An Oxygen Safety System for an Underwater Unmanned Airtight Cabin

A closed cabin, safety technology, applied in underwater operation equipment, ships, transportation and packaging, etc., can solve the problems of pipeline valve damage or sealing failure, increase and increase of pressure in sealed cabins, etc., to ensure single-phase Emissions, Fire and Explosion Prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

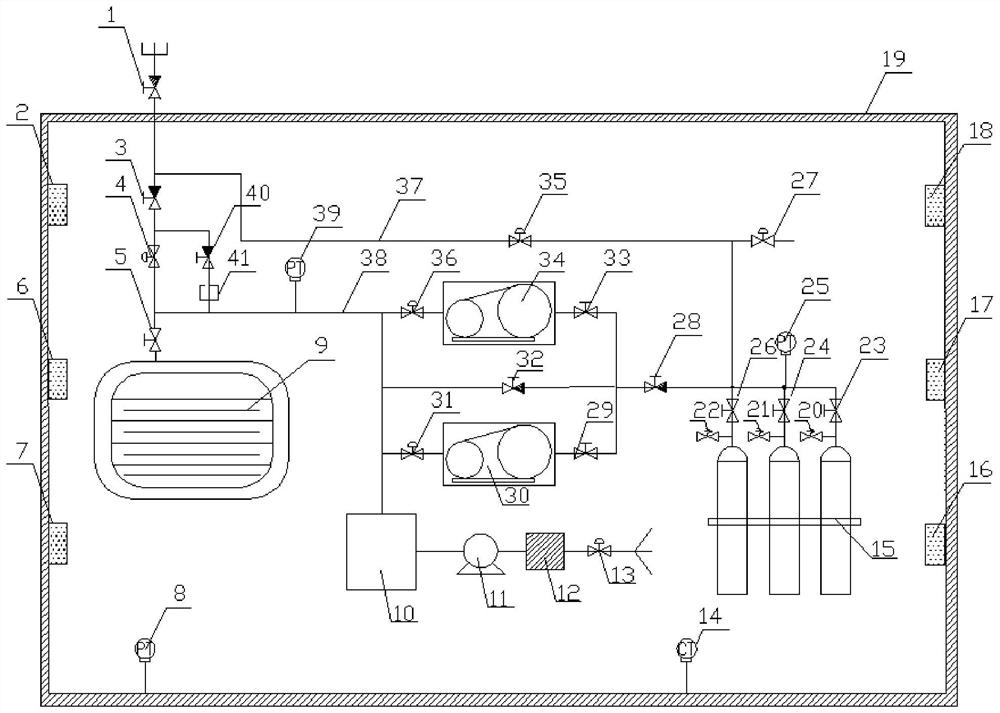

[0035] Such as figure 1 As shown, the oxygen safety system device of the underwater unmanned airtight cabin of the present embodiment comprises a pressure-resistant airtight cabin 19, the inner wall of the pressure-resistant airtight cabin 19 is provided with multiple groups of oxygen scavengers, and the outside of the pressure-resistant airtight cabin 19 A sea-connecting one-way valve 1 is provided, and the outlet of the sea-connecting one-way valve 1 enters the interior of the pressure-resistant airtight chamber 19 through a pipeline. This pipeline is connected to the liquid oxygen storage tank 9, and the first one-way valve 3 is also connected in series on this pipeline. , the first pneumatic valve 4 and the first shut-off valve 5;

[0036] The pipeline between the sea-opening one-way valve 1 and the first one-way valve 3 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com