A kind of rapid cooling equipment for castings

A rapid cooling and casting technology, applied in the field of casting cooling, can solve the problem of insufficient cooling effect of castings and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

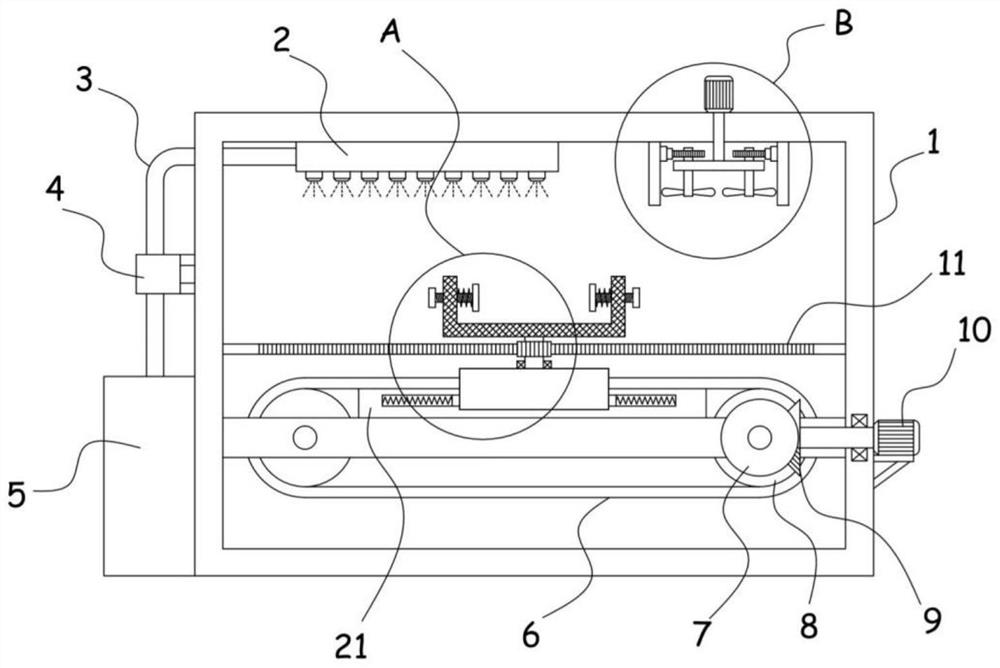

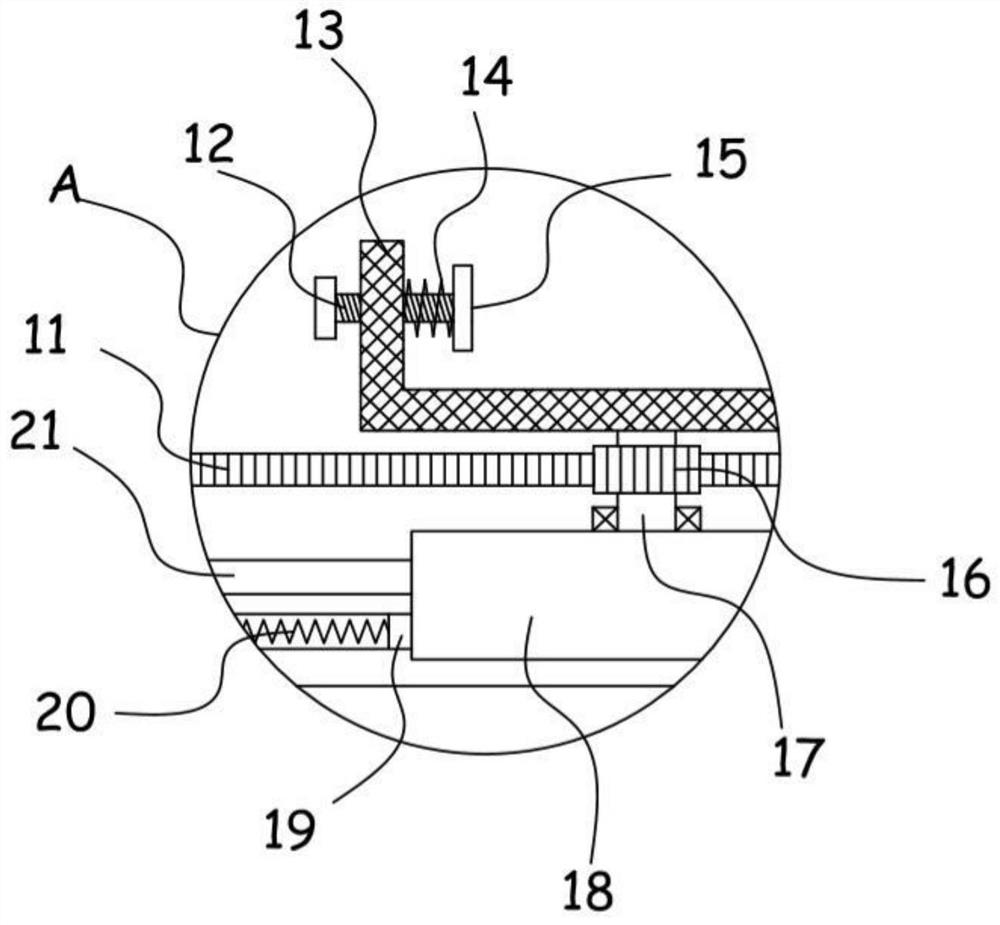

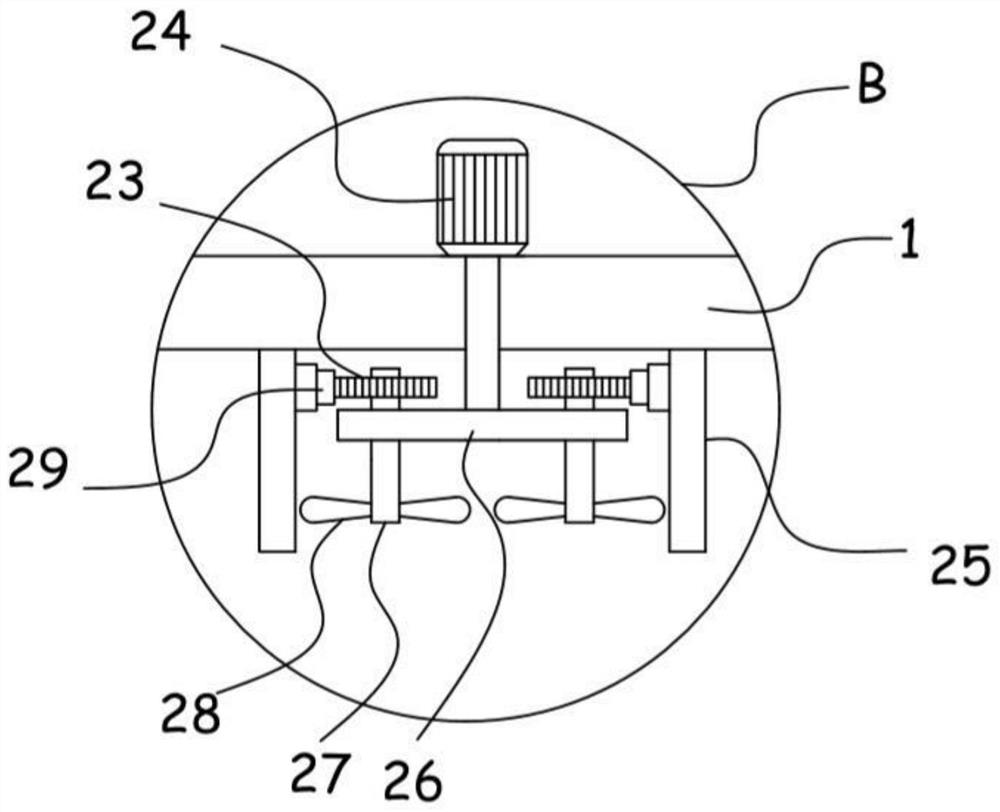

[0026] see Figure 1-5 , a kind of rapid cooling equipment for castings, comprising a support frame 1, a drive motor 10 is fixed on the side wall of the support frame 1, a pulley 8 is mounted on the support frame 1, and a transmission belt 6 is sleeved on the pulley 8, and the support frame 1 is provided with a steering mechanism for driving the belt pulley 8 to rotate counterclockwise. The belt pulley 8 is provided with a support plate 21 for supporting it. A translation mechanism fixed to the belt pulley 8 is slidably installed on the support plate 21. The translation The mechanism is provided with a fixing mechanism for clamping the casting, the support frame 1 is fixed with a water tank 5, and the water tank 5 is connected and installed with a water cooling mechanism for spraying the casting, and the top of the support frame 1 is fixed with a servo The motor 24 and the servo motor 24 are driven and connected with an air cooling mechanism for cooling the casting.

[0027] ...

Embodiment 2

[0032] On the basis of Embodiment 1, in addition, the device is also provided with a steering mechanism, including an incomplete bevel gear 9 coaxially fixed with the output shaft of the drive motor 10, and the incomplete bevel gear 9 is alternately meshed with a belt pulley 8 coaxial Fixed bevel gear I7 and bevel gear II22.

[0033] The drive motor 10 is used to drive the incomplete bevel gear 9 to rotate, and the incomplete bevel gear 9 alternately meshes with the bevel gear I7 and the bevel gear II22 for transmission. At this time, the belt pulley 8 alternately rotates clockwise and counterclockwise to realize the lateral position of the transmission belt 6 driving the translation mechanism. Moving, the translation mechanism drives the casting to be cooled by the water-cooling mechanism when it moves to the far left, and the casting is cooled by the air-cooling mechanism when it moves to the far right, which greatly improves the cooling efficiency.

[0034] Further, the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com