Tension control device suitable for light fabric

A tension control and fabric technology, used in transportation and packaging, strip winding, thin material handling, etc., to solve problems such as large tension changes and large sliding friction between rollers and warp yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

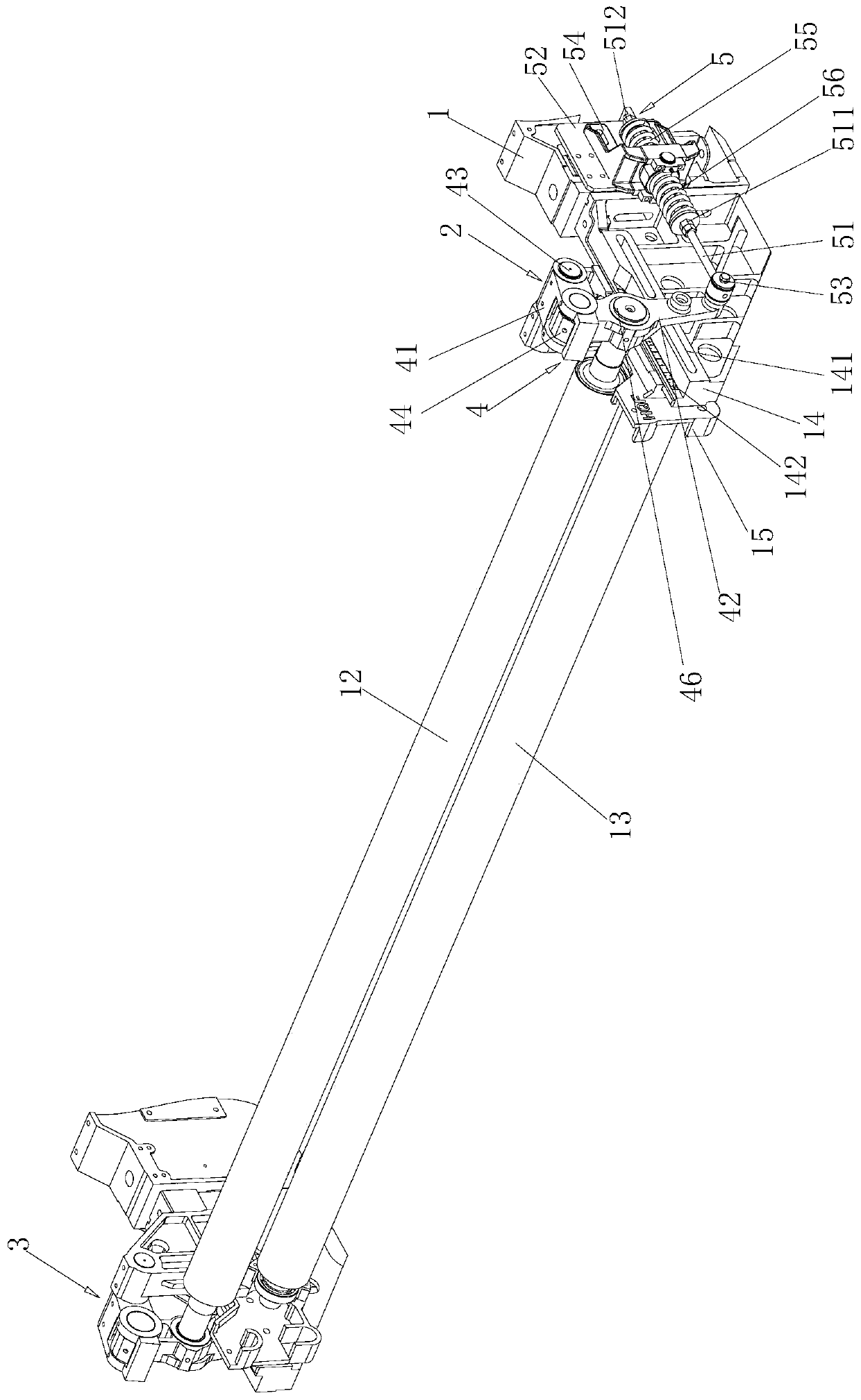

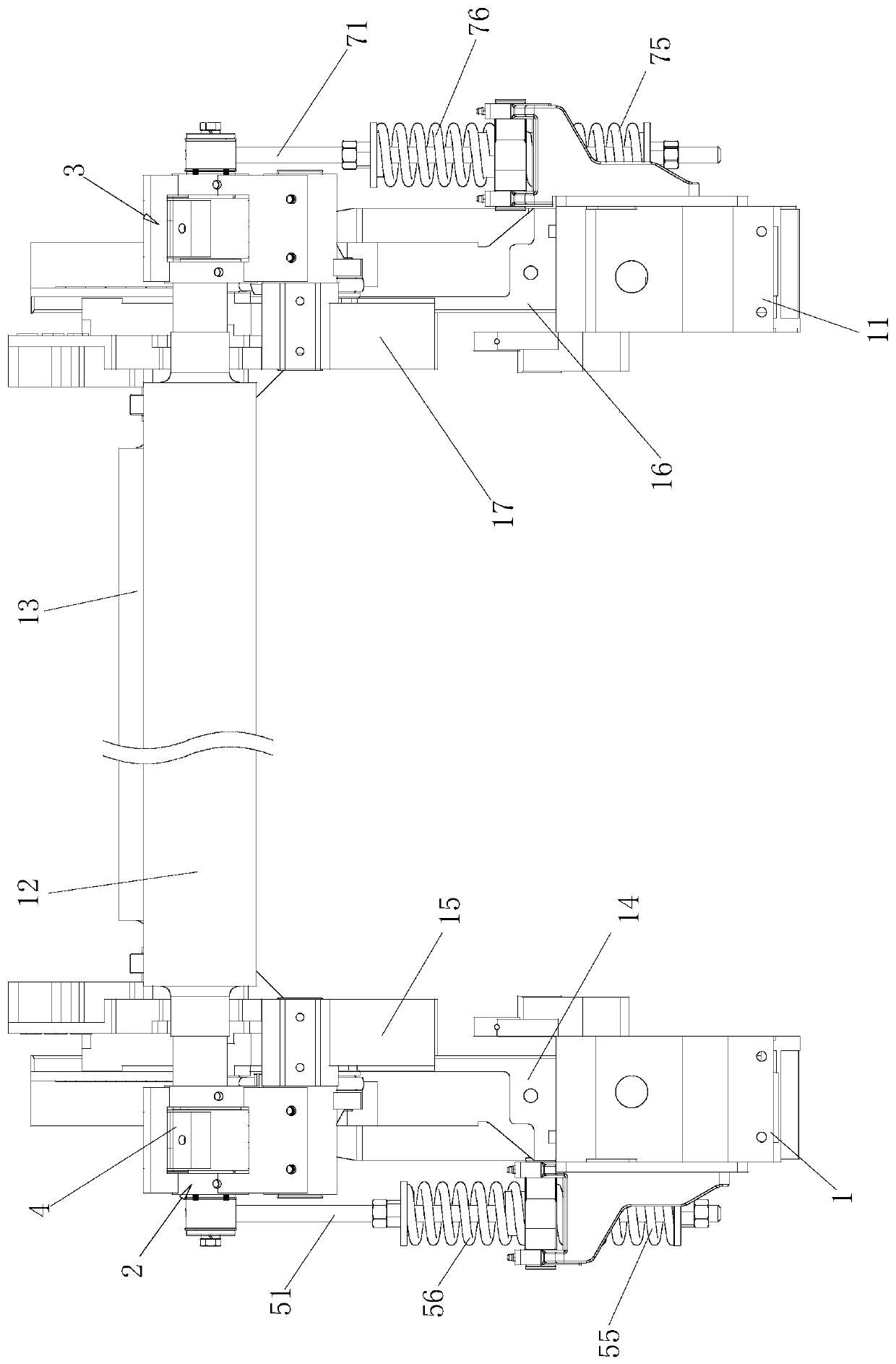

[0051] combine Figure 1 to Figure 7 , a tension control device suitable for light fabrics, including a left frame 1, a right frame 11, a tension roller 12 and a transition roller 13. The left frame 1 is connected with a left roller support 15 through a left elevating support 14 , and the right roller support 17 is connected with a right elevating support 16 on the right frame 11 .

[0052] The top of the left roller support 15 is connected with the left buffer linkage mechanism 2, the top of the left buffer linkage mechanism 2 is connected with the left end of the tension roller 12 in rotation, and the bottom of the left buffer linkage mechanism 2 is connected with the left frame 1 positioning.

[0053] The top of the right roller bracket 17 is connected with a right buffer linkage mechanism 3, the top of the right buffer linkage mechanism 3 is connected with the right end of the tension roller 12, and the bottom of the right buffer linkage mechanism 3 is positioned and conne...

Embodiment 2

[0078] combine Figure 1 to Figure 7 When the above-mentioned tension control device suitable for light fabrics is in operation, the warp yarn on the weaving beam 8 passes upward through the transition roller, then forward through the tension roller, and passes through the heald structure 81 to reach the weaving fell.

