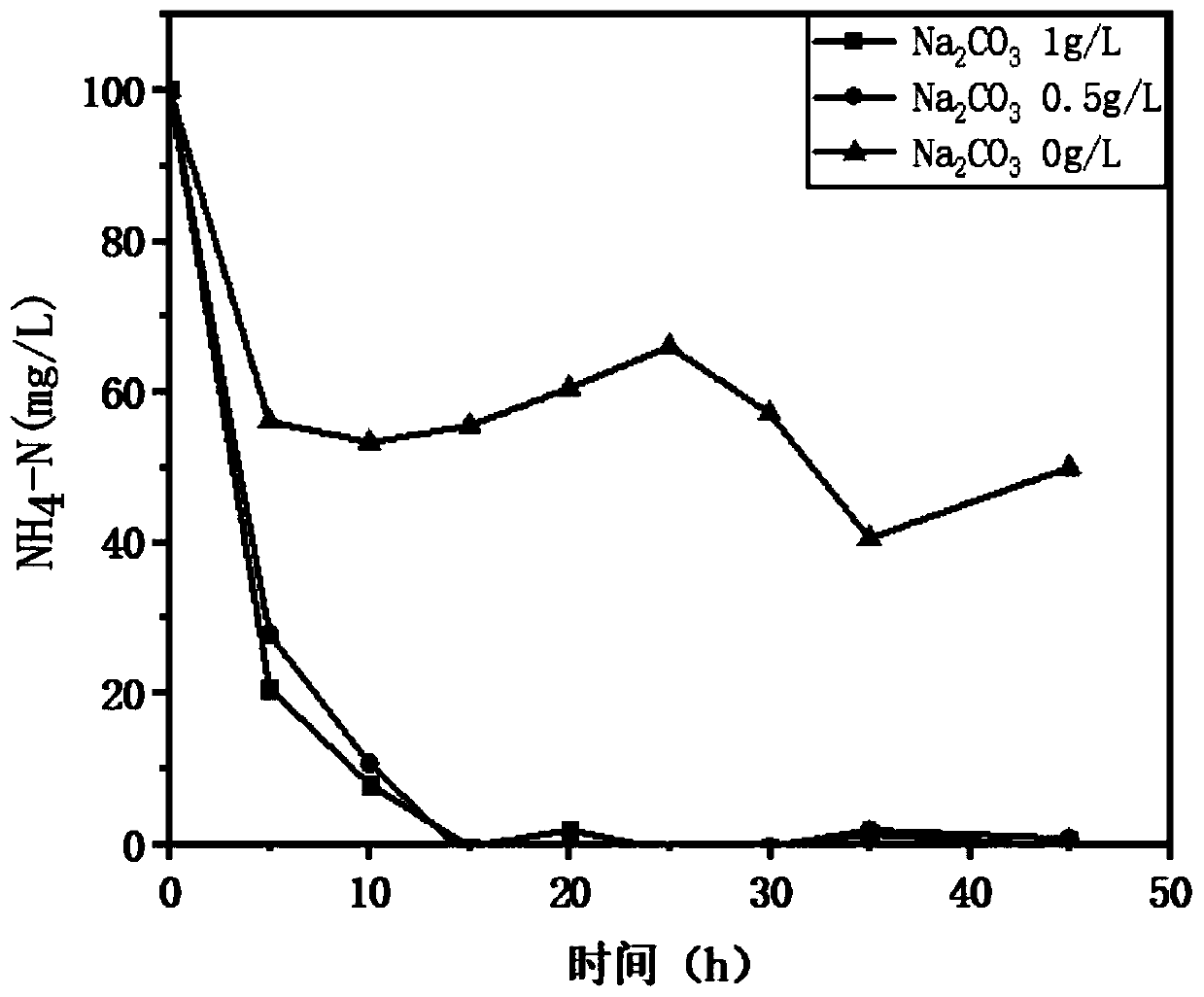

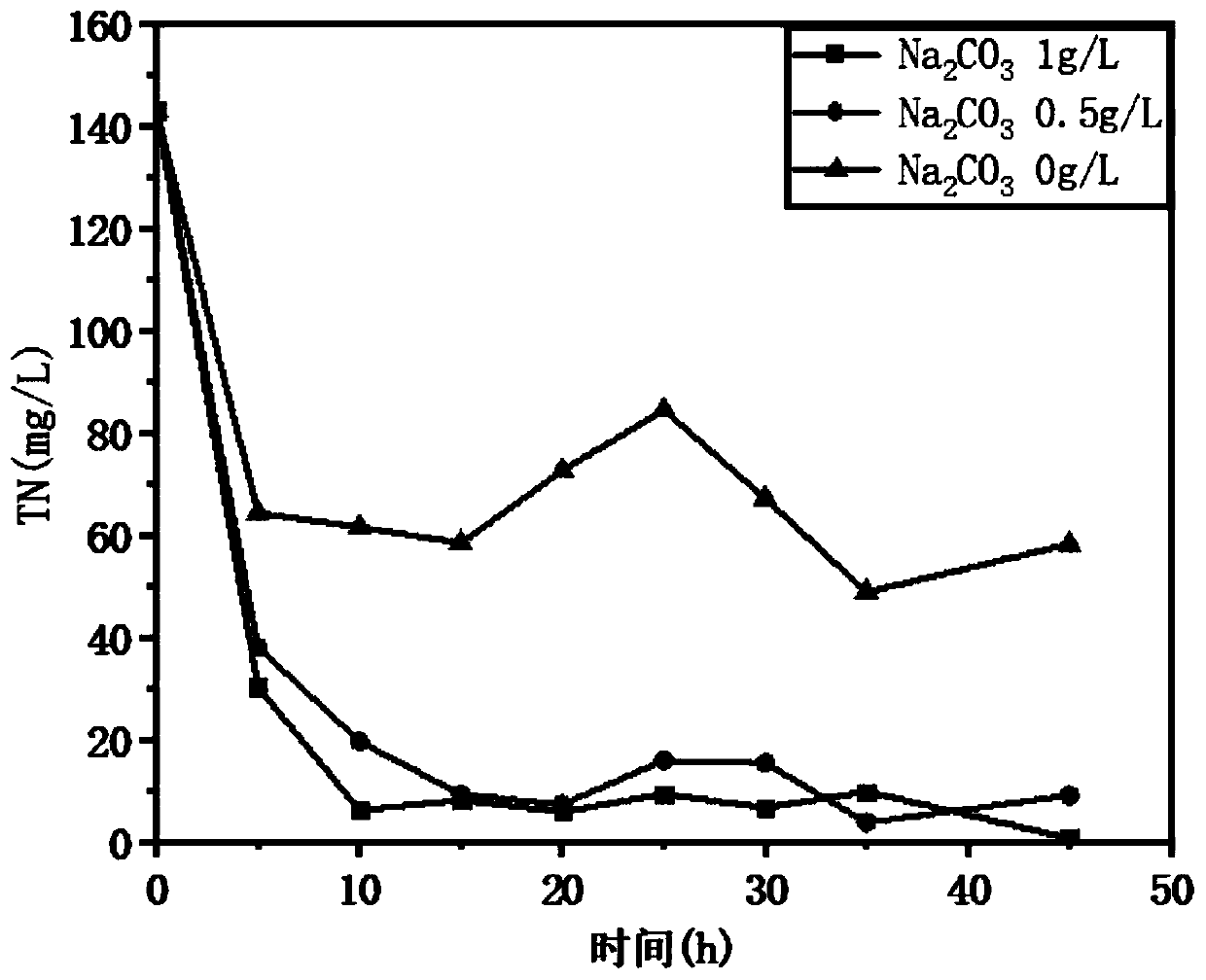

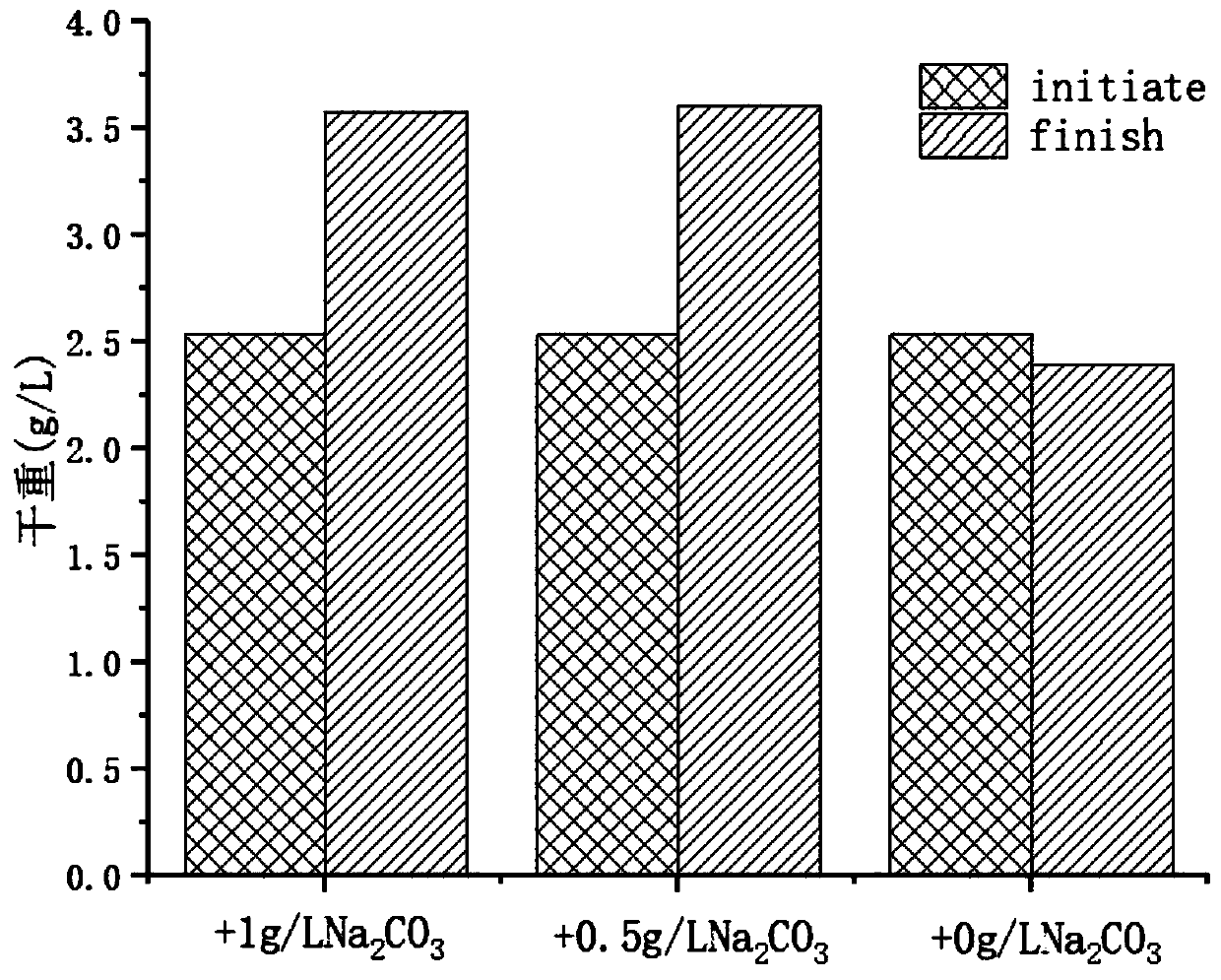

[0057] (1) Dipotassium hydrogen phosphate is used to adjust the nitrogen-phosphorus ratio of rare earth mining wastewater to be 5:1, and then it is divided into three parts, and 0g / L sodium carbonate, 0.5g / L sodium carbonate, and 1g / L sodium carbonate are added respectively to obtain Three parts of waste water to be purified;

[0058] (2) Get the mixed microalgae of Chlorella prepared in Example 1 and Chlorococcus, add respectively in three parts of waste water to be purified in step (1), each part of waste water to be purified is 1L, wherein, with According to the dry weight of the mixed microalgae, the dosage of the mixed microalgae in each part of waste water to be purified is 2.5g, and then the temperature is 26°C, the humidity is 55%, and the light intensity is 8000Lx (using LED lamp tubes to provide light) Purification treatment was carried out for 15 hours under certain conditions; after the purification treatment was completed, the obtained system was naturally settled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com