Sparse reconstruction method for micro-defect high-frequency ultrasonic microscopic imaging based on blind estimation

A technology of microscopic imaging and sparse reconstruction, which is applied in the field of image processing, can solve the problems of gap, sparse reconstruction of echo signals, limited processing equipment time, poor applicability, etc., to improve accuracy and efficiency, and improve applicability and practicality, enhancing the effect of image signal-to-noise ratio and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

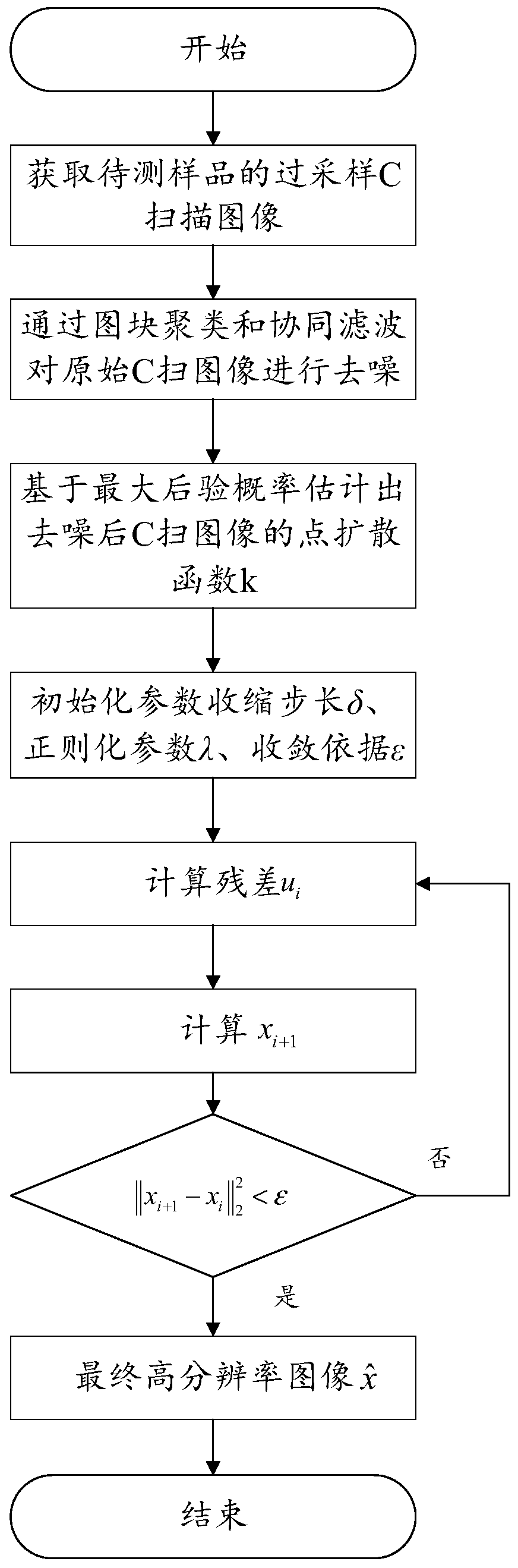

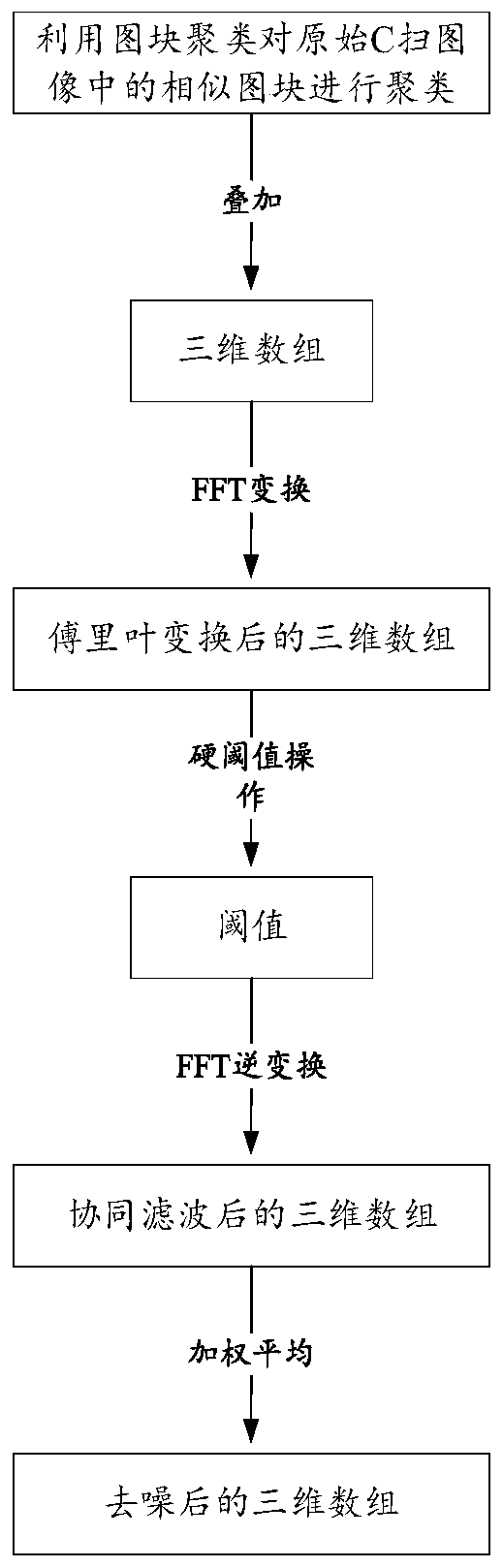

[0053] This application discloses a sparse reconstruction method for high-frequency ultrasonic microscopic imaging of small defects based on blind estimation. Please refer to figure 1 , the method includes the following steps:

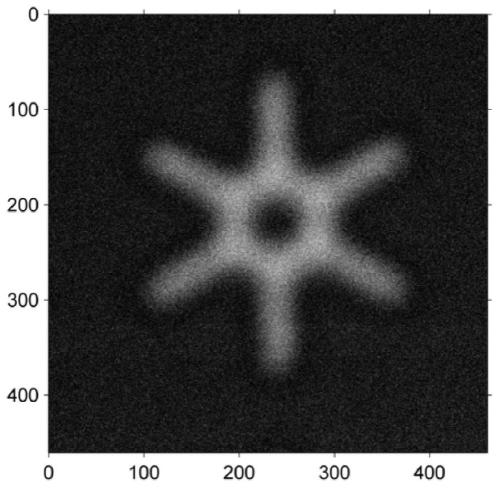

[0054] Step 1: Use an ultrasonic microscopic imaging system (SAM, D9500, Sonoscan, Elk Grove Village, IL, USA) to obtain the original C-scan image of the sample to be tested, the sampling step size s is 1 μm, and the ultrasonic probe frequency is 230 MHz (230SP probe ). The point spread function of the ultrasonic probe of the ultrasonic microscopic imaging system does not change with the change of the space-time position of the measured object, and the ultrasonic probe is a high-frequency focused ultrasonic probe with a frequency of 100 MHz or above. figure 2 is the original C-scan image constructed according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com