[0079] There are two states of warp passing:

[0080] The first type is the warp route in the heald state: the points A-B0-C0-D0-E0-F-G where the warp passes through;

[0081] The second type, the warp route in the opening state of the weaving fell:

[0082] The point through which the upper warp of this type passes is: A-B1-C1-D1-E1-F-G; the point through which the lower warp of this type passes is: A-B2-C2-D1-E1-F-G;

[0083] The warp yarn route lengths of the upper and lower layers are slightly different, and the tension of the upper and lower layers has little influence when the tension roller opens.

[0084] When the loom is opened and closed, the tensi...

Embodiment 3

[0088] combine Figure 1 to Figure 7 , in the above-mentioned tension control device suitable for light-duty fabrics, the tension roller is above the transition roller, leaning slightly forward (diagram Φ2), forming a larger wrap angle (diagram Φ1), so that the cloth fell A When switching between opening and closing, the tension roller only needs a small swing range to compensate for the warp variation between opening and closing. In this way, the tension roller follows the state better when running at high speed, and the tension change is relatively small.

[0089] The position of the fulcrum of the swing arm of the tension roller is slightly forward on the upper part of the roller, and the center of the fulcrum, the center of the tension roller, and the center of the transition roller are close to a straight line of 180°, so that when the tension roller swings, the tension roller The length of the rear warp rarely changes, because the tension roller does not rotate automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com